Ceramic Fiber Blanket for Petrochemical Industrial Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket for Petrochemical Industrial Insulation

Composite of Ceramic Fiber Blanket for Petrochemical Industrial Insulation

Ceramic Fiber Blanket for Petrochemical Industrial Insulation is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket for Petrochemical Industrial Insulation: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket for Petrochemical Industrial Insulation also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Blanket for Petrochemical Industrial Insulation

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket for Petrochemical Industrial Insulation

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

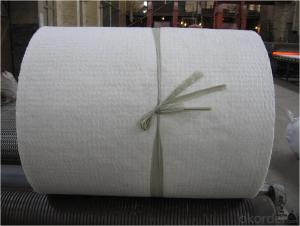

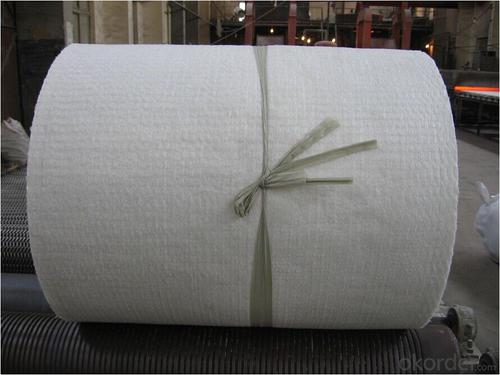

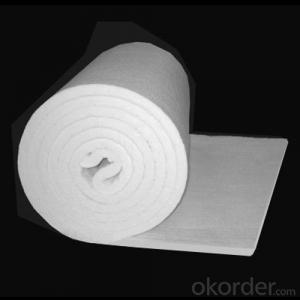

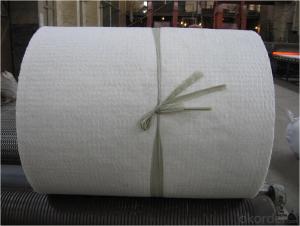

Ceramic Fiber Blanket for Petrochemical Industrial Insulation Images

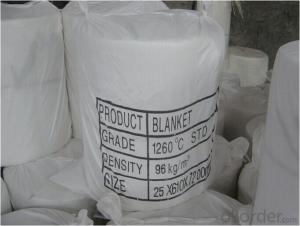

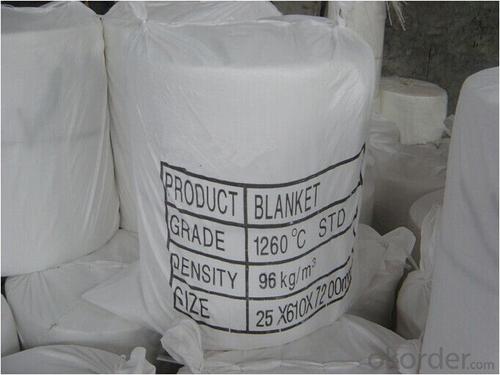

Ceramic Fiber Blanket for Petrochemical Industrial Insulation Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | ≤3 | ≤3 | ≤3.5 | ≤3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blankt for Petrochemical Industrial Insulation

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q: will eating extra special high fibre cereal with milk help to lose weight?

- i think of a clipless one works extra properits reported as a curling wandit varies from 20-40 5 $ reckoning on what you pick it to look likeyou probably choose one that is going from 1inc to a million/2 inchin case you pick those flowy curlesyou will come across those at a harmones or any form of elegance shop generally.

- Q: I'm a female 5'2 about 116 lbs.My goal is to have a flat stomach and tone the rest of my body.I'm working out 5 times a week (cardio) and I'm afraid that I might lose weight all overMeaning that I might lose the little that I havelolSo the question is how can I obtain a flat stomach while lifting up my butt and toning my legs?Should I drink protein shakes? Or will that case me to gain more weight on my stomach?Thanks )

- Dark out shade and black out curtains u can buy cheap color cardboard by the kids markers in target fix great on the window or a cheap way like I do take an extra sheet use push pins around the window then put up your curtains so u can hide the sheet

- Q: I am trying to knit a pair of socks for the first time and I started knitting a gauge thing tonightIt looks like it is going to turn out to be 10 stitches per inch which seems like a ton to meI'm using Knit Picks Essential yarn and size 2 needlesDoes this sound right?

- Well, even for a size 2 needle you're a little on the tight side, but for socks, that's what you want and Essentials is supposed to handle itThe better question is, does the fabric feel too stiff to you? People are right, socks knit on sock or fingering/baby weight yarn on size 0 - 3 needles should show a gauge of 12 - 7 stitches per inch.

- Q: i'm installing crown moulding (maybe) around my roof eavesthere will only be about 6quot; of overhang, all enclosed by the crowni have plenty of upper attic ventilation (4 gable vents, 2 whirly birds), but how do i get my lower attic ventilation? no chance for bird blocking, so what is usually done in this case?

- You would need to live in an area that has many race horses and a track that is open year roundYou would also need to get on the good side of the influential veternariansVery, very few owners of the horses who get massage will trust their prize animals to just anyoneHorses don't line up at a massage table like cruise ship passengers so doing 6 horses per day is unrealisticThe better Equine Massage Therapist will charge up to $300 per session but may only do one or two horses per day and only 5 - 6 per week depending on the area and situation of the animal.

- Q: ok my house is always coldwe did the windows,doors, and have plenty of insulation in the atticbut the basement is unfinishedso i was looking for the best option for the basement ceiling/main level floori heard insulation,a reflective bubble type insulation or a drop ceilingare any of these the way to go is is there a better way.

- The classic chocolate truffle starts with chocolate and creamOne pint of cream to two bags 12 ounces each of semi-sweet or milk chocolate chipsBring cream to a simmer a few bubbles lazily popping up on the surface of the creamRemove from the burner and add chocolate chipsStir! until smoothAdd flavoring such as vanill or almond extract may be peppermintAllow this mass to cool until it is fairly solidPutting it in the fridge speeds this processScoop balls with a mini scooper or use a spoon to get a portion outShape into a ball roll in cocoa powder( In France they use unsweetened cocoa)Or allow to cool and melt some more chocolate chips carefully so it doesn't burnThe microwave or a double boiler is best for this and dip the truffle centers place on a wire rack over wax paper or a baking pan and allow to drip and then store in fridge after they've cooledThose little paper candy cups are nice they keep them separate.

- Q: We are replacing the carpet in our living roomI would like help in knowing what questions to ask to get good carpet but not more than we needI also want to be able to compare prices at several businessesWhat are the major factors to look for in carpet?

- Yes, you can use the crochet thread but it will not be as soft as fingering yarn Did you look at the baby yarns? all these are fingering weight! And because it is a scarf, you can use sports weight too if you wishScarves do not need to fit exactlyI like Caron and Red Heart yarns, have found a new one that I like just as well as those 2 but haven't looked for their fingering or sports weight yarns yet! Name is I Love This Yarn and is found at Hobby Lobby.

- Q: my kitten is 5 months oldhe loves to eat dirt(not grass) and will lick the concrete for 15 to 20 minutes at a timeDoes any one no what is going on??????HELP

- In my opinion, it is not a natural combination to put chocolate bits together with buttermilk biscuitsIf you think you would enjoy chocolate chunks with biscuits, then you should try it.

- Q: Sorry this might be longHi i'm sixteen years old and have always being in good healthLast month I went to peru and got a stomach virus which resulted in severe diarrhea, so i took cipro and it eventually cleared in three daysBut ever since this i've experienced nausea that was bad for two weeks and I still feel itAlso i feel this sensation of a lump in my throat nowadays.I had a stool sample and it turned out to be negativeI went to the doctor and he has given me zantac because he thinks it might be acid refluxThe zantac has not worked at all and it's been two weeksI'm starting to worry because I've never felt like this before and school started again so its hard for me to concentrate while I feel badMy mom thinks its all in my head but I still feel these symptomsShould I go see the doctor again? Any suggestions

- Go to to the foodnetwork site, they have plenty of easy recipes for chicken and some recipes have videos.

- Q: I have $70which ones are better? i have short think hair, and I need an iron that wont burn, and break my hairany sugustions? I also have to get some type of something that you put in your hair before you blow dry and straighten my hair? ??? Help!

- basically field mice can climb stems of plant life and sticks, yet a chew of yarn is: a million) too skinny, 2) temptable to chew onit fairly is fantastic for them to consume it, do exactly no longer make that their basically weight loss planplaced a carrot in for them to chew to ware their tooth downin the event that they do no longer ware their tooth down, (it fairly is scientifically shown) their tooth will strengthen with the aid of their techniques (i'm no longer basically saying that, it fairly is definitely shown.)

Send your message to us

Ceramic Fiber Blanket for Petrochemical Industrial Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords