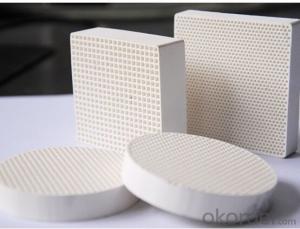

Ceramic Filter Plate for Non Ferrous Alloy Alumina Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

APPLICATION:For the filtration of molten aluminum and non ferrous alloy.

Alumina Ceramic Foam Filters mainly for filtration of aluminum and alloys in foundries and cast houses .With the excellent

resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas

and provide laminar flow and then the filtered metal is significantly cleaner.Cleaner metal results in higher-quality castings,

less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas

and provide laminar flow and then the filtered metal is significantly cleaner.Cleaner metal results in higher-quality castings,

less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

FEATURES:

*Superior dimensional tolerances

*Stable chemical composition

*Highest filtration efficiency

*Excellent strength

*Resistant to corrosion attack by molten aluminum and alloys

*Beveled edges and compressible gasket

SPECIFICATION:

Color:White

Working Temp :≤1100°C

Porosity:80~90%

PPI(pores per inch):10/20/30/40

PPI(pores per inch):10/20/30/40

Compression Strength (Room Temperature) :≥0.8Mpa

Volume Density: 0.36-0.5g/cm3

Thermal Shock Resistance:1100°C to room temperature 6 times

COMMON SIZES:

7x7x2" (178x178x50mm)

9x9x2" (229x229x50mm)

12x12x2" (305x305x50mm)

15x15x2" (381x381x50mm)

17x17x2" (432x432x50mm)

20x20x2" (508x508x50mm)

23x23x2" (584x584x50mm)

7x7x2" (178x178x50mm)

9x9x2" (229x229x50mm)

12x12x2" (305x305x50mm)

15x15x2" (381x381x50mm)

17x17x2" (432x432x50mm)

20x20x2" (508x508x50mm)

23x23x2" (584x584x50mm)

*Other sizes can be customized upon request.

- Q: Performance advantages of ceramic filter

- The base is provided with a slime recovery rotor, the rotor consists of a shaft, multistage ceramic filter disc, stripper plate, multi section water connecting pipe, pipe support plate, negative pressure connecting component dynamic disk; the rotor is in the recovery of coal slime liquid tank; the ceramic filter disc by a plurality of ceramic microporous plate cavity, located on the same axis of a ceramic plate cavity communicated through the outlet connection pipe.

- Q: Influence factors of ceramic filter

- (1) the particle size and the distribution of the material match the microporous of the ceramic filter plate. Although the ceramic filter plate aperture is bigger, easy to suck the pulp, but easy to cause the ceramic filter board to block up.(2) the ceramic filter plate with the same ceramic filter plate with high pore permeability and high water permeability is selected with high water permeability and good slurry absorption performance. The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.

- Q: Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What's the reason for high water content in filtration copper concentrate?

- Can the cleaning of ceramic plate meet the requirement?Such as cleaning of ceramic plate is not up to the requirements, plugging holes will increase the risk of ceramic plate, ceramic plate plug serious suction effect will become worse (filter cake moisture content increased, cake thickness reduction), cleaning of ceramic plate refers to washing and cleaning.Backwash to ensure that the water filter filter water pressure in the 0.1MPa or so, at least not less than 0.07MPa or less, it is necessary to consider before the filter water pressure is low or water filter element needs to be replaced.Joint cleaning to ensure that the ultrasonic can be no trouble, every time cleaning the amount of nitric acid up to standard. If the filtration effect is not ideal, the cleaning cycle can be washed from 45--60 every 8 hours, changed to 6--7 hours and cleaned for more than 1 hours.

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

- Q: Can the ceramic plate filter the hot air?

- Ceramic filter by vacuum suction effect in the ceramic filter plate to cake drying purpose, ceramic filter plate needs cleaning and life, if you discover that the slurry sucking effect is poor or even grout should first consider the three aspects: the two factors of ceramic filtering plate of ceramic filter plate most likely, are fracture and hole plugging: rupture will lead to distortion and poor vacuum cleaning; plugging holes will cause the filter plate suction effect is poor even if grout, ceramic filter plugging hole, can strengthen the appropriate cleaning (such as shortening cleaning cycle, prolong the cleaning time, increase the amount of nitric acid, such as strengthening cleaning etc.) after the effect is still not improved, you should consider the life is approaching should be scrapped and replaced with ceramic filter plate new (replacement plate should not put new or different manufacturers is mounted on the same line, the most OK, complete replacement.).

Send your message to us

Ceramic Filter Plate for Non Ferrous Alloy Alumina Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords