Calcium Silicate Board with Long Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Board with Long Fiber

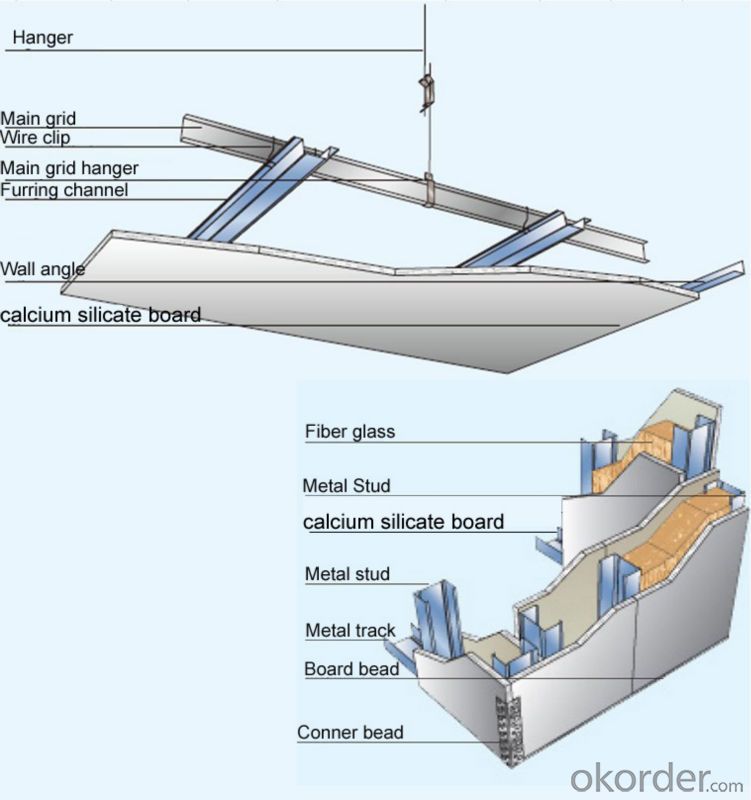

Asbestos-free Boards Calcium Silicate also known as the porous calcium silicate board, is a fiber-reinforced calcium silicate board, with silicon oxide, calcium oxide, and the reinforcing fibers as the main raw materials, made through mixing, heating, gelling, molding, autoclaving and drying processes. Calcium silicate board is a new type of rigid insulation material.

The calcium silicate board products, also called asbestos free mipor calcium silicate products, are mainly used in industries like power, oil, chemical, shipping, metallurgy, light to provide thermal insulation on industrial pipelines and thermal equipment to decrease heat loss, lower cooling effect on medium and delay its condensation during production, meanwhile save energy, improve work efficiency, lower the temperature at work area, improve working condition, avoid scald among workers.

The calcium silicate board can be specifically used as thermal insulation layer of power plant boiler and turbine body, chemical plant cracking furnace and distillation column, steel plant heating furnace, drying oven, paper mill digesting kettle, also the thermal cover on the pipelines in these plants.

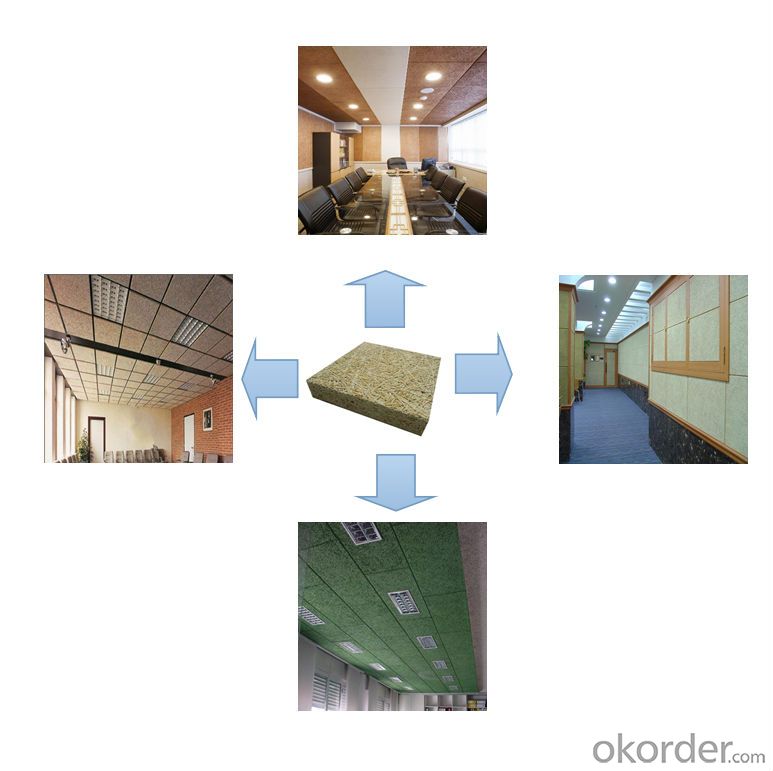

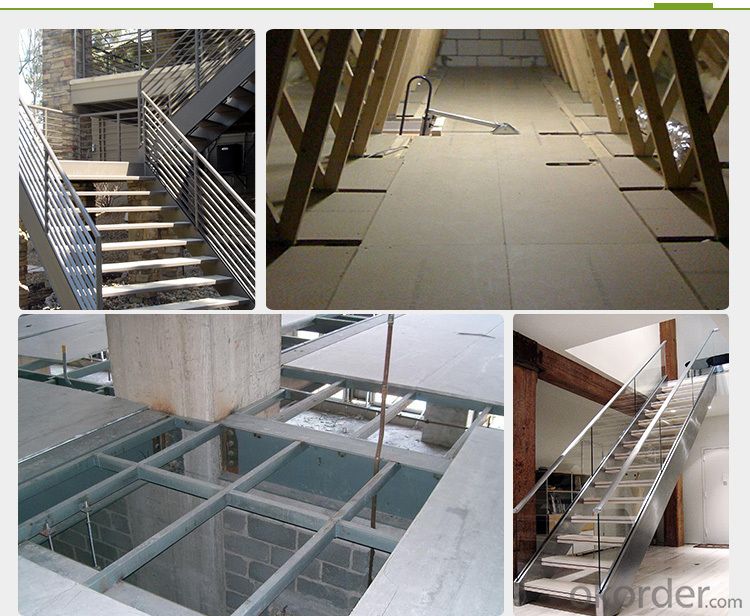

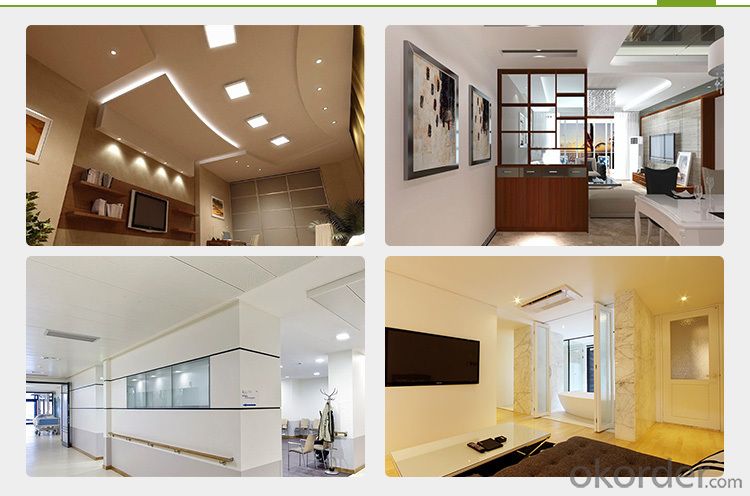

Product Applications:

Calcium Silicate Board are ideal for use in the below applications

Supermarket, marketplace

Underground, air port, bus station

Hall, corridor and toilet

Hotel, restaurant, kitchen

School, office, meeting room ,hospital etc

Product Advantages:

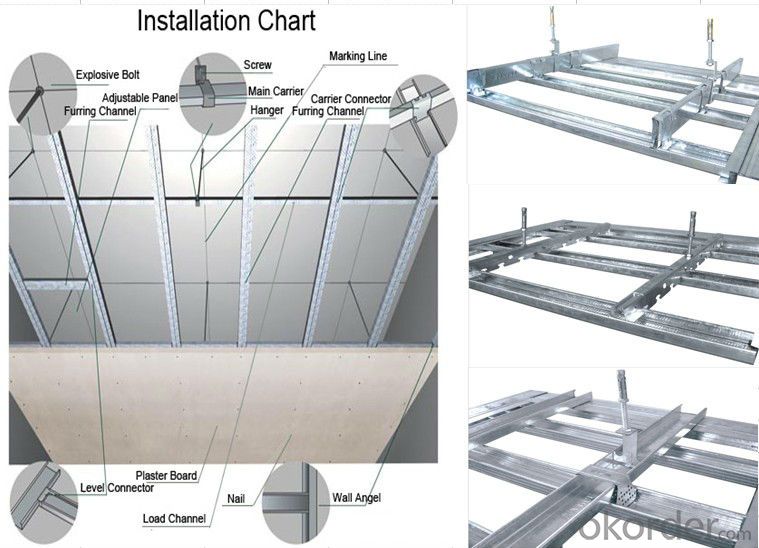

Good durability and can withstand high-temperature limit of the continuous thermal load

Low thermal conductivity,in the whole scope of use is unmatched within the adiabatic Performance

Light weight,high stength,its strength is rigid insulation products in the highest

Durability,long-term use of ceramic fiber felt no similar powder

Construction practical,with ordinary tools can be arbitrarily cutting products

Used safety,hygiene,asbestos-free,sulfur,chlorine such poisonous substances

Main Product Features:

Great soft bulk with elastic.

High strength

The strongest refractory materials among the inorganic thermal materials with similar density

Heat resistance:

Non-deformation within the working temperature range

Thermal insulation:

Lower thermal conductivity compared with other massive hard refractory materials

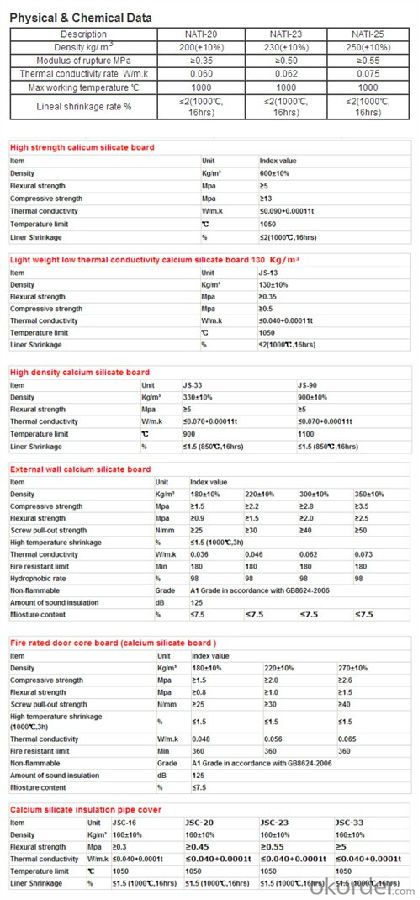

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab crack (crack was autoclaved late cooling stage, it refers to the irregular surface crack, calcium silicate board, or bright or dark is likely to cause fracture, calcium silicate board, low strength, appearance and performance is not up to the requirements)The main reason for the crack is to cool down too quickly.Solution: control the cooling rate, slow exhaust steam.The above is the calcium silicate board equipment in the production of prone to stick, blank, cracks and other phenomena of the reasons and solutions, if you encountered similar problems in production, you can have some reference.

- Q: What are the three major effects of fly ash in concrete?

- Fly ash "micro aggregate effect" in the fly ash particle size is very small beads and debris in cement can be the equivalent of unhydrated cement grains, tiny beads equivalent to nano material and lively, can significantly improve and enhance the structural strength of concrete and improve the homogeneity of products, and compactness.

- Q: Cement is not silicate products

- There are different kinds of cement: silicate series, aluminate series, sulphoaluminate series, sulfur ferrite system, etc.

- Q: What's the use of white portland cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- The current power plant thermal insulation is mainly carried out by use of various types of insulation materials, thermal insulation materials commonly used include calcium silicate products, pipes, rock and aluminum silicate fiber products, due to their different properties are applicable to different environments. The equipment with temperature at 300-600 DEG C often adopts aluminium silicate products and calcium silicate products to compound heat preservation. While the temperature is less than 300 degrees, the mineral wool products are usually used for thermal insulation.

- Q: What's the difference between white cement and ordinary cement?

- The typical feature of white cement is high whiteness, with bright color, generally used for a variety of architectural decoration materials, painting, sculpture, a typical floor, terrazzo, white cement can be used to produce white and colored concrete, is the largest cement production decoration.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: How to make building glue?

- A building adhesive consisting of 28-50wt% sodium silicate aqueous solution, 34-53wt% quartz sand, and 8-35wt% magnesium silicate. The product of the invention can be used for the bonding of ceramic tile, floor tile, marble, wood and glass in indoor and outdoor decoration of buildings. It can be used as a substitute for cement in the field of tiling. The product of the invention is environment-friendly products without pollution when being produced and used. The utility model has the advantages of low price, strong adhesive force and curing at normal temperature.

- Q: What is a building energy-saving materials?

- Heat insulation materials and insulation materials collectively referred to as thermal insulation materials.The commonly used thermal insulation material: mineral wool, rock wool, glass wool (in rock, slag as the main raw material, by high temperature melting, made by centrifugal methods such as cotton and thermosetting resin binder insulation products. ) foam plastics and porous polymers, expanded perlite and their products, calcium silicate insulation products, all kinds of composite insulation materials.

Send your message to us

Calcium Silicate Board with Long Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches