Multifunctional Building Hoist

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 30 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

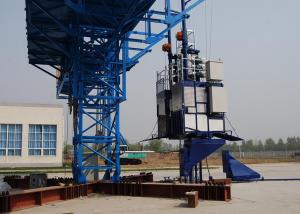

Description of CAMX Building Hoist SC200/200

The Multifunctional Hoist in such super high-rise buildings as the hyperbola cooling tower and the high chimney of the power plants, can carry workers, concrete and the long reinforcing bars. The hopper fixed by four pin rolls under the cage and the long reinforcing bars transportation system can be removed conveniently. In addition, we also manufacture multifunctional building hoist SC200 (single cage, with loading capacity of 2000kg), SC160/160(double cages, with loading capacity of 1600kg/1600kg), SC160 (single cage, with loading capacity of 1600kg).We also manufacture other styles according to the client's special requirements.

We has passed ISO9000 quality system authentication. We have powerful R&D centre and professional customer support team. Excellent quality and service are what we actually supply with.

Features of CAMX Building Hoist SC200/200

It is applied to carry workers, concrete and long reinforcing bars in construction of high-rise buildings, especially for power construction fields like high chimney, hyperbola cooling tower, bridge and dam. Since we launched multifunctional hoist, they have been adopted in construction of over 60 power plants in

Our multifunctional hoist has replaced traditional methods for construction of cooling tower and high chimney which together use goose-neck jib tower crane and windlass, and because it is installed inside of cooling tower for transporting of workers and materials, no another curve hoist is needed outside. So multifunctional hoists greatly reduce equipment demands and maintenance costs. Besides, our multifunctional hoist is praised for its friendly design that users can conveniently disassemble the transporting system of concrete and reinforcing bar, transferring it into a normal hoist.

Specifications of Multifunctional Hoist SC200/200

Lifting capacity | 2000kg/2000kg |

Lifting speed | 33 m/min, 38m/min, 0-60m/min (VVVF+PLC), 0-90m/min (VVVF+PLC) |

Max. lifting height | 400m |

Capacity of concrete hopper | 0.5m3/0.5m3 (1.5T/1.5T) |

Capacity of Rebar carrier | 600kg/600kg |

Max. length of the transported rebar | 9~12m |

Lifting speed of erection crane | 6m/min |

Motor type | Chinese motor or SEW motor |

Anti-drop safety device | With our patent |

Cage size (L x W x H) | 3.0x1.3x2.5m, 3.2x1.5x2.5m |

Mast section | 650x650x1508mm, 800x800x1508mm, hot dip galvanized or painted |

Anchor | distance 6-9m, hot dip galvanized or painted |

The whole machine can be designed according to your specific requirements | |

FAQ

Q:what is the capacity of concrete hopper?

A: Two hoppers equipped in SC200/200 for concrete transporting.

Each hopper with capacity of 0.7m3 ( 2T ), equal to 6~8 times of a cart

For example

H:100m, Speed 0~60m/min

Calculate with the load & unload time, 10 minutes for one transporting circle, 6 circles in one hour

So the concrete transporting capacity of SC200/200:

2×0.7×6= 8.4 m3/h

2×2×6= 24 T/h

Q: How about the capacity of reinforcing bar transporting

A: Multifunctional hoist can load reinforcing bars with the longest length of 9m, 600kg. Transporting system consists of bracket, clamp, and manual crane. They can be assembled and disassembled easily.

- Q:Do the elevator need to be installed when the main project is in construction

- In the construction of the main body, the construction elevator should be installed. The general construction is about 15 meters. The construction elevator is commonly called the construction elevator, but the construction elevator includes a broader definition and the construction platform belongs to the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. The construction elevator of our country is more and more mature, and gradually goes to the international. 3, building main body engineering means based on the above foundation, accept, for all the top load and construction project, maintaining structural integrity, stability and safety of bearing structure system.

- Q:6 layer of brick and concrete construction project, have tower crane still need construction elevator?

- Tower crane is used for heavy lifting, long pieces, small machinery and materials must be used in the construction elevator.

- Q:What is the need for the sc200/200 construction elevator cable?

- General is 3 times 16 + 2 * 6, want to know can seek professional construction lift machine cable market manufacturer ask

- Q:Is the construction elevator a special equipment

- Belong to special equipment construction lifter, but generally used as home building municipal engineering does not belong to the quality and technical supervision management, but belong to the administration of urban construction. Because the system of quality control unless invited, shall not be involved in military, aerospace, nuclear industry, mine, municipal, sea, railway locomotive hoisting machinery management.

- Q:How many kw is the sc construction elevator

- There is no fixed standard, which is widely adopted, 3X11KW, which is 33 kilowatts. The power of the motor is determined by the speed ratio of the decelerator. The most common lifter is 33 kilowatt, the speed ratio 1:16, 33 meters per minute.

- Q:Are there any good signs in the construction elevator door

- Above is construction, safety, please stay away from the ground.

- Q:The maximum allowable deviation of the vertical is the vertical degree when the construction elevator is installed

- 5 kinds of circumstances. 1: the height of the elevator guide frame is less than 70 meters, and the vertical deviation should not be greater than one in 1000 of the height of the guide frame. (assuming the rail frame is 70 meters high, the deviation cannot be greater than 70mm) 2: the rail frame is greater than 70 meters and is less than 100 meters, and the deviation is less than or equal to 70 mm. 3: the guide frame is larger than 100 meters and is less than 150 meters. The deviation is less than or equal to 90 mm. 4: the guide frame is larger than 150 meters is less than or equal to 200 meters. The deviation is less than or equal to 110 mm. 5: the guide frame is greater than 200 meters, and the deviation is less than 130 mm. This is based on the requirement of 5.2.2.1 from GB10054 to 2005. (it used to be a direct copy.)

- Q:Safety device for construction elevator

- When the cage is in an emergency for various reasons during the operation, the driver can press the stop switch at any time, making the cage stop running. The fast stop must be a non-self-restoring safety device, usually installed in the top of the cageConstruction lifter lifting door, protective enclosure door are equipped with electric interlock switch, which can effectively prevent because of hoisting cage or protective enclosure door open it up and running and materials caused by falling, only when the hoisting cage door and protective enclosure fully closed to start running.

- Q:What is the safety device for construction elevator?

- A lot of 1, anti-drop safety device 2, upper and lower limit 3, extreme limit 4, buffer spring 5, line door limit switch Single line door limit switch 7, ceiling switch 8, enclosure door lock 9, single door lock The door lock is on and off There are also many electrical safety protections

- Q:The construction elevator always jumps

- The starting current is more than three times the running current, and your air switch is low in the maximum current

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 1990 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Southeast Asia;South America |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 300 |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Multifunctional Building Hoist

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 30 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords