Ceramic Filter Plate 4 - High Quality Ceramic Filter Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100Pcs pc

- Supply Capability:

- 2000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

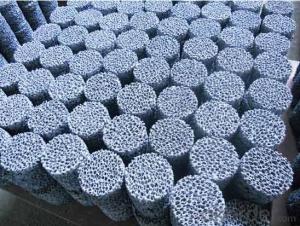

General Information of Ceramic Filter Plate

CMAX ceramic filter plate is made from high purity alumina silicate fibers mixing with inorganic binders by vacuum forming process. It is widely used in aluminum alloy melting furnace to control the production flow of molten aluminum. CMAX ceramic filter plate is made from high purity alumina silicate fibers mixing with inorganic binders by vacuum forming process. It is widely used in aluminum alloy melting furnace to control the production flow of molten aluminum

Feature of Ceramic Filter Plate

Good thermal insulation

Durable mechanical strength

High strength, abrasion and corrosion resistantance and long service life.

Size of micropore is small (normally with diameter of 1.0um), strong capillary effect.

Low power and energy consumption as filter rates drawn into micropore automatically.

High filtration pressure drop (vacuum degree can reach-0.098Mpa) and low moisture of filter cake.

Filtrate is clear and transparent with low suspended substances (21ppm), Filtrates can be used as industrial circulation water

Application of Ceramic Filter Plate

Aluminum alloy melting furnace for die casting industry

Other shapes like sleeves or risers for sand casting foundry

the application can be divided into two types, one is used for the two phase separation, the other is to disperse a phase to another, that is to combine the two, especially for liquid filtration, gas filtration, fluidization, etc..

CNBM has success in its ceramic filter plate products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic filter plate application and would like to assist you in product selection, system design, and installation techniques. Our products of ceramic filter plateare in good quality and in best price.

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q: How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- Water glass is a kind of adhesive of flotation reagent, after use may cause the pulp viscosity increased, leading to the adsorption resistance of slurry becomes large, when using ceramic filter filtration dewatering, vacuum suction surface of the microporous ceramic filter plate is smaller than the resistance, there may be a suction effect or even not suction. Some flocculant agents can lead to this phenomenon.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter. I analyze the reasons from two aspects.

- Q: Microporous ceramic filter plate cleaning

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Replace ceramic filter plate:Different users because of pulp particle size and different characteristics, the service life is long and short of ceramic filtering plate. For the use of a long time and after the method 1 and 2, the effect of slurry suction is still very poor, we should consider replacing the new ceramic filter board.

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

Send your message to us

Ceramic Filter Plate 4 - High Quality Ceramic Filter Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100Pcs pc

- Supply Capability:

- 2000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords