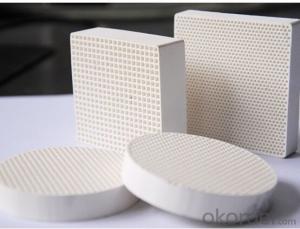

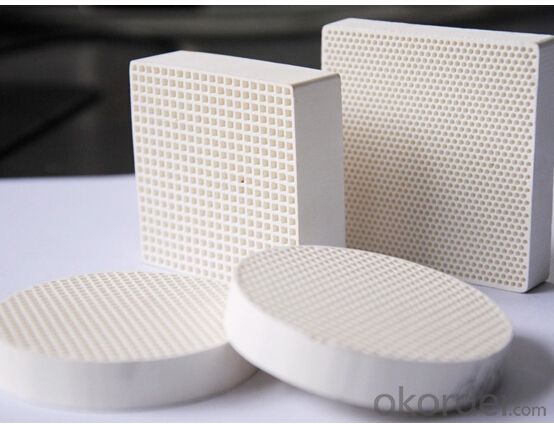

Alumina Ceramic Filter Plate Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

APPLICATION:For the filtration of molten aluminum and non ferrous alloy.

Alumina Ceramic Foam Filters mainly for filtration of aluminum and alloys in foundries and cast houses .With the excellent

resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas

and provide laminar flow and then the filtered metal is significantly cleaner.Cleaner metal results in higher-quality castings,

less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas

and provide laminar flow and then the filtered metal is significantly cleaner.Cleaner metal results in higher-quality castings,

less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

FEATURES:

*Superior dimensional tolerances

*Stable chemical composition

*Highest filtration efficiency

*Excellent strength

*Resistant to corrosion attack by molten aluminum and alloys

*Beveled edges and compressible gasket

SPECIFICATION:

Color:White

Working Temp :≤1100°C

Porosity:80~90%

PPI(pores per inch):10/20/30/40

PPI(pores per inch):10/20/30/40

Compression Strength (Room Temperature) :≥0.8Mpa

Volume Density: 0.36-0.5g/cm3

Thermal Shock Resistance:1100°C to room temperature 6 times

COMMON SIZES:

7x7x2" (178x178x50mm)

9x9x2" (229x229x50mm)

12x12x2" (305x305x50mm)

15x15x2" (381x381x50mm)

17x17x2" (432x432x50mm)

20x20x2" (508x508x50mm)

23x23x2" (584x584x50mm)

7x7x2" (178x178x50mm)

9x9x2" (229x229x50mm)

12x12x2" (305x305x50mm)

15x15x2" (381x381x50mm)

17x17x2" (432x432x50mm)

20x20x2" (508x508x50mm)

23x23x2" (584x584x50mm)

*Other sizes can be customized upon request.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What are the materials that make up the ceramic mold?

- From the development trend of rice, the development of ceramic membrane preparation technology mainly in the following 2 aspects: one is the porous membrane research, to further improve the already commercialized inorganic ultrafiltration and microfiltration membrane, nanofiltration membrane with molecular sieve, the development function of gas separation membrane and pervaporation membrane: two in dense membrane research solid electrolyte membrane, ultra-thin metal and its alloy film and ion conduction ability is research hotspot. The commercial porous membranes are mainly ultrafiltration and microfiltration membranes, and their preparation methods are mainly particle sintering and sol-gel. The former is mainly used for making microporous filter membranes, and commercial A1203 films are prepared by particle sintering method.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What are the reasons for the program alarm of ceramic filter?

- If that is the ceramic filter tank body of the slurry concentration is diluted, has nothing to do with the ceramic filter itself, can think of ways to enter the ceramic filter tank before the slurry concentration increased, thereby improving the dewatering efficiency of ceramic filter.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q: How should the static and dynamic sealing points of the ceramic filter be leaking?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

Send your message to us

Alumina Ceramic Filter Plate Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords