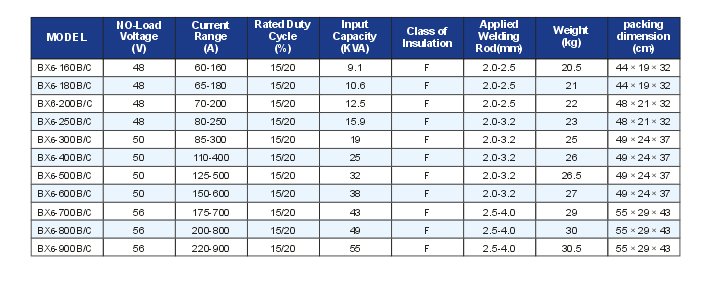

BX6-B Series AC ARC Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Top type transformer, step current adjustment fan cooling, high efficiency and safety

Compact, light, portable suitable for

Instruction of BX6-B Series AC Arc Welder

Top type transformer, step current adjustment fan cooling, high efficiency and safety

Compact, light, portable suitable for home and small factory

We have two kinds of welder, one is aluminium, one is copper

- Q: What gas does argon arc welding machine use?

- Argon arc welding machine must be argon, and there may be a mixture of gas. Sales of welding equipment in Shenzhen

- Q: What is the difference between argon arc welding machine and welding machine?

- The argon arc welding machine has a set of high frequency arc striking device which can smoothly ignite the arc and an electromagnetic valve, which is used to control the delay closing of argon. Everything else is the same. Argon arc welding machine may also be AC DC is mainly based on the different welding set.

- Q: (reallink authentic) inverter DC TIG / arc welder WS-300A how to use the reallink dual-purpose welding?

- The red knob is a current size adjustment, is a function of manual welding when thrust regulation (welding current welding at large strengthening efforts) switch alone know how to use it?

- Q: Shanghai Dayang WSE5-315 wsem and Shenzhen Jiashi of square wave AC DC inverter argon arc welding of WSE315, the function is the same? Can it be completely replaced? If welding, auto cylinder and cylinder head can be used? Why is the former heavy 195KG and the latter only 38KG?

- Ask I think welding non-ferrous metals 315 small.

- Q: How to maintain the Panasonic inverter DC TIG welder in Japan?

- If TSP or WP do not need how special maintenance, very resistant to use, see used for more than 10 years, which filled with dust can still use. Inverter welding machine argon arc welding machine is also very resistant to use, pay attention to see the sustained load rate, do not exceed the long-term use of norms on the line. It's rare to see Panasonic argon arc welding machine broken.

- Q: Who can tell me how the performance of WSE-200G Ruiling argon arc welding machine, welding aluminum welding is good? And what's the difference between the letter "G" and "P" after the model number? Thank you

- As the Christie WSE-200P welder performance. WSE-200P welding machine has pulse function, more suitable for welding aluminum.G welding machine manufacturer's product code. P pulse.

- Q: What's the difference between stainless steel cold welding machine and argon arc welding machine?

- There must be some differences, but they are all argon arc welding. But there are changes on the program board.

- Q: What does the 315 argon arc welder cool with water?

- Argon arc welding is a kind of welding technology using argon gas as protective gas. Also called argon gas shielded welding. That is, argon shielded gas is applied around the arc welding, and the air is separated from the welding zone to prevent the oxidation of the welding zone.

- Q: Can argon arc welding machine be welded directly with electrode?

- May not。Single function tungsten argon arc welding machine can not use welding rod arc welding function.The no-load voltage is higher than that of TIG welding. Because the arc welding is done by striking or striking short circuit, tungsten arc welding adopts high frequency arc starting and arc starting method is different. When the no-load voltage of TIG welding is too low, the welding rod arc welding can not be ignited at all, and the welding can not be discussed.Single tungsten inert gas arc welding, without welding joint, direct gas and electricity integration type TIG welding torch socket.

- Q: What is the cause of the no ignition in the DC argon arc welding machine?

- As you say, the machine should be all right! Here's a way. You can try: the tungsten electrode is close to the weldment, and the wire is rapidly crossed to make the weldment short circuited with the tungsten electrode in a very short time, which can well ignite the arc!! Have a try!

We enjoy good reputation at home and abroad. Our company specializes in manufacturing motors, pumps, air compressors, welders and cutters, etc.

We have enjoyed high favor among the customers. In addition, we can produce motors according to the request of the customers. At the same time, we supply complete inspection of electric property and mechanical property. Your coming and choosing our products will be sincerely welcomed. We will sincerely supply best services for you.

1. Manufacturer Overview

| Location | Zhejiang, China (Mainland) |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | North America3% .South America3% .Eastern Europe5% .Southeast Asia12% .Africa20% .Oceania1% Mid East30% .Eastern Asia5% .Western Europe5% .Central America3% .Northern Europe3% Southern Europe2% .South Asia8% |

| Company Certifications | Certificate of Conformity;Certificate of Conformity |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BX6-B Series AC ARC Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords