Low Price Ceramic Filter Plate - Ceramic Foam Filter Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter

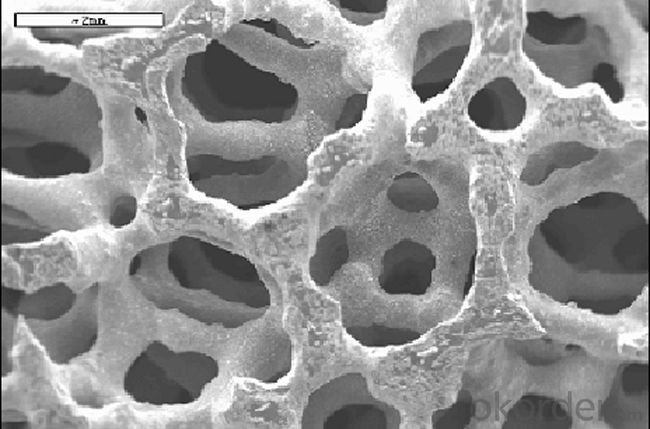

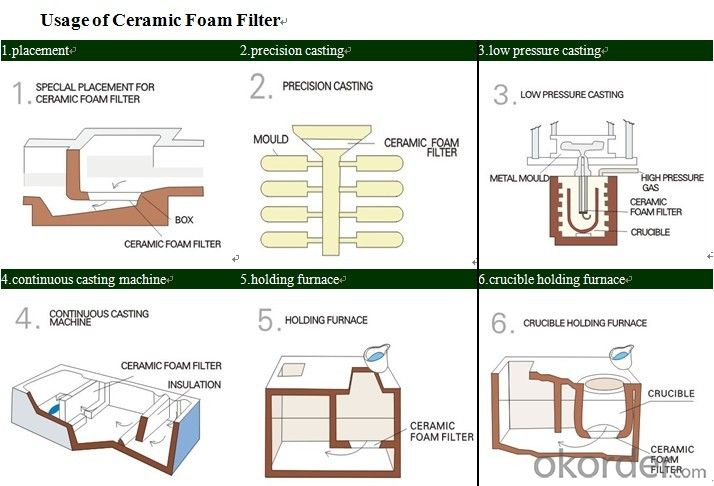

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream.Additionally, they aid in reducing turbulence in the gating system.

SIC ceramic foam filter's outstanding thermal shock resWe have a factory manufacturing foam ceramic filter, Main products include:

1. CFA (Alumina Foam Ceramic Filter)

2. CFS (Silicon Carbide Foam Ceramic Filter)

3. CFZ (Zirconia Foam Ceramic Filter)

4. CFM (Magnesia Foam Ceramic Filter)

5. Honeycomb Ceramic Filter

Product Applications:

Zirconia ceramic foam filters apply to purge and filter solution of carbon steel, steel alloy and stainless steel.

Product Advantages:

Reduce imparities of the castings

Improve casting quality rate

Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Main Product Features:

We have a factory manufacturing foam ceramic filter, Main products include:

1. CFA (Alumina Foam Ceramic Filter)

2. CFS (Silicon Carbide Foam Ceramic Filter)

3. CFZ (Zirconia Foam Ceramic Filter)

4. CFM (Magnesia Foam Ceramic Filter)

5. Honeycomb Ceramic Filter

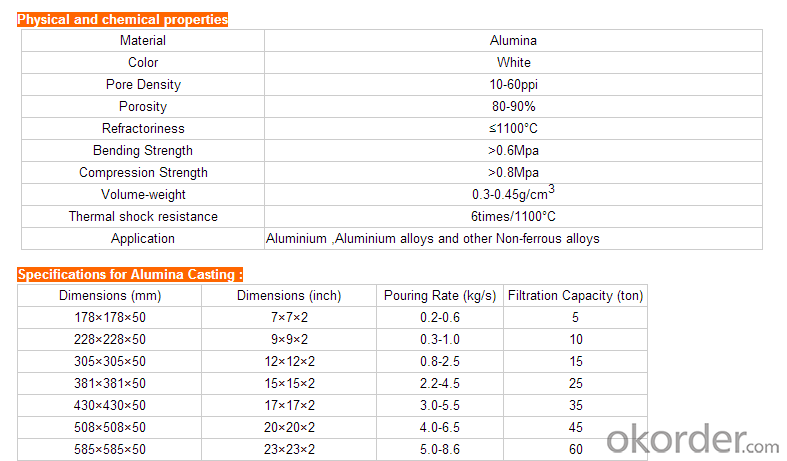

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

Product Picture

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- That's a good question. I hope my answer will help you.Ceramic filter ceramic plate broken, nothing more than ceramic plate plug and ceramic plate rupture, you should be the problem of ceramic plate rupture.

- Q: What are the poor filtration effects of vacuum disc filters?

- With the increase of the material level of the ceramic filter trough, the suction time of the ceramic filter plate in the vacuum zone increases, the thickness of the slurry increases and the productivity increases. But the drying time is relatively short, the water content of the concentrate will be increased. Select the best material level to ensure the production capacity and concentrate moisture requirements.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: Common troubles of ceramic filter

- Ultrasonic cleaning, ceramic filter plate cleaning is not clean. The main reason is that the power box is faulty, the power supply is burned out, the line is aging, the energy head is burned out, the ultrasonic box is broken down, and the water level in the pulp tank is too low;

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

Send your message to us

Low Price Ceramic Filter Plate - Ceramic Foam Filter Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords