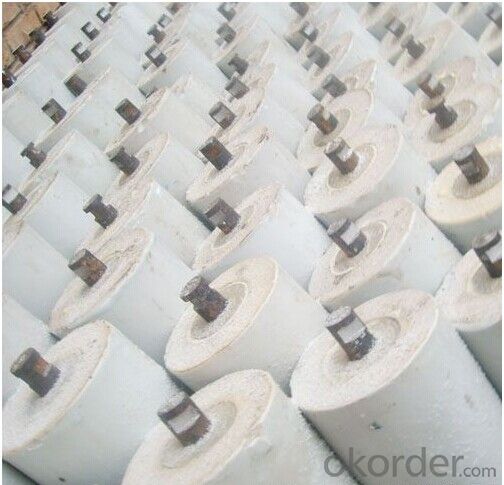

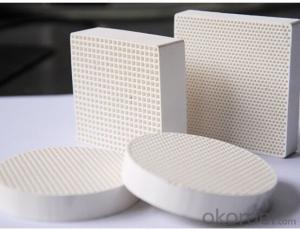

Ceramic Filter Plate Ceramic Roller for Kiln

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.High hardness

2.Good toughness

3.High density

4.Good erosion resistance

5.Regular shape

This product passed the inspection of National Testing Center for Supervising the Quality of Refractory Materiales. It accords with the national JC41491 standard. High temperature resistant, shock resistant, counter bending. Providing manufacturers with stable and durable firing environment circumstance.

| Item | Unit | OK969 | OK989 |

| Color of mark | Yellow | Red | |

| Max.Service Temp. | .C | 1220 | 1350 |

| AL2O3 Content | % | >72 | >81 |

| Rate of Water Absorption | % | <11 | <8.5 |

| Anti-bending strength | Mpa | >40 | >51 |

| Thermal Shock Resistance | Excellent | Excellent | |

| Refractory Degree | .C | >1700 | >1800 |

| Diameter(mm) | Length(mm) |

| 65-68 | 3000-5000 |

| 60 | 2700-5000 |

| 55 | 2700-5000 |

| 50 | 2400-4600 |

| 45 | 2200-3800 |

| 42 | 2200-3800 |

| 40 | 2000-3500 |

| 36 | 2000-3200 |

| 35 | 1800-3100 |

| 33.7 | 1800-3100 |

| 32 | 1800-3100 |

| 25-31 | 1600-3100 |

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q: What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- That's a good question. I hope my answer will help you.Ceramic filter ceramic plate broken, nothing more than ceramic plate plug and ceramic plate rupture, you should be the problem of ceramic plate rupture.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- In addition, the temperature is one of the factors affecting the filter suction effect of ceramic filter. The lower the temperature, the worse the suction effect.Therefore, the ceramic filter plate, especially the ceramic filter plate after use, should be protected under low temperature environment.

- Q: What are the causes of the powder moisture in the ceramic filter?

- Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: Common troubles of ceramic filter

- The metering pump is not working properly and backwash water into the bucket of acid. The main reason is that the metering pump is not switched on, the diaphragm is worn out, the frequency is too low, and the check valve of the acid pipe and backwash pipe is worn out.

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor. Other questions about ceramic filter, welcome to chat with me or look at my head

Send your message to us

Ceramic Filter Plate Ceramic Roller for Kiln

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches