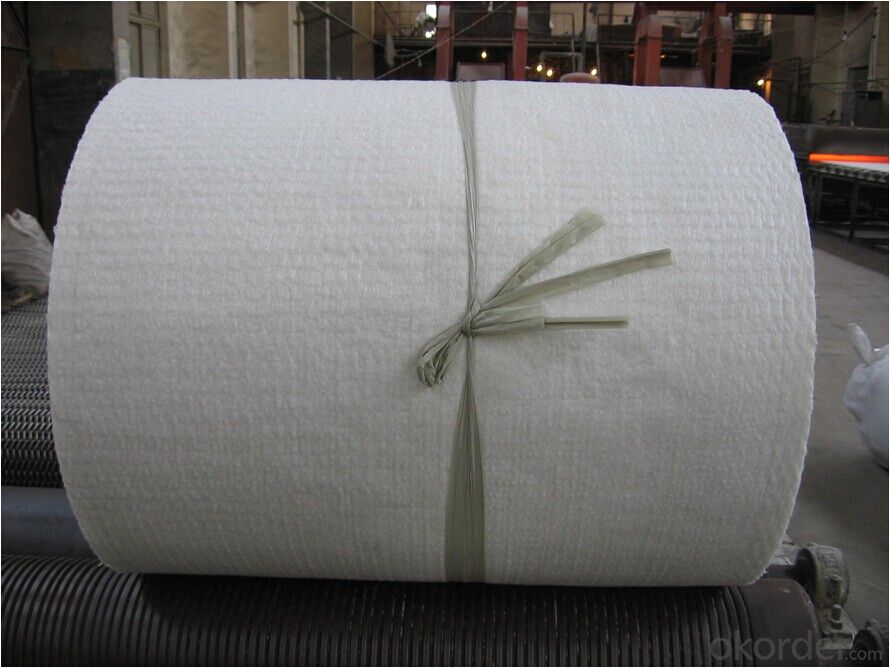

Ceramic Fiber Blanket Needling Aluminum Silicate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 1500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket is made by continuous processing method. The fiber interweave shapely after being needled. It has excellent tensile strength. The blanket do not contains any bonding agent.

Ceramic Fiber Blanket not only can resist the chemical species, but also the hydrofluoric acid, phosphoric acid and strong base. The Fiber Blanket has excellent capability of resisting the oil. After being dried, it will repossess the thermal characteristic and the physical feature.

Ceramic Fiber Blanket Technical Advantages:

-Low heat conductivity and thermal capacity

-Excellent thermal stability and shock resistance

-Strong tensile resistance

-Excellent heat insulation, fireproof and sound insulation

Ceramic Fiber Blanket Applications:

-Industrial kiln, heating device, high-temperature pipeline wall lining.

-Heat insulation of electric boiler, steam turbine and nuclear electricity.

-Wall lining of chemical high-temperature conversion unit and heating equipment.

-Fireproof and heat insulation of tall buildings.

-Heat insulation of kiln door and roofs.

-Materials of high-temperature filtration.

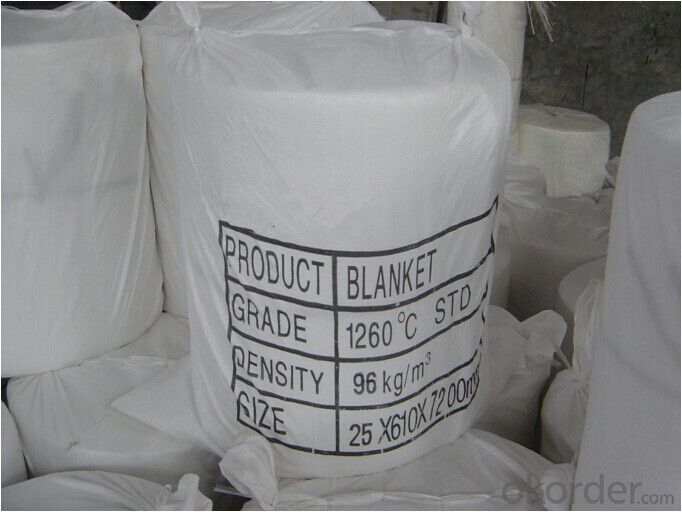

Ceramic Fiber Blanket Product Specifications:

density(kg/m3) | length(mm) | width(mm) | thickness(mm) |

80-128 | 3000-7200 | 610/1220 | 10-60 |

Technical Parameters:

Classification Temperature | 1050 | 1260 | 1400 | ||||

Code | HLGX-112 | HLGX-212 | HLGX-312 | HLGX-422 | HLGX-512 | ||

Shrinkage on Heating (%) | 950°C×24h≤-3 | 1050°C×24h≤-3 | 1100°C×24h≤-3 | 1200°C×24h≤-3 | 1280°C×24h≤-3 | ||

Theoretical Thermal Conductivity (W/m·k)(128kg/m3) | (200°Caverage) | 0.045-0.060 | 0.052-0.070 | ||||

(400°Caverage) | 0.085-0.110 | 0.095-0.120 | |||||

(600°Caverage) | 0.152-0.20 | 0.164-0.210 | |||||

Theoretical Density (kg/m3) | 96/128 | 128 | 96/128 | ||||

Specification (mm) | 3600/7200/15000×610/1220×10/20/25/30/40/50 (422δ: 10/20/25/30) | ||||||

Tensile Strength(25mm thick)MPa | ≥0.04 | ||||||

Package | Plastic Bag Inside, Braided Bag Outside | ||||||

Our Service

Okorder providers various densities and thickness of Ceramic Fiber Blanket, pleases contact us for your needs.

- Q: How To Curl My Hair Like This?

- Use Herstyler 3P Ceramic curler iron set.Its easy and safe to use because of thermal glove that prevent burning and have a good results.Use products that are not too expensive and effective to use.

- Q: What does quasiductile mean?

- Just look them up on google images.

- Q: I rescued my paint mare last SeptShe was already about 100lbs underweight thenShe started picking up weight, then as winter hit, started loosing againNow she is around 200lbs under weightWe've had the vets out regularly checking on herThey've done blood work, check ups and she is wormed on a regular basis with Equi-MaxShe gets 3lbs Safechoice and 2lbs Empower(supplement), she also gets free choice hayWe had a vet out about a month ago, and said if she didn't start picking up weight in a month to call him backWellIts a month later and NO weight changesI will be calling them tomorrow, but does anyone have any other suggestions for me to try with her? She is between the ages of 3 and 4, she has not been worked at all since she came to our farm last SeptWe feed her separate from the other 4 horses, so we know she is getting all of her foodIm so lost at what to do with her!

- Is Equi-Max the only dewormer you use? You need to rotate between different ones to kill different parasitesWhen the vet is out, ask for a fecal egg count so you know what to deworm forYou should also put her on a high-fat feed, such as Triple Crown SeniorAlso, what kind of hay is she getting? If you've been giving her first cutting, try a later, better cutting like 5thOr get a mix with alfalfa, also a later cuttingAdd things like corn oil and beet pulp (soaked!) to her meals as wellIf it's chilly out, blanket her with at least a medium-weight turnout (a sheet will just make her colder).

- Q: I want to make my friend a light yellow yarn tail for her cosplayIs there any way I can stain the tail yellow after I make it so I won't ruin my straightener?

- Not sure you can 'stain' it at allIt depends on what the yarn is made ofIf it's wool, cotton, or some other natural fiber, you'll be able to dye it easilyThe dye won't harm your straightener if the wool is dyed with a real fabric dye, and the excess dye is thoroughly rinsed out of the yarn before the dye is set and the yarn is dried.

- Q: What is ceramic fiber blanket?

- Ceramic fiber blanket is made from aluminum silicate fiber filament through special double needling technique. Fiber’s intertexture degree, delamination resistance, strength of extension and the surface roughness are greatly improved after the special double needling technique.

- Q: he is already in a box with a blanket in the box and another blanket is wrapped around that boxwhat else do i do? i do not have a thermometer so i can not monitor the temperaturei just need more ways to keep him warm.when a kitten meows what is he asking for? i am so nervous and scared he may die.

- We call it the suction tube here, it's probably the slang term but it's widely understand as a suction tube.

- Q: He has 3 blankets on him and his temperature Is still not going upI am sitting here with a t- shirtPlease someone tell me ghat I should go ahead and call his dr.

- Has he just recently got over a cold or the flu? Sometimes a few days after a cold or flu your temperature will drop down quite a bitIs he well? With that temperature, he probably doesn't want blankets on himCall to ask the doctor if he has any symptoms of illness.

- Q: The blow in insulation seems quite expensiveIs there a way to take down the drywall without damaging it, only bc we cannot fit large drywall up the hallway and the stuff already installed is in great shape.

- Make a hole in the drywall wall adequate to get the insulation batts through the wall so the wall and / or floor can be installed behind the wallPatch the wall when doneMake the cut out stud to stud and of the correct heightTake your time and cut it out neatly on the center of the studWhen you are complete behind the wall, screw the removed piece in place with a couple screws and call it an access panelIf you want it to look better run a 1 x 4 around the cut perimeter, over the cut edges, screw only the 1 x 4 in place at the corners and again, call it an access panel.

- Q: I am trying to make a blanket and when I start to crochet, the yarn that has already been crocheted starts to curl up and spiral aroundIt will not stay straightWhy is this?

- definite, ironing your hair popular will harm itThere are some products available which will help preserve it somewhat cut back warmth harm yet base line flat ironing popular will kill your hairI flat iron my hair for a at once type approximately as quickly as each 3 daysthe two days in between I do countless issues like positioned on a head band or positioned it up with a jaw clip.

Send your message to us

Ceramic Fiber Blanket Needling Aluminum Silicate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 1500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords