Ceramic Filter Plate 1 - High Quality Ceramic Filter Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100Pcs pc

- Supply Capability:

- 2000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

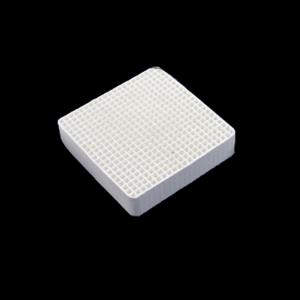

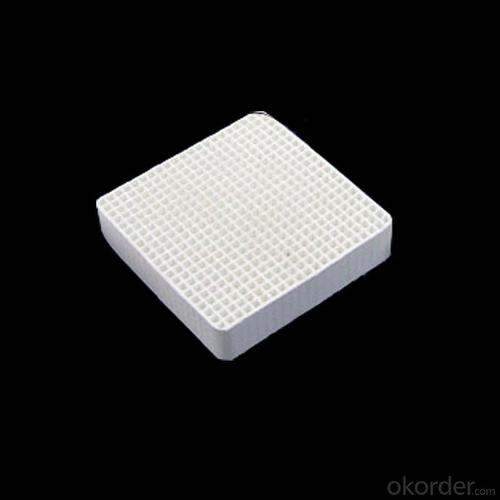

General Information of Ceramic Filter Plate

CMAX ceramic filter plate is made from high purity alumina silicate fibers mixing with inorganic binders by vacuum forming process. It is widely used in aluminum alloy melting furnace to control the production flow of molten aluminum. CMAX ceramic Filter Plate is a kind of large porous ceramic disc which is fired by inorganic membrane making technology. Regarding firing process, traditionally the ceramic plate is consisted of two layers of plates which are glued together to form inner channels. But after long term running, the glue will block the pores to cause flower spots on the surface of the plates.

Characteristic of CMAX Ceramic Filter Plate:

Good thermal insulation

Durable mechanical strength

High strength, abrasion and corrosion resistantance and long service life.

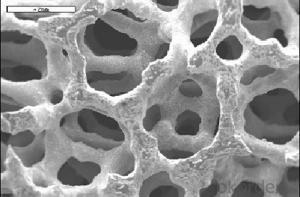

Size of micropore is small (normally with diameter of 1.0um), strong capillary effect.

Low power and energy consumption as filter rates drawn into micropore automatically.

High filtration pressure drop (vacuum degree can reach-0.098Mpa) and low moisture of filter cake.

Filtrate is clear and transparent with low suspended substances (21ppm), Filtrates can be used as industrial circulation water

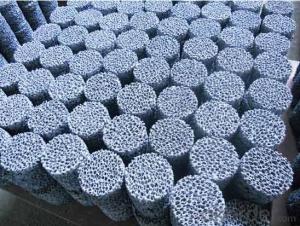

Application of CMAX Ceramic Filter Plate:

Aluminum alloy melting furnace for die casting industry

Other shapes like sleeves or risers for sand casting foundry

the application can be divided into two types, one is used for the two phase separation, the other is to disperse a phase to another, that is to combine the two, especially for liquid filtration, gas filtration, fluidization, etc..

CNBM has success in its ceramic filter plate products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic filter plate application and would like to assist you in product selection, system design, and installation techniques. Our products of ceramic filter plateare in good quality and in best price.

- Q: What filter material are placed in the aquarium filter?

- Generally let off the filter cotton and ceramic rings, there are biochemical balls, coral bone, stone, activated carbon and so onConditional: filter cotton, ceramic ring, biochemical ball, coral bone, stone, activated carbon

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- Ceramic filter is mainly composed of system, roller system, mixing discharge system, vacuum system, liquid discharge system, scraper system, washing system, cleaning system, automatic control system, and these parts body frame.

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: What's the reason for high water content in filtration copper concentrate?

- Can the cleaning of ceramic plate meet the requirement?Such as cleaning of ceramic plate is not up to the requirements, plugging holes will increase the risk of ceramic plate, ceramic plate plug serious suction effect will become worse (filter cake moisture content increased, cake thickness reduction), cleaning of ceramic plate refers to washing and cleaning.Backwash to ensure that the water filter filter water pressure in the 0.1MPa or so, at least not less than 0.07MPa or less, it is necessary to consider before the filter water pressure is low or water filter element needs to be replaced.Joint cleaning to ensure that the ultrasonic can be no trouble, every time cleaning the amount of nitric acid up to standard. If the filtration effect is not ideal, the cleaning cycle can be washed from 45--60 every 8 hours, changed to 6--7 hours and cleaned for more than 1 hours.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- There may be a fault filtrate pump, diaphragm pump damage, pump mechanical seal failure, a leak, two is no output or output to the liquid, the pressure is too low, the cleaning effect is not good, the pressure is too large, will cause damage and reduce the concentration of slurry filter plate.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter boards tend to clog and acid washing is used to dissolve and dredge blockages in their pores.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: How should the static and dynamic sealing points of the ceramic filter be leaking?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Asia;America; Africa; Europe; and so on |

| Company Certifications | Quality management system certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 21-50 pepole |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 230,000 square meters |

| No. of Production Lines | 37 lines |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Filter Plate 1 - High Quality Ceramic Filter Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100Pcs pc

- Supply Capability:

- 2000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords