Butterfly Valve DN750 BS5163 with Hand Wheel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

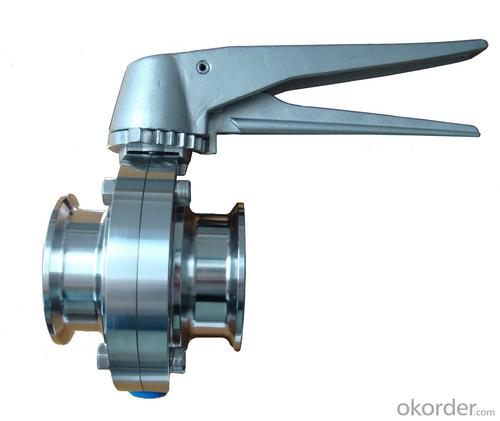

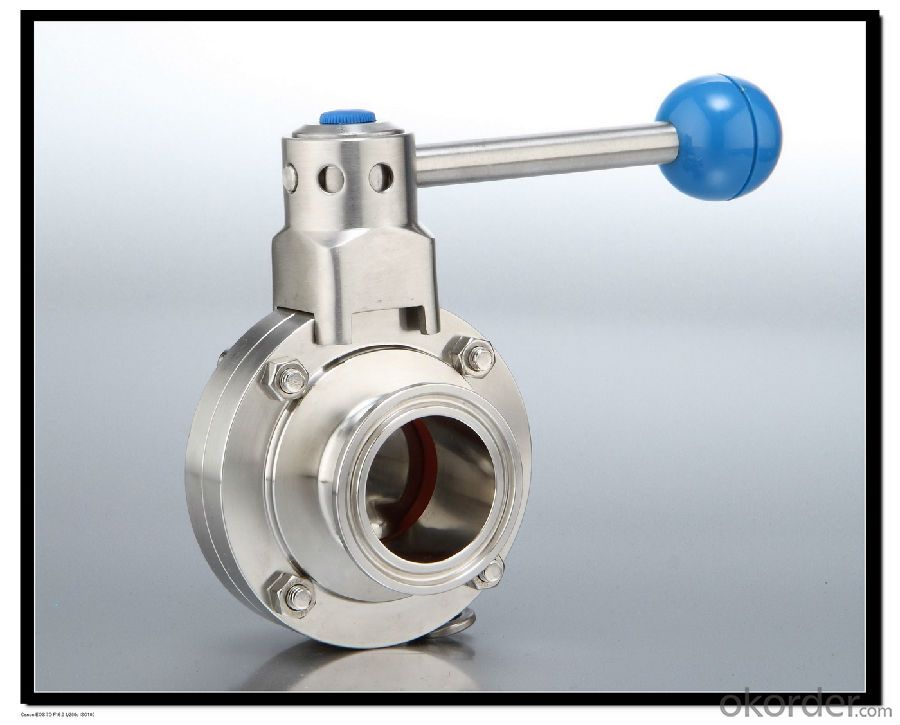

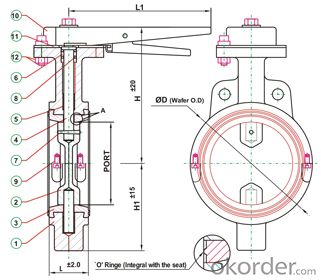

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

1)Size: DN40-DN1400

2)Material:body-CI/DI/WCB/SS

disc:DI/CF8/CF8M/C95400

3)Professional Maufacturer for more than 10 years

PRESENTATION:

1) Sizes:

DN40mm-DN1400mm

2) Materials:

a) Body: CI(cast iron ,GG25 )/ DI (ductile iron ,GGG40)

b) Disc: DI / CF8 / CF8M / C95400

c) Seat: EPDM / NBR / TEFLON / VITON

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Butterfly valve model D344H and D343 difference

- [1] D344H-10C DN400, D343H-10C DN400, to talk about the 2 types of butterfly valves in common: D on behalf of 3 Representatives is butterfly valve, turbine driven, 4 representative is in the middle of flange, representing 10 kg pressure, C is the representative of the valve material is cast steel, DN400 represents the valve diameter; say that there the difference of the 2 models, there is a place where there are differences, second means 4 of the first models is the new type sealing valve structure is variable eccentric, second of the second models of the 3 represents the structure of the valve is three eccentric, and three eccentric seal type variable eccentric in fact, is a meaning.Sealed three eccentric butterfly valve, sealed variable eccentric butterfly valve, corresponding to the central butterfly valve and sealed single eccentric butterfly valve.

- Q: How do you draw the butterfly valve in the engineering drawing?

- Butterfly valve there are many kinds of painting, according to the design institute out of the icon, below we together to understand the icon, which has the butterfly drawing.

- Q: How big is the butterfly valve with a diameter of 80?

- With the 80 caliber butterfly valve.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid.

- Q: How can I get the fire signal butterfly valve?

- At the input end of the input module, some resistors or terminals are added to the product

- Q: Butterfly valve D71X-10 and butterfly D371X-10 what is the difference?

- One more 3 in D71X-10 stands for adding a worm gear to the valve. What are the same, the difference is driven by the handle into the drive, gear drive, worm gear drive for large caliber butterfly valve a little less, because the valve torque is big, big, hard to handle and can rotate, and if the worm, you can turn a few laps handwheel. If there are other questions, we can continue to ask questions, the city butterfly valve manufacturers

- Q: Specifically an engine valve retainer.

- Valve Retainer

- Q: For example, the arrow above is from left to right, and the direction of my current is from right to left. Is that ok? I have a diameter of 700 of the hard seal butterfly valve is so installed, but it will leak water, it will not leak, very serious

- The direction of the arrow on the valve body refers to the direction of the medium.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q: Butterfly valve, two-way pressure and one-way pressure what is the difference?

- Popular, one point one pressure side, a double-sided pressure.

- Q: How to control the single acting pneumatic butterfly valve?

- Single acting pneumatic butterfly valve, Luoyang crown butterfly pneumatic butterfly valve, mainly divided into two types of normally open and normally closed. What kind of effect do you want to achieve?

- Q: When i waa replacing the valves in the las 4 valves , they dropped and i dont know how to make them go back up, and i dont want to take the engine out of the car, is there any tool to make the valve go back up or there is any way to do it?? People told me that i can crank it by and , but i dont know how to do it where do i have to do it, i need help please im begging for help!

- As you've been asking this question for a week now time and time again I guess its time for the Nasty one to set you straight, As I've been a mechanic for over 30 years my knowledge is vast and no further questions need to be asked, You screwed up! now that you have dropped the valves into the cylinders you have to remove the head or heads that you screwed up on, period, end of sentence, there is no other way, and no you will not need to remove the engine to remove the heads, But had you did a bit of research before diving into this without a clue you would have found that a simple length of clothes line or thin rope stuffed down the spark plug hole and turned the engine over by hand to bring the piston up and push the rope into the valves to hold them place would have saved you from pulling the heads off this POS, excuse me I meant fine piece of English engineering, by trying to turn the engine over now is just a good way to bend a valve, and for all you know the piston could have been at the bottom of its stroke and the valves fell out of there guides are not even in contact with the head, so with this said do some research on how to remove the heads on this thing and fix your screw up. Live and learn, you just opted to learn the hard way,

Send your message to us

Butterfly Valve DN750 BS5163 with Hand Wheel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches