High Quality Ceramic Filter Plate - Silica Ceramic Foam Filter Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter

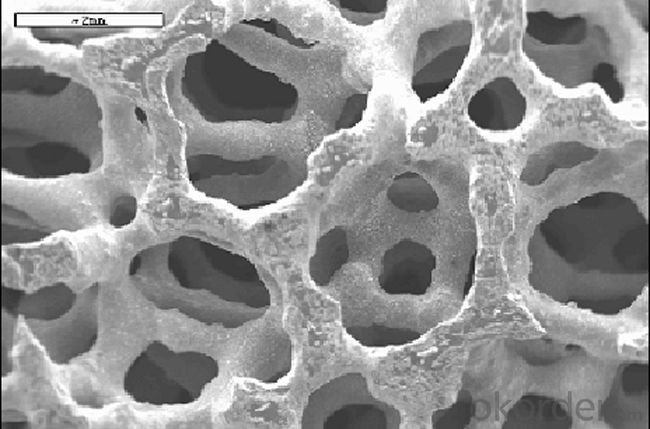

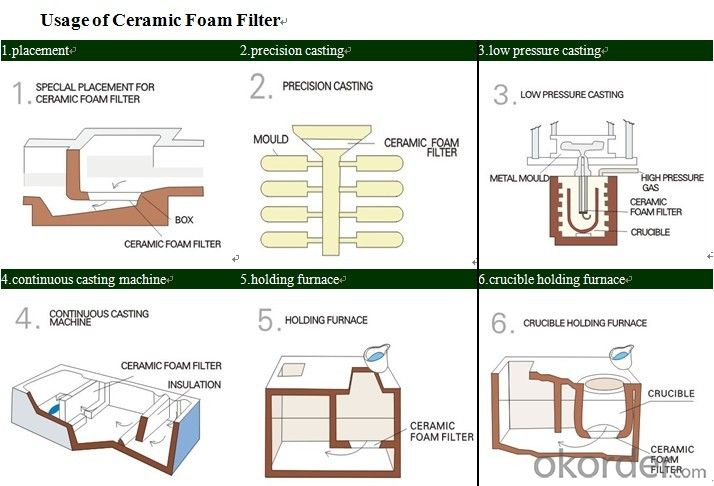

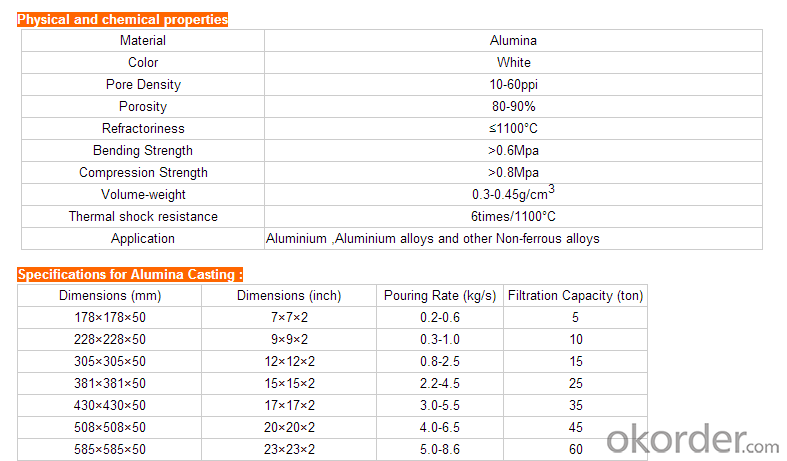

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream.Additionally, they aid in reducing turbulence in the gating system.

SIC ceramic foam filter's outstanding thermal shock resWe have a factory manufacturing foam ceramic filter, Main products include:

1. CFA (Alumina Foam Ceramic Filter)

2. CFS (Silicon Carbide Foam Ceramic Filter)

3. CFZ (Zirconia Foam Ceramic Filter)

4. CFM (Magnesia Foam Ceramic Filter)

5. Honeycomb Ceramic Filter

Product Applications:

Zirconia ceramic foam filters apply to purge and filter solution of carbon steel, steel alloy and stainless steel.

Product Advantages:

Reduce imparities of the castings

Improve casting quality rate

Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Main Product Features:

We have a factory manufacturing foam ceramic filter, Main products include:

1. CFA (Alumina Foam Ceramic Filter)

2. CFS (Silicon Carbide Foam Ceramic Filter)

3. CFZ (Zirconia Foam Ceramic Filter)

4. CFM (Magnesia Foam Ceramic Filter)

5. Honeycomb Ceramic Filter

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

Product Picture

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- The filter plate of ceramic filter is afraid of frost and should be protected.

- Q: How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q: Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Oxalic acid immersion:For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

- Q: What are the functions of honeycomb ceramic filters?

- High quality and high density straight hole mesh, the product has high heat resistance and impact resistance properties of cast high fever temperature, design straight hole to guarantee the balance between strength and flow, effectively remove impurities and slag particles, the mechanical properties of casting, the surface quality and the qualified rate of products is greatly improved.

- Q: How should the static and dynamic sealing points of the ceramic filter be leaking?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

Send your message to us

High Quality Ceramic Filter Plate - Silica Ceramic Foam Filter Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords