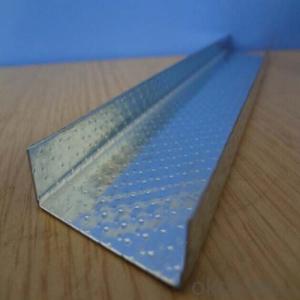

Galvanized Steel Profiles Drywall Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

Specification

Galvanized Steel Specification

Pls kindly check our regular size as below,if you need other special size and thickness,pls contact us we will try our best to follow you or your engineer.

Item | Regular Size(mm) | |||

Thickness | Heught | Width | Length | |

Furring Channel | 0.4 | 22 | 35 | 3000.00 |

0.45 | ||||

0.5 | ||||

C Channel | 0.4,0.45,0.5 | 10 | 38 | 3000.00 |

0.45,0.5,1 | 12 | |||

L-Angle | 0.4,0.45,0.5 | 24 | 24 | 3000.00 |

25 | 25 | |||

Stud | 0.45,0.5,0.6 | 48 | 50 | 3000.00 |

48 | 75 | |||

32(34.5) | 73 | |||

Track | 0.45,0.5,0.6 | 40 | 50 | 3000.00 |

40 | 75 | |||

25 | 75 | |||

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Gypsum board partition wall how to sound insulation

- Close the gypsum board to install the keel, filled with rock wool in the keel, and then use the gypsum board with a screw on the keel, you can achieve adequate sound insulation. If you want a better sound insulation, you can use thicker gypsum board.

- Q:Light steel keel partition wall construction process is what

- (1) Pin line, sub-file: in the partition with the upper and lower and the two sides of the matrix at the junction, should be the width of the keel line. Battle clear, accurate location. According to the design requirements, combined with the cover panel of the long and wide sub-file to determine the vertical keel; transverse and additional keel position. (2) for the pillow: when the design requirements, according to the design requirements for the concrete pillow. For the pillow should be supporting mold, bean stone concrete should be pound dense. (3) fixed along the edge, along the keel; along the line position fixed along the edge, along the keel, can be fixed with nails or expansion bolts, fixed point spacing should not be greater than 600mm, keel docking should remain straight.

- Q:75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Theoretically, the main factors influencing the sound insulation of the gypsum board wall are as follows: 1) the law of quality: there is a common law for the insulation of the partition, that is, the heavier the material (the greater the surface density) the better the sound insulation. For a single layer of dense uniform wall, surface density for each doubled, the sound insulation in the theoretical increase of 6dB, this law is the law of quality. For the double layer of gypsum board wall, the law of quality plays an important role, that is, to increase the number of layers or thickness of the board can be improved sound insulation. As the keel double wall system sound vibration form is very complex, so the embodiment of the law of quality than the simple single-wall complex. 2) Resonant frequency: any partition wall there is an inherent resonance frequency, when the sound wave frequency and wall resonance frequency, the wall as a whole resonate, the frequency of the sound insulation will be greatly reduced.

- Q:What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q:How to install light steel keel gypsum board wall

- Light steel keel gypsum board installation should generally be through the following steps: wall line → wall construction → installation along the ground, along the top keel → installation of vertical keel → fixed door and window makeup → installation of the wall side of the gypsum board → install another side of the plaster price → seam processing → wall decoration. 1. Wall line According to the design of the wall, in the ground to release the wall bit line, and the line leads to the ceiling and side walls. 2. Wall construction First on the wall and floor, ground contact parts for cleaning, coated with interface treatment agent together, then pouring C20 concrete wall, the wall surface should be smooth, both sides should be vertical. 3. Install the edge along the top keel Along the ground, along the top keel in place, with the nail fixed, shot nail from the 900mm, the location of the nail should avoid the laying of the tube area. 4. Install the vertical keel According to the determined vertical keel spacing, along the ground, along the top keel on the line drawing line. The vertical keel is arranged by the end of the wall. When the doors and windows are provided with windows and doors, they should be arranged from one side or both sides of the door window. When the last keel from the wall of the size is greater than the provisions of the keel spacing, you must add a keel. The upper and lower ends of the keel should be fixed along with the top, along the keel with rivets or tapping screws.

- Q:The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q:100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- Light steel keel a 3 meters, just the height of the wall is 3m, vertical wall keel is not a waste of material.

- Q:Light steel keel gypsum board partition design should pay attention to what the problem

- Light steel keel is attached to the gypsum board, it can be seen, the installation of light steel keel spacing is based on the thickness of the gypsum board to decide. Like the 12mm gypsum board, its spacing is 450mm, according to the gypsum board to determine its spacing. Finally, in the adjustment of hanging pieces into the keel inside the appropriate rotation can be consistent.

- Q:Light steel keel partition wall fire retardant coating shabu several surface

- Brush when, in accordance with the requirements, at least need to brush twice. Although the Tai Po people in practice only brush it again, but suggest that you still brush twice for safety.

- Q:Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Profiles Drywall Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords