Aluminium Prepainted Coil with PVDF/PE 1XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Prepainted Coil with PVDF/PE 1XXX:

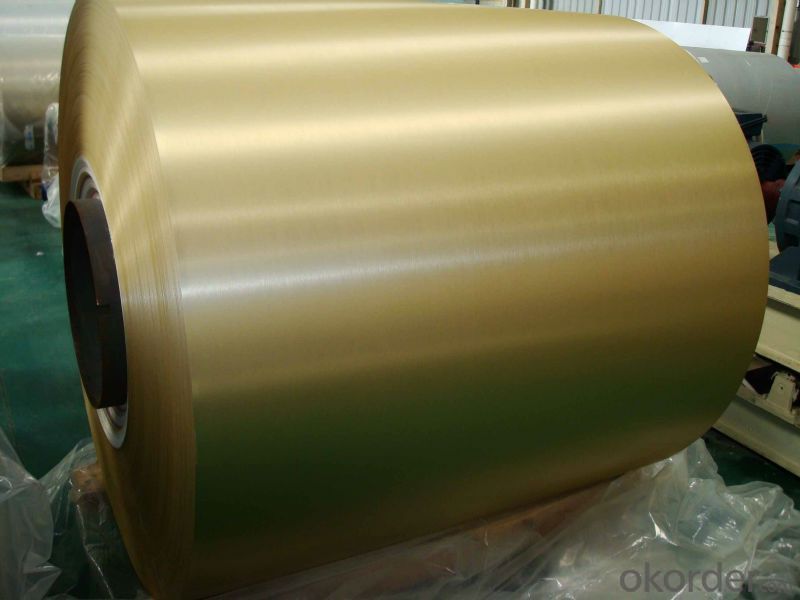

Aluminium Prepainted Coil with PVDF/PE 1XXX are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Prepainted Coil with PVDF/PE 1XXX:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

Images of Aluminium Prepainted Coil with PVDF/PE 1XXX:

Aluminium Prepainted Coil with PVDF/PE 1XXX Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q:wood aluminium windows?

- Does this mean the vinyl or aluminum is laminated over the wood? I do not know of the aluminum over owod. Aluminum transfers heat and cold very well, so vinyl is much better. Vinyl does not oxidize and is a standard on windows today. There are viyl clad wood windows, for people who like real wood inside, but none of the maintenance headaces of real wood outside.

- Q:How much is one square aluminum gate and five hard door?

- Double layer aluminum alloy, in the middle of the 5 bars, ordinary white or beige is 215, a square, the motor, in addition, the general 600KG copper core motor has 550 sets, there are 680 sets.

- Q:What is color aluminum coil?

- Colored aluminum coil is that the aluminum alloy whose surface has been shaded. The surface color after special treatment will not fade within 30 years at least because of the stable performance and good corrosion resistance. The weight per unit volume of color aluminum coil is the lightest among metal materials because of the low density and high hardness. Color aluminum is a newly emerging material in the field of doors and windows. Compared with steel, the biggest advantage is unparalleled firmness, varied colors and non-toxic for which steel has always been blamed. Therefore, it is widely used in areas such as doors and windows, sunroom and balcony seal. Color coated aluminum coil has become one of the most popular decorative material which is environmentally-friendly, durable and aesthetic. As a decorative material, it has the following unparalleled advantages: uniform color, bright and clean, strong adhesion, durability, anti-acid and anti-alkali, corrosion resistance, wind and weather resistance, decay and abrasion resistance and ultraviolet proof. Products categories: polyester coated aluminum coil (PE) and perfluorocarbon coated aluminum coil (PVDF).

- Q:What are the factors that affect the cost of aluminum coils?

- There are several factors that can affect the cost of aluminum coils, including the current market demand and supply, the quality and grade of the aluminum used, the size and thickness of the coils, transportation and logistics costs, currency exchange rates, and any applicable taxes or tariffs.

- Q:Some properties of aluminum are summarized in the following list.normal melting point 658°C heat of fusion 3.95 kJ/g normal boiling point 2467°C heat of vaporization 10.52 kJ/g specific heat of the solid 0.902 J/g°C Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point? In KJCalculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C? In KJCalculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C? In KJ

- Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point in KJ- 1.58 mol x 26.98 g/mol x 0.902 J/g°C x (658 - 33)°C x 1 kJ/1000 J = 24.03 kJ Calculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C In KJ- 1.02 mol x 26.98 g/mol x 3.95 kJ/g = 108.7 kJ Calculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C In KJ- 1.02 mol x 26.98 g/mol x 10.52 kJ/g = 289.5 kJ

- Q:Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. The disposal of aluminum coil waste is subject to various environmental regulations to ensure proper handling and prevent any potential harm to the environment and human health. One of the key regulations is the Resource Conservation and Recovery Act (RCRA) in the United States. Under this act, aluminum coil waste is considered a hazardous waste if it exhibits certain characteristics such as ignitability, corrosivity, reactivity, or toxicity. If the waste meets these criteria, it must be managed as hazardous waste and disposed of in accordance with RCRA regulations. This may involve treatment, storage, and disposal at an approved hazardous waste facility. Additionally, the Environmental Protection Agency (EPA) has established guidelines for the disposal of non-hazardous aluminum coil waste. These guidelines typically require proper storage, labeling, and transportation of the waste to an authorized disposal facility. The disposal facility should be equipped to handle and process the waste in an environmentally responsible manner. In many countries, including the United States, local, state, and federal regulations may also apply to the disposal of aluminum coil waste. These regulations may vary depending on the specific location and the nature of the waste. It is crucial for businesses and individuals involved in the disposal of aluminum coil waste to familiarize themselves with the applicable regulations to ensure compliance and avoid potential penalties. Overall, it is important to follow the specific regulations for the disposal of aluminum coil waste to protect the environment, prevent pollution, and ensure the safety of individuals involved in waste management.

- Q:Can aluminum coils be used in the production of aluminum gutters?

- Aluminum gutters can indeed be produced using aluminum coils. In fact, aluminum coils are commonly employed in the manufacturing process of aluminum gutters. These coils are crafted from an aluminum alloy, which happens to be a material that is both lightweight and long-lasting. By utilizing specialized machinery, these coils are expertly molded into the desired gutter profile. The utilization of aluminum coils enables the production of gutters to be efficient and precise, thereby guaranteeing a top-notch final product. Furthermore, aluminum possesses the advantageous quality of being resistant to corrosion, rendering it an ideal material for gutters that will be exposed to various weather elements like rain and snow. All in all, due to their durability, strength, and corrosion resistance, aluminum coils prove to be an excellent choice for the production of aluminum gutters.

- Q:Are aluminum coils suitable for electrical conductors?

- Yes, aluminum coils are suitable for electrical conductors. Aluminum is a good conductor of electricity, second only to copper in terms of conductivity. It is widely used in various electrical applications, including power transmission lines, wiring, and electrical coils. Aluminum coils offer excellent electrical conductivity while also being lightweight, cost-effective, and resistant to corrosion.

- Q:How are aluminum coils joined in a continuous process?

- Aluminum coils are typically joined in a continuous process through a technique called welding, specifically a process known as continuous welding or continuous coil welding. This involves feeding the adjacent ends of the coils through a welding machine, which uses heat and pressure to fuse the metal together. This continuous welding process ensures a seamless and strong joint between the aluminum coils, allowing for efficient and uninterrupted production.

- Q:What are the different types of edge conditions for aluminum coils?

- There are several different types of edge conditions for aluminum coils, each serving a specific purpose and application. These edge conditions are designed to provide protection, enhance functionality, and ensure compatibility with various manufacturing processes. 1. Mill Edge: This is the standard edge condition produced during the initial rolling process at the mill. It is characterized by a smooth, straight, and burr-free edge. Mill edge coils are suitable for general applications and can be easily processed further. 2. Slit Edge: Slit edge coils are created by cutting the mill edge coils into narrower widths. This process removes a small strip of material along the edges, resulting in a slightly rougher edge compared to mill edge coils. Slit edge coils are commonly used in applications where precise width tolerances are required. 3. Trimmed Edge: Trimmed edge coils undergo further processing to remove irregularities or defects along the edges. This edge condition is achieved by shearing or trimming the coil to eliminate any imperfections. Trimmed edge coils are often used in applications that demand a high level of aesthetics or require a uniform appearance. 4. Deburred Edge: Deburring is a process that involves removing any sharp edges or burrs from the coil. This edge condition is achieved through mechanical or chemical methods, ensuring a smooth and safe edge. Deburred edge coils are commonly used in applications where safety is a concern, such as in the manufacturing of consumer goods. 5. Rounded Edge: Rounded edge coils have their edges rounded or softened to reduce the risk of injury during handling or installation. This edge condition is achieved through a variety of methods, including roll forming or edge rolling. Rounded edge coils are often used in applications where safety is paramount, such as in the construction industry. 6. Specialty Edge Conditions: In addition to the standard edge conditions mentioned above, there are also specialty edge conditions available for specific applications. These may include edge conditions designed for specific manufacturing processes like welding, bending, or forming. Specialty edge conditions are tailored to meet the unique requirements of certain industries or applications. It is important to select the appropriate edge condition for aluminum coils based on the specific requirements of the application. Factors such as aesthetics, functionality, safety, and manufacturing processes should all be considered when determining the most suitable edge condition.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Prepainted Coil with PVDF/PE 1XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords