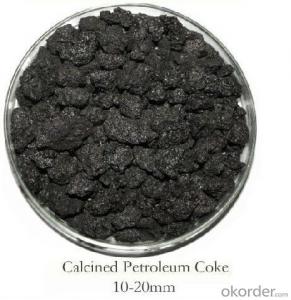

Carbon Additive FC 97 for casting iron and steel plant foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 300000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of carburant:

- Carburant for casting professional manufacturer in china 15 years experience;

- Carburant for casting specification as follows:

Item No (max) | Fixed Carbon | Sulfur(max) | Ash(max) | V.M | Moisture | Grain size(90%) | Nitrogen(max) |

CA-02 | 98.50% | 0.50% | 0.80% | 0.80% | 0.50% | 1-5MM | N/A |

CA-06 | 99.00% | 0.30% | 0.50% | 0.50% | 0.50% | 1-5MM | 1000divdivM |

CA-10 | 95.00% | 0.30% | 3.50% | 1.50% | 0.50% | 1-4MM | 700divdivM |

CA-12 | 80.00% | 0.10% | 16.50% | 3.50% | 2.00% | 1-5mm | N/A |

By using the carbon additive from CNBM in producing casting, it can increase the used quantity of Scrap steel and reduce the quantity of Scrap iron, or use no Scrap iron at all, CNBM carbon additive has follows properties: high absorptive character, no residue will be left, save production cost.

- Usage used to improve the Carbon content in steel-melting and Ductile iron foundry

- Characteristica high carbon, low sulfur, with stable effect for improving the carbon content, high absorptivity of carbon.

- Apply Used in electric furnace steel smelting and cast-iron for improving the carbon content

- Grain size normal size0.3-3mm 1-4mm1-3mm3-5mm,3-8mm,5-10mm or per as customers special requirement.

- Q: When will amines be fertilized?

- Rain does not applyAttention should be paid to the following problems in the application of ammonium bicarbonate:(1) ammonium bicarbonate can not be mixed with alkaline fertilizer in order to prevent ammonia volatilization and cause nitrogen losses.(2) to achieve the "five not": that is not mixed with fine soil without nitrogen, and there was dew without nitrogen, rain without nitrogen, Tian no inch of water without nitrogen, the sun does not apply. If fertilization time was sufficient, it is best able to make deep application of ammonium bicarbonate fertilizer or fertilizer ball. In addition, ammonium bicarbonate in transportation and storage, light light, close packed, stored in a cool dry place, not with the basic fertilizer and human excrement mixed, so as to avoid loss of effective fertilizer.(3) do not contact crops, seeds, roots, stems and leaves, so as not to burn the plants.(4) do not do fertilizer, otherwise it may affect the germination of seeds.(5): bogey and mixed fertilizer after application of ammonium bicarbonate will release ammonia, fertilizer and fertilizer will make contact, bacteria in the death of the fertilizer losing effect.(6) avoid spraying: spraying ammonium bicarbonate are easy to be burnt leaf, affecting crop photosynthesis

- Q: How does deforestation contribute to carbon dioxide levels in the atmosphere?

- Deforestation contributes to carbon dioxide levels in the atmosphere primarily through the release of stored carbon in trees and vegetation. When forests are cut down or burned, the carbon stored in their biomass is released as carbon dioxide, a greenhouse gas. Additionally, trees play a crucial role in absorbing carbon dioxide during photosynthesis, so their removal reduces the capacity to remove this greenhouse gas from the atmosphere. Therefore, deforestation not only releases carbon dioxide but also diminishes the natural carbon sinks, leading to an overall increase in carbon dioxide levels in the atmosphere.

- Q: How can individuals reduce their carbon footprint?

- Individuals can reduce their carbon footprint by adopting sustainable lifestyle choices such as conserving energy, using public transportation or carpooling, eating a plant-based diet, reducing waste, and supporting renewable energy sources. Additionally, individuals can also make a difference by planting trees, supporting eco-friendly products, and spreading awareness about climate change.

- Q: What is carbon offsetting in the automotive industry?

- Carbon offsetting in the automotive industry refers to the practice of compensating for the greenhouse gas emissions produced by vehicles through various methods. As automobiles are a significant contributor to carbon dioxide emissions, carbon offsetting aims to neutralize or reduce the overall impact on the environment. There are several ways in which carbon offsetting can be achieved in the automotive industry. One common method is through the purchase of carbon credits or offsets. These credits represent a reduction or removal of carbon dioxide emissions elsewhere, such as in renewable energy projects or reforestation initiatives. By buying these credits, automotive companies or individuals can offset the emissions produced by their vehicles, effectively balancing out their carbon footprint. Another approach to carbon offsetting involves investing in clean technologies and practices within the automotive sector. This can include the development and implementation of more fuel-efficient engines, hybrid or electric vehicles, or the use of alternative fuels. By reducing the amount of carbon dioxide emitted per kilometer driven, automotive companies can offset their overall emissions and contribute to a greener transportation industry. Additionally, companies in the automotive industry can engage in carbon offsetting by promoting sustainable practices throughout their supply chain. This includes working with suppliers to reduce emissions from the production of vehicle components or implementing energy-efficient manufacturing processes. By addressing emissions throughout the entire lifecycle of a vehicle, from production to disposal, carbon offsetting becomes a comprehensive approach to mitigating the environmental impact of the automotive industry. In conclusion, carbon offsetting in the automotive industry refers to the strategies and actions taken to compensate for the greenhouse gas emissions produced by vehicles. Whether through purchasing carbon credits, investing in clean technologies, or promoting sustainable practices, carbon offsetting aims to reduce the overall impact of automobiles on the environment and contribute to a more sustainable future.

- Q: What are the properties of carbon-based ceramics?

- Carbon-based ceramics, also known as carbon ceramics, are a unique class of materials with a combination of properties that make them highly desirable for various applications. These properties include: 1. High temperature resistance: Carbon-based ceramics exhibit exceptional thermal stability, allowing them to withstand extremely high temperatures without undergoing significant degradation or structural changes. This property makes them ideal for use in high-temperature environments such as aerospace components, brake systems, and heat shields. 2. Low density: Carbon ceramics are characterized by their low density, which contributes to their lightweight nature. This property is advantageous in applications where weight reduction is critical, such as in the automotive and aerospace industries, as it can enhance fuel efficiency and improve overall performance. 3. High hardness and wear resistance: Carbon-based ceramics possess exceptional hardness and wear resistance, making them highly durable and capable of withstanding abrasive forces. This property makes them suitable for use in cutting tools, bearings, and other applications where resistance to wear and erosion is required. 4. Excellent chemical resistance: Carbon ceramics are known for their excellent chemical resistance, which allows them to resist corrosion and degradation when exposed to various aggressive chemical environments. This property makes them valuable in chemical processing, semiconductor manufacturing, and other industries where resistance to chemical attack is crucial. 5. Good electrical conductivity: Unlike traditional ceramics, carbon-based ceramics exhibit good electrical conductivity due to the presence of carbon in their composition. This property makes them useful in applications that require both thermal insulation and electrical conductivity, such as heating elements, electrodes, and electronic components. 6. Tailorable properties: Carbon ceramics offer the advantage of being able to tailor their properties to specific requirements by varying the composition and processing methods. By adjusting factors such as carbon content, porosity, and microstructure, the mechanical, thermal, and electrical properties of carbon ceramics can be customized to meet specific application needs. In summary, carbon-based ceramics possess a unique combination of properties, including high temperature resistance, low density, high hardness, excellent chemical resistance, good electrical conductivity, and the ability to tailor their properties. These properties make them valuable materials in a wide range of industries, including aerospace, automotive, chemical processing, and electronics.

- Q: How does carbon impact the stability of tundra ecosystems?

- The stability of tundra ecosystems is impacted by carbon in several ways. To begin with, carbon is essential for the formation and development of tundra soils. When plants in the tundra grow and undergo photosynthesis, they absorb carbon dioxide from the atmosphere and convert it into organic matter. This organic matter eventually decomposes, adding carbon to the soil and creating a layer of permafrost rich in organic material. This layer of permafrost helps to stabilize the ecosystem. Furthermore, carbon in the form of vegetation acts as a protective layer against erosion in tundra ecosystems. The dense cover of mosses, lichens, and shrubs holds the soil in place, preventing it from being washed away by wind or water. This stabilization is crucial in the tundra, where plant growth and soil development are limited by cold temperatures and short growing seasons. Moreover, the stability of tundra ecosystems is influenced by the release of greenhouse gases, such as carbon dioxide and methane, from the melting permafrost. As global temperatures rise, the permafrost thaws and releases stored carbon into the atmosphere. This process creates a feedback loop, as the released carbon contributes to further warming, which accelerates permafrost thawing. This feedback loop has the potential to disrupt tundra ecosystems by altering the balance of plant and animal life, disrupting nutrient cycling, and increasing the risk of wildfires. In conclusion, carbon plays a vital role in maintaining the stability of tundra ecosystems by contributing to soil formation, preventing erosion, and regulating greenhouse gas emissions. It is crucial to understand and manage carbon dynamics in the tundra in order to preserve these unique and delicate ecosystems in the face of climate change.

- Q: How does carbon impact the formation of smog?

- Carbon plays a significant role in the formation of smog, particularly in the form of carbon monoxide (CO) and volatile organic compounds (VOCs). When fossil fuels are burned, such as in vehicle engines or power plants, they release carbon monoxide into the atmosphere. Carbon monoxide is a colorless and odorless gas that can react with other pollutants in the presence of sunlight to form ground-level ozone, a key component of smog. Furthermore, carbon-based compounds known as volatile organic compounds (VOCs) are also emitted from various sources, including industrial processes, gasoline vapors, and chemical solvents. These VOCs can undergo chemical reactions in the presence of nitrogen oxides and sunlight to create ground-level ozone as well. Both carbon monoxide and VOCs contribute to the formation of smog by reacting with nitrogen oxides (NOx) in the presence of sunlight. This chemical reaction forms ground-level ozone, which is a primary component of smog. Ozone is harmful to human health and the environment, and its formation is exacerbated by the presence of carbon emissions. Reducing carbon emissions is crucial to mitigating the formation of smog. Transitioning to cleaner and more sustainable sources of energy, such as renewable energy, can help decrease the amount of carbon released into the atmosphere. Additionally, implementing stricter emissions standards for vehicles and industrial processes can also contribute to reducing carbon emissions and consequently limit the formation of smog.

- Q: How is carbon used in the water treatment process?

- Carbon is used in the water treatment process in a variety of ways. One common method is through the use of activated carbon, which is highly porous and has a large surface area. This allows it to effectively adsorb and remove impurities from water. Activated carbon is often used in the form of granules, pellets, or blocks in water treatment facilities. It can be added to the water during different stages of the treatment process. For example, during the initial filtration stage, activated carbon can be used to remove particles, such as sediment and chlorine byproducts, that can affect the taste and smell of the water. Additionally, activated carbon is effective in removing organic compounds, such as pesticides, herbicides, and industrial chemicals, that may be present in the water. These compounds can be harmful to human health if consumed, so the use of activated carbon helps to ensure the water is safe for drinking. Another way carbon is used in water treatment is through the process of carbonation. This involves the injection of carbon dioxide gas into the water, which helps to lower its pH level. Carbonation is often used in the treatment of alkaline water sources, as it helps to neutralize the water and make it more suitable for consumption. Overall, carbon plays a crucial role in the water treatment process by effectively removing impurities and improving the quality of drinking water. Its adsorption capabilities make it a valuable tool in ensuring that water is safe and healthy for consumption.

- Q: What do you mean by carbon fiber for 1K, 3K, 6K and 12K?

- Upstairs copy so much, people watching tired not tired.1K, 3K, 6K, 12K refers to the carbon fiber yarn containing the number of filaments, K is unit (thousand), 1K is 1000 followed, 3K is 3000, and so on, and so on!

- Q: What are the different types of carbon-based concrete additives?

- Concrete can be enhanced and improved by incorporating various types of carbon-based additives. These additives, derived primarily from carbon-based materials, can be categorized into three main types: carbon nanotubes, graphene, and carbon fibers. 1. Carbon Nanotubes: These cylindrical structures consist of carbon atoms arranged in a distinct hexagonal pattern. They possess exceptional mechanical and electrical properties, making them highly sought-after as concrete additives. By adding carbon nanotubes to concrete, its strength, durability, and toughness can be improved. Additionally, these nanotubes enhance the electrical conductivity of concrete, which proves advantageous for applications such as self-healing concrete and anti-static flooring. 2. Graphene: Graphene is a two-dimensional lattice composed of a single layer of carbon atoms. It is renowned for its remarkable strength, high electrical conductivity, and excellent barrier properties. When incorporated into concrete, graphene significantly enhances its mechanical properties, including compressive strength, flexural strength, and resistance to abrasion. It also improves the durability and impermeability of concrete, providing resistance against water and chemical penetration. 3. Carbon Fibers: Carbon fibers are elongated and slender strands derived from organic polymers like polyacrylonitrile or pitch. They possess exceptional tensile strength and are commonly used as reinforcements in various construction materials, including concrete. The addition of carbon fibers to concrete enhances its flexural strength, resistance to impacts, and behavior when subjected to cracks. Furthermore, carbon fibers improve the ductility and toughness of concrete, making it more resistant to dynamic loads. It is important to note that each type of carbon-based concrete additive offers unique advantages and applications. Carbon nanotubes provide exceptional mechanical and electrical properties, graphene enhances strength and barrier properties, while carbon fibers strengthen flexural strength and impact resistance. The choice of additive depends on the specific requirements of the concrete application and the desired performance characteristics.

Send your message to us

Carbon Additive FC 97 for casting iron and steel plant foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 300000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords