PP Biaxial Geogrid for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

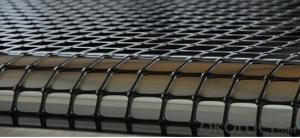

1. Introduction of PP Biaxial Geogrid

PP Biaxial Geogrid is manufactured from Polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

The reinforcing action of PP Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill.

2. Features of PP Biaxial Geogrid

High tensile strength at both longitudinal and transverse direction

3. Application of PP Biaxial Geogrid

Soft foundation reinforcing for highway, railway, slope protecting projects, landfill sites.

4. Technical Data and Specification of PP Biaxial Geogrid

Property | Test Method | TGSG 15-15 | TGSG 20-20 | TGSG 30-30 | TGSG 40-40 | |

Ultimate tensile strength(1) (kN/m) | MD |

ASTM D 6637 | 15 | 20 | 30 | 40 |

CD | 15 | 20 | 30 | 40 | ||

Elongation at maximum load (%) | MD | 13 | ||||

CD | 13 | |||||

Tensile strength at 2 % elongation (kN/m) | MD | 5 | 7.5 | 10.5 | 14 | |

CD | 5 | 7.5 | 10.5 | 14 | ||

Tensile strength at 5 % elongation (kN/m) | MD | 7 | 14 | 21 | 28 | |

CD | 7 | 14 | 21 | 28 | ||

Minimum Carbon Black | % | ASTM D 4218 | 2 | |||

Dimensions

Roll Length(m) | 100/50 |

Roll Width(m) | 2/3.9/3.95 |

5. Loading Quantity for one 40HC.

TGS15-15, 300rolls, 59250m2

TGS20-20, 220rolls, 43450m2

TGS30-30, 144rolls, 28440m2

TGS40-40, 100rolls, 19750m2

6. RFQ:

1) What's your payment terms?

T/T, L/C at sight, etc

2) What's your delivery time?

Within 15-20days against your deposit or original L/C received

3) Can you accept third party test?

Yes, we can accept it totally, SGS, BSJ, etc are no problem for us.

4) Can you provide free samples?

Yes, we can supply but express fees are usually on buyer's account.

- Q:High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester polyester geogrid.Turn left and turn right |

- Q:What is a plastic geogrid? What do you say is a one-way geogrid?

- It can be divided into two kinds, one way and two way.

- Q:How do geogrids help in reducing construction costs?

- Geogrids help in reducing construction costs by providing reinforcement and stabilization to soil, allowing for the use of less expensive and lower quality materials. They also minimize the need for excavation, backfill, and compaction, resulting in reduced labor and equipment costs. Moreover, geogrids enhance the lifespan of structures by preventing soil erosion and settlement issues, reducing the need for costly repairs in the long run.

- Q:Can geogrids be used in reinforcement of foundation slabs?

- Yes, geogrids can be used in the reinforcement of foundation slabs. Geogrids are widely used in civil engineering projects to improve the stability and load-bearing capacity of soil. When placed in the foundation slab, geogrids help distribute the load more evenly, reducing the risk of cracking and settling. Additionally, geogrids provide enhanced resistance to lateral forces and can help mitigate the effects of soil expansion and contraction. Overall, geogrids can greatly improve the performance and longevity of foundation slabs.

- Q:Are there any environmental concerns associated with geogrids?

- Yes, there are some environmental concerns associated with geogrids. For instance, the production of geogrids may require the use of non-renewable resources, such as petroleum-based materials. Additionally, the disposal of geogrids after their useful life can contribute to waste generation. However, when used properly and in accordance with environmental guidelines, geogrids can offer numerous benefits for soil stabilization and erosion control, making them a valuable tool in sustainable construction practices.

- Q:Are geogrids suitable for reinforcing railway subgrades?

- Yes, geogrids are suitable for reinforcing railway subgrades. Geogrids are specifically designed to improve the stability and strength of soil and can effectively distribute loads, reduce settlement, and prevent lateral movement. They are commonly used in railway construction and maintenance projects to enhance the performance of subgrades by providing additional support and increasing load-bearing capacity.

- Q:Can geogrids be used in soil stabilization for slopes?

- Yes, geogrids can be used in soil stabilization for slopes. Geogrids are commonly used to reinforce and stabilize soil slopes by providing tensile strength and reducing the risk of slope failure. They help to distribute loads and increase the stability of the soil, making them an effective solution for slope stabilization projects.

- Q:What are the differences between geogrids and geotubes?

- Geogrids and geotubes are both geosynthetic materials used in civil engineering and environmental applications, but they have distinct differences. Geogrids are typically made of polymer materials and are designed to provide soil reinforcement and stabilization. They have a grid-like structure with open spaces and are used to improve the strength and bearing capacity of soils. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geotubes are large, tubular containers made from high-strength woven or non-woven geotextile fabrics. They are used for shoreline protection, coastal erosion control, and dewatering applications. Geotubes are filled with sediment, sludge, or other materials and then dewatered, allowing water to escape while retaining the solid contents. They are often used in coastal engineering projects to create or restore beaches, control erosion, and contain contaminants. In summary, while geogrids are used for soil reinforcement and stabilization, geotubes are used for dewatering and containment purposes in coastal and environmental applications.

- Q:Fiberglass grille width

- Geogrid, fiberglass geogrid

- Q:How do geogrids help in reducing construction equipment requirements?

- Geogrids help in reducing construction equipment requirements by providing soil stabilization, reinforcement, and confinement. They distribute the load across a wider area, reducing the need for heavy machinery and excavation. This results in cost savings, less fuel consumption, and faster construction processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial Geogrid for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords