Building Hoist Single Cage 3000kg for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

The electrical crane is installed on the top of the cage, and it is a necessary tool for increasing and decreasing the mast sections. After the base frame’s installation, the electrical crane can be used to lift the mast sections inside or on the top of the cage for adding them onto the top of the mast. Conversely, during the disassembling work, the crane also can be used to disassemble the mast sections. In addition, we also can equip the electrical crane specially used for lifting the rebar according to the customers’ requirements.

6. Safety device

This system aims to ensure the hoist runs safely, which is mainly composed of electrical motor braking, anti-drop safety device, top & bottom limit switches, top & bottom 3-phase switches, door limit switches and buffer device mounted in the base frame, overload protection system is available for option with extra cost.

The electrical motor brake is used for hoist’s normal stop, with electrical & magnetic braking theory. When the hoist runs, the brake is off; when the hoist stops, the brake is activated. This device can adjust the weariness clearance of the braking disk and ensure the braking to be safe and reliable.

Anti-drop safety device will be activated on the occasion of the cage’s accidentally dropping. It is the patent technology of us, makes braking properly and actively and also reduces the impact on all the structure. And this mechanism can also detect the brake disc’s wearing without opening the safety device, which is of high reliability, maneuverability and safety. The device’s features’ of less impact, no damage to the whole structure, zero error, are advanced technology both domestically and abroad.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

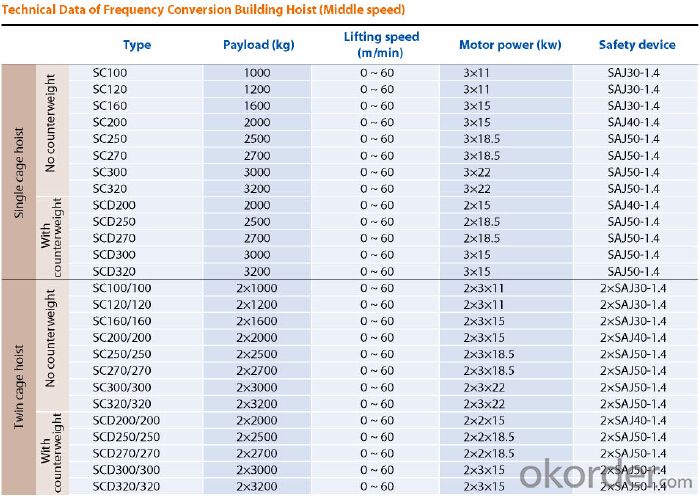

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q:Is there a specification requirement for the floor door of the elevator to the floor? How high

- The door locks must be in the direction of the elevator, and the people on the floor are not allowed to move at will, only the driver will be able to move. The other is that the height of the door must be 1.8 meters high, so that the workers' heads don't reach out to the danger.

- Q:6 layer of brick and concrete construction project, have tower crane still need construction elevator?

- 6 floors of brick and concrete construction projects, tower cranes do not need construction elevator. Brick structure refers to the building of the wall of vertical bearing structure, column, etc. By using brick or block masonry, lateral load-bearing beam, reinforced concrete structure is adopted for floor, roof boarding, etc. In other words, the masonry structure is a small amount of reinforced concrete and most brick wall bearing structures. The masonry structure is a kind of hybrid structure, which is composed of brick wall and reinforced concrete beams. Suitable for small width and depth, room area is small, multilayer or low-rise buildings, for load bearing walls can't change, while the frame structure of wall body can be altered.

- Q:How does the elevator operate

- The application of the construction elevator has gained popularity over the years, and has attracted many employees. The construction elevator is a highly skilled industry, so it is required that the professionals must master certain expertise. Here is a knowledge of how to operate a lift machine, hoping to help you.

- Q:How many people are there for construction workers

- The elevator is a vertical elevator with electric motors, which is equipped with box pods for multi-storey building and carrying goods. There is also a terrace, which is running continuously on the crawler, commonly known as escalator or automatic walkway. A fixed lifting device for the floor. Vertical elevator has a car, running on at least two columns of the vertical or Angle is less than 15 ° between the rigidity of rail. The size and structure of the car is convenient for passengers to enter or unload cargo. Traditionally, the elevator is the general term for vertical transportation in buildings, no matter how they are driven. Speed can be divided into low speed elevator (1 m/s), rapid elevator (1 ~ 2 m/s) and high speed elevator (2 m/s). Hydraulic elevators were introduced in the mid-19th century and are still being used in low-rise buildings. In 1852, the United States developed a safety elevator for wire rope lifting. In the 1980s, there was further improvement in drivers, such as the electric motors, which were driven by worm gears to turn the winding drum and balance weight. At the end of the 19th century, the friction wheel drive greatly increased the lift height.

- Q:What is the need for the sc200/200 construction elevator cable?

- General is 3 times 16 + 2 * 6, want to know can seek professional construction lift machine cable market manufacturer ask

- Q:A lift motor is 7.5 KW, and the frequency converter sends current 4.2 A, which has A heating resistance in the converter, and how the charge is calculated when the lift is full. Or consider the power of the converter and the power of the thermal resistance.

- The full load is 7.5 KW. The output current is 4.2 A, is the converter 7.5 KW?

- Q:How does the construction lift fall without electricity

- The lockers are finished with the report, unless there is a problem

- Q:Safe use of construction elevator

- 1, seek professional installation. 2, pay attention to safety when using, don't worry, because the elevator is not as fast as the elevator. 3, if there is a broken part, change it quickly, don't delay and feel free

- Q:The tower crane is on a surface with the construction elevator, and only 2 or 3 meters away. Is that allowed

- Cranes and elevators from very close, may be the reason for the sites or the position is not reasonable, so close to the distance as long as you ensure the tower crane and tower crane arm when rotating to the above the elevator after satisfying the end, must keep more than 2 meters with elevator recent distance. Or you can refer directly to the tower crane safety code, GB5144-2006.

- Q:What is the height of protecting door protection of construction elevator

- Elevator protection door is strict according to the mandatory standard to set up elevator well protection measures for safety technology. The shaft must be set in the range of 1.5 to 1.8, with protective railings or fixed gate and protective railings or fixed doors. 2, elevator well in plus or minus zero layer need to set up the first safety net, every two layers, the upper part of most every 10 m AnQuanPing network design, network security quality must gb5725-1997 "safety net" of standard network, methods must be checked in accordance with the relevant provisions. Installation in the safety net elevator dismantlement, the operator should wear the seat belt according to the regulation. On the floor and roof, a short side hole is larger than 1.5 m, the hole should be set in the requirement of the protective railing, the bottom setting safety net. To set safety warning signs that meet national standards in the elevator shaft. Safety warning signs are clear, warning lights should be set at night. The protective railings and gates shall be marked with yellow and black stripes and shall be manufactured according to the standards of construction safety technical specifications. 5, elevator wellhead protection facilities need to dismantle or change temporarily, and by the project full-time safety sign shall be the responsibility of the project director, and ready to move or change the security countermeasures. To inform all staff at the same time; Recovery after safety facilities must be by the project director, full-time security personnel and other related personnel on-site inspection management, qualified rear can continue to use.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Hoist Single Cage 3000kg for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords