Casting Iron Concrete Manhole Cover with OEM Service B125

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

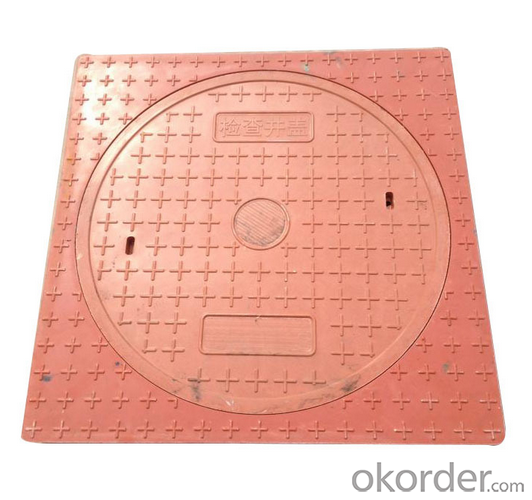

Material: Cast(Grey) Iron (GG 20, GG 25) and Ductile(SG) Iron(GGG 50).

Sizes: 300 mm X 300 mm (11.81" X 11.81") clear opening to 1200 mm X 1200 mm (47.2" X 47.2") clear opening.

Load Rating: A15, B125, C250, D400, E600 and F900

Painting: Black Bitumen, Epoxy and other paint as per provided by customers.

Other Features: Hinging, Locking provision available, Leak proof and customized designed available.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

4.Competitive price

The price of compound manhole cover is lower than stipulated standard cast iron ones.

5.Save mine resource

It is made by regenerated resin or regenerated plastic raw material, which save application of cast iron.

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: How to distinguish the forging parts and casting parts accurately

- To distinguish from the use of materialsForging materials are mainly made of carbon steel and alloy steel of various components, followed by aluminum, magnesium, titanium, copper and their alloys. The original state of the material is rod, ingot, metal powder and liquid metal. The materials needed for casting are mostly metal, wood, fuel, molding materials and so on. In contrast, the forging parts rarely produce dust, harmful gas and noise, etc., and play a more obvious role in environmental protection. Of course, because of this, the price of forged parts on the market is higher than that of castings.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

Send your message to us

Casting Iron Concrete Manhole Cover with OEM Service B125

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords