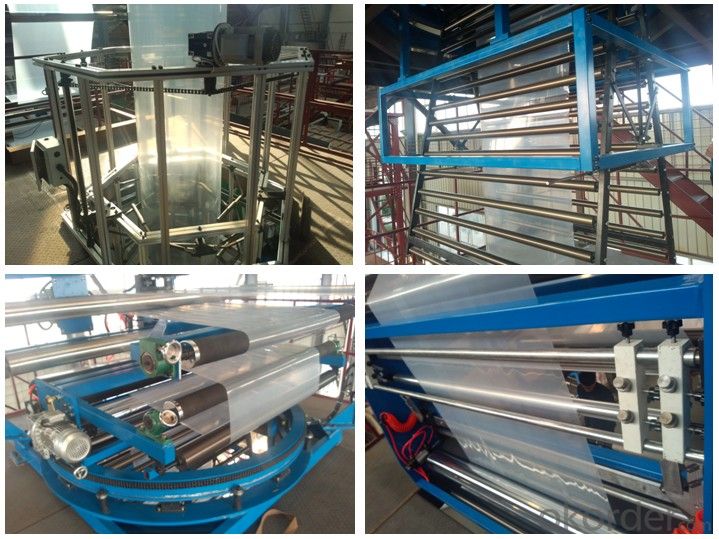

Seven layer Film Blowing Machine for Food Package

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1, Main Technical Parameters

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

2, Configuration

2.1 Extrusion system (Extruder)

Equipped with 5sets of SJ55x32 and 2set of SJ65x32 single screw extruder which have

advantages of good production efficiency, low energy

consumption and good plasticization.

2.2 Die head system

Die head is introduced the advanced German technology, through CAD optimal design,

processed with German TC2.8K four-axis simultaneous machining center. The die will have

features of high precision, good brightness without deformation.

2.3 IBC system

IBC (ultrasonic closed-loop servo-control) system is consists of gas exchange device,

internal cooling air ring, in/out air blower, signal detection and control circuits, etc. The

system can rapidly cooling the bubble, exhaust inner heat, water molecules and emissions

of bubble, supply new cooling air, cool the inner temperature of the bubble, increase the

production output and improve the mechanical properties of films.

2.4 Traction system

Horizontal ±360°reciprocating rotary can guarantee the linear velocity of film product

always stay consistent. The driving mechanism, haul off device and V-shaped plate hauls

the bubble for 360°uniform rotary at the speed of 0.1-0.3r/min to make the film deviation

which caused by die head, air ring and tower frame being 100% randomly distributed, thus,

to guarantee the whole quality of formed film product.

2.5 Automatic winding system

With the features of advanced technology, safe operation, easy maintenance, the winding

system can automatically change, cut and unload the rolls, which highly reduces the labor

costs and enhances the effectiveness.

2.6 Computer control system

Control method: Mitsubishi PLC control technology

2.6.1 One set of main control cabinet, adopts one set of three-in-one cabinet. (AC

contactor, low voltage fault positioner from Schneider, SSR from Taiwan Yangming)

2.6.2 Display part: adopts 10.4" touch screen for the operation (traction, winding, metering,

IBC, synchronous tension, cooling control of inlet/outlet blower).

2.6.3 Yaskawa frequency inverter for extruder motors, and domestic frequency inverters for

the rest.

- Q:What is the difference in the filtration accuracy between the electrostatic oil purifier and the filter cartridge filter?

- The electrostatic oil purifier can effectively absorb impurities from 0.02 M to 100 mu m, with high accuracy. Filter is mainly used to filter method, the accuracy of high and low, and the filter clogging. However, electrostatic adsorption is not easy to plug, and most of the adsorbed impurities are discharged from the machine

- Q:Why does the centrifugal oil filter filter out peanut oil? Why does it stink?

- Pour the washed wool oil evenly into the rotary drum

- Q:How about the rental fee for vacuum oil filter?

- This is not easy to say, general oil filters are to buy a better, after all, waste oil is often a loss, as long as the production will inevitably produce waste oil

- Q:What is the working principle of the oil filter?

- Working principle of oil filterThere is a rotor with double jet nozzle in its interior, only produced by oil pressure to provide the driving force. After the device is opened, the oil in the tank is sent to the rotor through the pump. When the oil is filled with the rotor, the nozzle is ejected along the lower part of the turntable

- Q:What kind of oil can the oil filter handle?

- 2, centrifugal oil filtration function of removing impurities and a small amount of water, such as: common oil with refrigeration oil, quenching oil, cold heading oil, etc., this kind of oil filter less oil processing, efficiency is not high.3, the vacuum oil filter function in addition to water and impurities, such as turbine oil, insulation oil, water and other heavy oil oil, high viscosity oil is best to use a vacuum oil filter, if it is the ordinary oil filter, using heating equipment, such as heating plate oil filter, or composite vacuum oil filter type and frame type oil filter vacuum oil filter.

- Q:How often is the filter element of the turbine oil vacuum oil filter changed?

- 1, this depends on your own oil content of impurities, as well as vacuum filter oil filter itself quality and function. For example, your higher oil turbine impurity content, so it is easy to clog the filter clogging, need to clean or replace (note that some of the filter can be cleaned, and some can not be bought, when the oil filter need to ask, and generally can clean the filter than cleaning the filter element to the high price); and if the purchase of oil filter machine as well as filter quality, low intensity, filtering accuracy is not good, the assimilative capacity is small, the filter is easy to jam.

- Q:How to use the centrifugal oil filter properly?

- 3) suspension gear pump directly into the centrifuge, the feed pressure in accordance with the concentration of suspension, viscosity and processing capacity, usually around 0.05-0.15MPa. The material must pass through the coarse material removal of debris, to prevent the discharge tube and centrifuge dusseldorf.4) the sediment sent by the centrifuge can be transported by belt conveyer, spiral propulsion shaft or artificial transportation, etc. the separated green liquid can be discharged by pipeline.

- Q:Pneumatic oil filter is slow, isn't it too low?

- The vacuum oil filter can filter water, and can also filter impurities, in which the function of filtering impurities is achieved by strong magnetic adsorption and filter blocking,

- Q:Why does the oil filter run out of vacuum? How can we solve it?

- The cause of the accident in the oil level is too high) vacuum separator solution) open the equipment town valve, in order to reduce the level of vacuum separator in Chongqing tonre oil company to remind all the new and old customers, if you want to save the trouble, the best is in the purchase of equipment, requires manufacturers, provided with vacuum oil filter automatic bubble elimination device., this device can effectively prevent the vacuum injection, so as to protect the safety of the vacuum pump, prolonging the service life of the vacuum pump, to ensure safe and reliable operation of the vacuum oil filter, and also has the advantages of simple operation, reliable operation, easy maintenance, so that the oil filter efficiency will be higher. The above is the oil filter operation in the common fuel injection phenomenon, troubleshooting methods, hoping to filter oil customers in all industries to bring convenience.

- Q:What is the working principle of the vacuum oil filter?It's easy to understand

- The gasification temperature of oil and water is different. Working in a vacuum can improve efficiency and control temperature to remove moisture in the oil

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Seven layer Film Blowing Machine for Food Package

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products