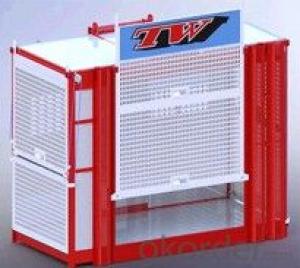

SC200/200 Construction Lift Elevator

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set watt

- Supply Capability:

- 30 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Building SC200/200 Construction Lift,Construction Elevator

hoisting speed :36m/min

max lifting height :300m

rated loading capacity :2*2000kg

Cage Dimension: 3.0*1.3*2.4(m)

Mast Section: 6.5*6.5*1.508(m)

Main Material: Φ 76 X 6/ 20

Motor: 3X2X 11 KW

Commercial Terms

Price: Negotiable

Delivery time: 15-20 days

capacity lifting speed etc.can be selected according to requirement of customer .

special cage dimension can be made according to requirement of customer .

- Q: This question asks for the method to adjust the tension of ropes or cables in lifting equipment such as a building hoist.

- <p>Adjusting the tension on ropes or cables in lifting equipment like a building hoist involves several steps. First, ensure the equipment is turned off and secured to prevent any accidents. Then, locate the tensioning mechanism, which could be a ratchet, turnbuckle, or a similar device. Gradually adjust the mechanism to tighten or loosen the cable as needed. Use a tension meter to measure the tension and ensure it meets the manufacturer's specifications. Regularly inspect the cables for wear and damage, and replace them if necessary. Always follow the equipment's manual for specific instructions and safety guidelines.</p>

- Q: Construction elevator positioning should consider which problems

- First make sure that the whole fence can be put down, and there should be no other extension of the fence that does not interfere with the lifting up and down of the cage Considering the length of the wall support, ensure the effective adjustment of the enclosed wall Then consider the installation of the wall support Consider whether access to the building is appropriate Some sites have been put into buildings directly, and some sites have considered scaffolding between them

- Q: The construction elevator always jumps

- The starting current is more than three times the running current, and your air switch is low in the maximum current

- Q: This question asks for measures to protect lifting equipment from damage during its operation.

- <p>To prevent damage to lifting equipment during operation, ensure regular maintenance and inspection are conducted to check for wear and tear. Adhere to the equipment's load limits and never exceed them. Use appropriate lifting techniques and ensure the load is balanced. Keep the equipment clean and free from debris. Train operators thoroughly on safe operating procedures. Avoid sudden starts or stops, and ensure all safety features and guards are in place and functioning correctly. Regularly check cables, hooks, and other critical components for any signs of damage. Always follow the manufacturer's guidelines and industry safety standards.</p>

- Q: What are the benefits and drawbacks of utilizing a building hoist in construction?

- <p>Advantages of using a building hoist include increased efficiency in material transportation, reduced manual labor, and improved safety by minimizing the risk of accidents associated with manual handling. They can also speed up construction timelines by allowing for continuous material flow. Disadvantages include the initial cost of the hoist, the need for regular maintenance, and potential downtime in case of mechanical failure. Additionally, building hoists may have limited capacity and may not be suitable for all types of construction projects, especially those with irregular shapes or limited space for installation.</p>

- Q: This question asks for a list of various types of cables that are utilized in lifting equipment.

- <p>Lifting equipment employs several types of cables, each designed for specific purposes. The primary types include: 1. Wire ropes, which are the most common and are used for their strength and flexibility. 2. Chain slings, which are strong and durable but less flexible than wire ropes. 3. Synthetic slings, made from materials like nylon or polyester, offering lighter weight and resistance to chemicals. 4. Round slings, providing a smooth surface to protect loads from damage. 5. Wire rope slings, which are versatile and can be used in various configurations. 6. Aircraft cables, known for their high strength and resistance to corrosion. 7. Endless wire rope slings, which are used for heavy loads and offer a looped design. Each type of cable has its own set of advantages and is chosen based on the specific requirements of the lifting task.</p>

- Q: This question asks about the routine maintenance procedures for a building hoist, which is a piece of equipment used in construction to lift materials and personnel.

- <p>To maintain a building hoist, follow these steps: Regularly inspect the hoist for any signs of wear or damage, especially the cables, pulleys, and safety mechanisms. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prevent rust. Ensure all safety features, such as emergency stops and limit switches, are functioning correctly. Keep the hoist clean and free from debris, which can interfere with its operation. Check the electrical connections for any signs of corrosion or damage. Perform load tests to confirm the hoist's lifting capacity and ensure it meets safety standards. Always follow the manufacturer's maintenance schedule and guidelines, and have a professional service the hoist periodically.</p>

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: This question asks whether a building hoist can be utilized both indoors and outdoors and seeks an explanation for its suitability in both environments.

- <p>A building hoist can be used both indoors and outdoors, depending on the specific design and construction. Outdoor hoists are typically built to withstand weather conditions and are more robust, while indoor hoists are designed for controlled environments. The choice between indoor and outdoor use is determined by factors such as the building's structure, the materials being lifted, and the environmental conditions. Outdoor hoists may require additional features like weatherproofing and corrosion resistance, whereas indoor hoists focus on efficiency and ease of use within a protected setting.</p>

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SC200/200 Construction Lift Elevator

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set watt

- Supply Capability:

- 30 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords