Raw Materials for Refractory - Calcined Alumina Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcined Alumina Powder for Refractory Use

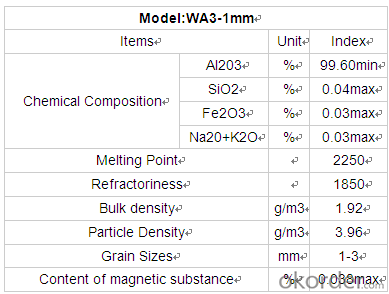

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application:

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

aluminum oxide property:

The product is white powder,uniform of particle size,easy to dispersion,stable of chemical performance,moderate in high temperature shrinkage and excellent sintering properties.

The product is the basic raw material in the production of heat-resisting product,abrasion-resisting products and decay resistance products such as for producing the high alumina refractories, high-strength ceramics, automobile spark plugs and high-grade abrasive materials.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: what's the standard of fireproofing material?

- Class A1 is divided according to the combustion performance of GB8624-2006 building materials and products. Specific technical index requirements are: 1, the temperature rise ≤30 degrees;mass loss rate ≤50%; combustion duration time is 0; 2, main components, overall products, gross calorific value of external secondary components ≤2.0MJ/kg; any inner secondary component ≤1.4MJ/kg; (there are difference between homogeneous and non-homogeneous). Z802 building materials noninflammability testing furnace has to be used for testing technical indicators mentioned in test 1, using Z805 building materials combustion heat value to test technical indicators mentioned in test device 2.

- Q: What is unshaped refractory?

- Concrete。 Early concrete technology appears, it is not forming products in the heat furnace, some parts such as pit heating furnace furnace wall, rotary kiln mouth ring, cutting slope and discharge chamber wall, etc., are able to design large masonry (top heating block weighing 3-4 tons) made concrete. Concrete cattle production method is to pour the material into the model, vibration molding, after the release of heat treatment, to provide users in addition to large blocks, weight, in use, and machine pressure brick no essential difference. The amount of water used in the casting material produced by the manufacturer is less than 10% above that in the field, and the processing quality is good and the quality is stable. As the bricks are large and heavy, the site shall have lifting equipment. As long as the site can be hoisted, the concrete shall be used as far as possible, or smaller ones, and some people can lift it. Concrete does not require the user to do a special heat treatment, this point is very meaningful.

- Q: How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q: Does anyone know which materials belong to light fire resistant material?

- Fire partitions can be divided into organic and inorganic fire partitions, the main ingredient of organic fire partitions is organic material, which can be used for cable tray with corrosion-resistant and fire protection requirements, and the main ingredient of inorganic fire partitions is inorganic material, mainly used for fire protection. As the main component is inorganic material, it can not be use in projects with acid-resistant and alkali-resistant requirements. Of course, the price of the same amount of organic fire partitions is generally more expensive than that of the inorganic fire partitions . The fire endurance of these two products of general enterprises are 3 hours.

- Q: I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- fireproofing glass is mainly control the spread of fire or smoke insulation, and is a measurable fireproofing material, the fireproofing effect is evaluated by the fire resistance. It is through a special process and treatment, and it is a special glass which can maintain its integrity and thermal insulation in the specified fire resistance test. Original glass of fireproofing glass can be used float flat glass, and composite fireproofing glass also can use monolithic fireproofing glass.

- Q: What are the commonly used fire protection materials

- Firewall. The fire wall is made of non combustible material, and is directly installed on the base of the building or the reinforced concrete frame or fire proof walls . Fireproof limit of the firewall, according to the current "building regulations", is 4 hours, wheras the specification of Technical specification for concrete structures of tall building is 3 hours. doors resistant to fire, heat in a certain period of time These door usually prevent the spread of fire and gas in the fire resistant wall, staircase, pipe well. Fire door can be divided into steel fire doors, wood fire doors and composite materials fire door according to the material used. According to the limit of fire resistance can be divided into the class A fire door (1.2h), B fire doors (0.9), class C fire door (0.6h); (3) fire window. Windows resistant to fire, heat in a certain period of time It is usually installed in the fire resistance wall or doors; the fire shutter. This roller shutter can be refractory in a certain period of time. It is typically used for heat and fire insulation in escalator with difficulties to install fire resistant wall, fire resistant valve and smoke resistant valve. Fire resistant valve is installed in the ventilation and air conditioning system of air supply and return air duct, usually in the open state, fire, It will be turn off when the pipeline gas temperature reached 70 degrees, can meet the requirement for fire resistance and insulation for gas and fire. Smoke fire resistant damper installed in the exhaust system pipe, when the pipeline gas temperature reached 280 degrees, it will close automatically, insulating fire and gas.

- Q: what's the detailed address of fireproof and thermal inuslation matertial market?

- following are the detailed address of fireproof and thermal inuslation matertial market: Central China Building decoration materials market,Hanxi 1 road No 95, Xinyongan Tangcai decoration material makert, Jianghan district Tangcai road No 53, Baoye decoration material wholesale market, Wuhan Wuchang district Minzhu road No 620.

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q: what textures of furnace refractories are good?

- First, it depends on the kiln. If it is the cubic kiln, the top and the wall portion should use alumina hollow ball bricks. The bent seal and kiln car use heavy corundum bricks. If it is the consecutive kiln, the burning zone shall all use the alumina hollow ball bricks, and both the burning zone bent seal and the brick kiln car bent seal use the heavy corundum bricks. Ifit is the pit furnace, furnace walls and roof use the alumina hollow ball bricks, and the bottom of the furnace use heavy corundum bricks.

- Q: Classification of porosities in refractories and their effects on properties

- Effect of apparent porosity on properties:The porosity is high, the volume density is low, the structure become more loose, generally low strength, corrosion resistance worse (slag infiltration and erosion along the hole toward the inside), but to improve the thermal shock resistance (resistance to thermal shock and not damaged).

Send your message to us

Raw Materials for Refractory - Calcined Alumina Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords