BUTTERFLY VALVE FLANGE DOUBLE ECCENTRIC DUCTILE IRON DN80- DN1200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Butterfly | Pressure: | Medium Pressure |

| Power: | Manual | Material: | Ductile Iron | Temperature of Media: | Medium Temperature |

| Media: | Water | Port Size: | DN80-1200 | Place of Origin: | China (Mainland) |

| Model Number: | D71 | Brand Name: | CNBM |

Packaging & Delivery

| Packaging Detail: | PLYWOOD OR WOODEN BOX |

| Delivery Detail: | 15--30 DAYS |

Specifications

1. Face to face is according to BS5155/DIN3202-F4/EN 593

2. Working pressure: PN10/PN16/PN25

Quick Details

Standard or Nonstandard: | Standard | Structure: | Eccentric | Pressure: | Medium |

Power: | Manual | Material: | Cast iron, Ductile iron | Temperature of Media: | Normal |

Media: | Water, Oil, Gas | Port Size: | DN80-DN1200 | Place of Origin: | China |

Brand Name: | CNBM | Certification: | ISO9000, CE,CCS,DNV,ABS,TS | ||

Packaging & Delivery

Packaging Detail: | Each Piece into one bubble plastic bag, several pcs into one Wooden crate or according to customers requirements |

Delivery Detail: | within 30 days |

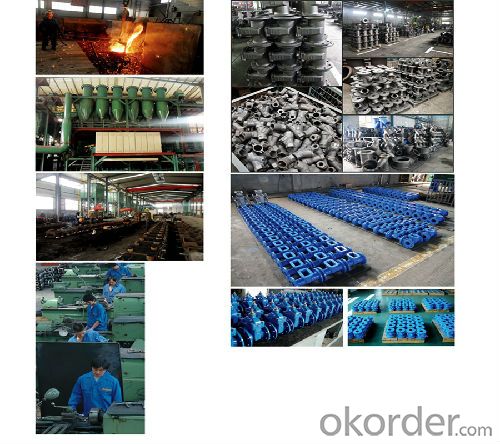

Our product features are as follows:

1. Newly developed facilities ensure high and stable quality.

2. Enable to supply UL/FM valves.

3. Experienced technology

4. Excellent after-sale service to satisfy customers.

5. Sufficient capacity ensures prompt delivery.

6. Continuous quality improvement and new designs development.

7. Reasonable and stable price

8. Meets different countries standards, such as ANSI,DIN,BS etc.

Working pressure:10Bar/16Bar/25Bar

Pressure Temperature Ratings | |

working pressure | 16bar/25bar |

testing pressure | shell:24bar/37.5bar |

seal:17.6bar/27.5bar | |

working temperature | -20 degree to 110 degree EPDM seat |

-10 degree to 80degree NBR seat | |

suitable media | Water, Oil& Gas. |

- Q: Butterfly valve D41W-1, 41, W, 1, respectively, what does that mean?

- This butterfly valve in our factory called butterfly, 4 represents the connection of the flange connection flange is French, 41 in 1 on behalf of butterfly valve, W represents the body seal, is C that is actually the correct type of cast steel, should be D41W-1C. Suitable for ventilation, smoke, and these media.

- Q: Okay, so I've been thinking about trying to learn how to play my dad's baritone bugle, but I have no idea how to. If anyone had a good fingering chart for it, that would be great. The bugle has one valve and a trigger. I am a natural flute player and percussionist, so this is my first time playing a brass instrument. Needless to say I am very confused. Call me a noob, I don't care, as long as you get me a fingering chart for a 1 valve baritone bugle. Please help. :)

- Baritone Bugle

- Q: Not the cold and hot water shut off valves. The one with a tiny handle and it looks like a T. what does it do? should I mess with it?

- Is the valve coming off a water supply line? if so, it's a needle valve probably installed at some point during a remodel or while adding an appliance. If it's on the cold side it will most likely go to a refrigerator ice maker or water dispenser, if it's on the hot side it may go to a dishwasher or other device that requires hot water.

- Q: What's the difference between a clip type turbine butterfly valve and a flanged turbine butterfly valve?

- The clamp and flange are the two connections.The clip type is cheaper and the price is approximately 2/3 of the flange.The length of the clip type valve bolt is longer, and the requirement of construction accuracy is higher. If the flange on both sides is wrong, the bolt will be subjected to greater shearing force, and the valve will leak easily.

- Q: How warm is the PTFE butterfly valve?

- The normal temperature can be kept at 120 degrees and the instant temperature is 150

- Q: How do hydraulic butterfly valves work?

- Butterfly valve hydraulic drive device working principle1. manual operationWhen the hydraulic system suddenly fails, the valve can not move when the butterfly plate at any stop. Then, shaking the manual device, the guide block guide block in front of the manual shaft together with the driving shaft end, the cogging and drive shaft spline manual corresponding to the slot. Then, by dialing the driving device, the dial is shifted to the left end, and the transmission spline is connected with the manual shaft by a gear sleeve (the driving device is provided with a limit for preventing the tooth sleeve from jumping up), and the crank is disengaged from the hydraulic cylinder to disengage the hydraulic cylinder. Then turn the manual device and use the manual device to realize the disc movement.2. hydraulic operationWhen the hydraulic system returns to normal operation, the actuating device needs to be operated by hand. First, adjust the hydraulic cylinder to its initial state (0 digits) or at any position. Then manually adjust the opening of the disc to the position corresponding to the cylinder stroke (by observing whether the mark on the gear sleeve is in accordance with the mark on the crank, and judge the position of the disc and the cylinder). Then pull the gear sleeve and engage the spline on the crank by poking the driving device. Then fix the shift to prevent jumping. At this point, start the hydraulic system to restore fluid flow.

- Q: what are the step i need to do so i can change the valve seals my truck has been smoky.,,, any websites i want todo it myself... 1989 chevy silverado 2500 350 engine 5.7L

- If it only puffs blue smoke when you start it and then burns off after a second then its the valve stem seals that need to be replaced which is common on 350 and 305 engine prior to 1990 and have over 150,000 miles or so. The Chilton repair manual explains the procedure on how to replace these.Now if it smokes all the time then it could be caused by worn out rings on your pistons .

- Q: Who was the first doctor to discover Pulmonary Valve Stenosis? Also, who was the first doctor to perform surgery for it? Please and thank you for your help.P.S. I have this condition.

- 1761 - Pulmonary valvar or valvular stenosis is one of the more common forms of congenital heart malformations and it has been extensively studied since the original description of pulmonary valve stenosis by John Baptist Morgagni in 1761. 1888 - Tetralogy of Fallot, first characterized by Dr.Etienne Fallot in 1888, is present in about 3000 children born each year in the United States. It is a combination of four heart abnormalities. Dodrill and his colleagues employed it with success for the open correction of a stenotic pulmonary valve in October 1952.

- Q: Butterfly valve D71X-16 and D71X-16Q what is the difference?

- The two difference is that the body of the material is not the same, 16 behind with no sign, expressed as a default, is carbon steel (usually C), if you need to specify material, just behind with symbols, such as Q nodular cast iron, stainless steel P.Butterfly valve refers to the closure of parts (valve or butterfly plate) as the disk, around the valve shaft to achieve rotation and closing of a valve, the main cut off on the pipe and throttling role. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve used in furnace, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection engineering system, conveying a variety of corrosive and non corrosive media pipeline, used to adjust and cut off the media flow. Butterfly valve categories are: handle butterfly valve, turbine butterfly valve, pneumatic butterfly valve, electric butterfly valve and so on.

- Q: Hey YA! I am looking at getting an 01 Honda Prelude this month and valve adjustment keeps coming up when people discuss this car and other cars as well. What is this? Does it cost a lot to do, and is it important? Thank you!

- Adjusting hydraulic lifters, also called setting the valve lash provides the necessary travel and operation for the opening and closing of the intake and exhaust valves. Most new vehicles use hydraulic lifters, since their operation and design provides an easy and simple method of keeping the valve train in synchronization. You can perform the adjustment with a cold, static engine or during engine idle once the operating temperature has been reached. Adjusting the lifters on a running engine, however, can present a problem with oil splashing upward from the tappets. They make a spring clip to prevent it from getting all over the engine and compartment. Cost vary from city to city Mechanic to mechanic Hope it helps Lr

Send your message to us

BUTTERFLY VALVE FLANGE DOUBLE ECCENTRIC DUCTILE IRON DN80- DN1200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords