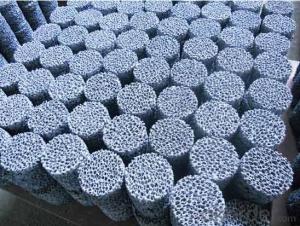

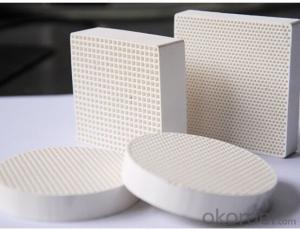

Ceramic Foam Filter

1. Introduction:

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Ceramic Foam filters are just developed as a new type molten metal filter to decrease casting flaw in recent years. With its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance,SIC Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, Bronze casting, etc.

2. Size available:

7", 9", 12", 15", 17", 20", and 23", with porosities from PPI 10 to PPI 60(PPI ie pores per inch).

Other special sizes could be produced on request.

3. Material Specifications

4.1 SIC Physical Properties:

Porosity(%) | 80~90% |

Working Temperature | ≤1500°C |

Bending Strength(Mpa) | 0.8 |

Compression Strength(Mpa) | 0.9 |

Thermal Shock Resistance | 1100°C---room temperature 6 times |

Volume Density | 0.4-0.5g/cm3 |

4.2 Alumina Physical Properties:

Working | ≤1200°C |

Porosity | 80~90% |

Compression Strength | ≥1.0Mpa |

Volume Density | ≤0.5g/cm3 |

Thermal Shock Resistance | 800°C---Indoor temperature 5 times |

Application | non-ferrous and alumina alloys, |

5. Pouring Rate and Filtration Capacity

1) Alumina Ceramic Foam Filters

| Dimensions(mm) | Dimensions(inch) | Pouring Rate(kg/s) | Filtration Capacity(ton) |

| 178x178x50 | 7x7x2 | 0.2-0.6 | 5 |

| 228x228x50 | 9x9x2 | 0.3-1.0 | 10 |

| 305x305x50 | 12x12x2 | 0.8-2.5 | 15 |

| 381x381x50 | 15x15x2 | 2.2-4.5 | 25 |

| 430x430x50 | 17x17x2 | 3.0-5.5 | 35 |

| 508x508x50 | 20x20x2 | 4.0-6.5 | 45 |

| 585x585x50 | 23x23x2 | 5.0-8.6 | 60 |