Heat Resistant Insulation Ceramic Fiber Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ceramic fiber blanket for boiler insulation:

1.Factory direct

2.ISO certificate

3.OEM service

4.Lowest price

Heat resistant insulation Ceramic Fiber Blanket Al2O3 52%-55% :

Heat resistant insulation Ceramic Fiber Blanket Al2O3 52%-55% :

♦ Needled blanket

♦ Non-combustible

♦ Low density and low thermal conductivity

♦ Shorter heat up and cool down time

♦ Resilience and resistance to thermal shock

♦ Flexible and easy to cut or install

♦ Consist of acoustic properties

♦ Contain no organic binder

♦ Asbestos free

Heat resistant insulation Ceramic Fiber Blanket Al2O3 52%-55% Advantage:

Competitive Price. Make the products competitive in your market.

Abundant Experience. Prevent cracks and twist in bricks.

Different Moulds. Save mould fees for you.

Strict Quality Control. Meet clients’ quality requirement.

Large stocks. Guarantee prompt delivery.

Professional Packing. Avoid damage and secure the goods in transportation

Heat resistant insulation Ceramic Fiber Blanket Al2O3 52%-55% Applications:

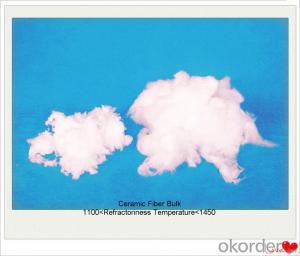

Ceramic Fiber Blanket is made of high purity Alumino-Silicate (and Zirconia) fibrous wool.

♦ Refractory back-up installation

♦ Direct exposure to heat as furnace hot face lining

♦ Expansion joint seal

♦ Fire protection

♦ General high temperature insulation

Heat resistant insulation Ceramic Fiber Blanket Al2O3 52%-55% specifications:

Physical and Chemical Indicators:

| 1260 Blanket | 1400 Blanket | 1500 Blanket | 1600 Blanket |

Classification temperature ( °C) | 1260 | 1425 | 1500 | 1600 |

Melting point (°C) | 1760 | 1700 | 1760 | - |

Colour | White | White | Blue gree | White |

Fiber diameter ( u m) | 2.6 | 2.8 | 2.65 | 3.1 |

Fiber length (mm) | ~250 | ~250 | ~150 | ~100 |

Linear shrinkage(%) | (1100oC x 24 hrs)1.8 | (1300 o C x 24 hrs) 1.5 | ||

Shot content (>212 micro meter) (%) | 18 | 18 | ||

Thermal conductivity Kcal/mh °C (W/mK) ,ASTM C201 | ||||

1260 blanket | 64 kg/m3 | 96 kg/m3 | 128 kg/m3 | 160kg/m3 |

mean 400°C | 0.13 | 0.12 | 0.07 | 0.09 |

mean 600 °C | 0.21 | 0.17 | 0.12 | 0.14 |

mean 800°C | 0.30 | 0.25 | 0.16 | 0.20 |

1400 blanket | 128 kg/m3 | 160kg/m3 | ||

mean 600 °C | 0.13 | 0.14 | ||

mean 800 °C | 0.20 | 0.20 | ||

mean1000 °C | 0.29 | 0.28 | ||

Chemical composition (%) | ||||

Al2O3 | 47.1 | 35.0 | 40.0 | 72 |

SiO2 | 52.3 | 49.7 | 58.1 | 28 |

ZrO2 | 15.0 | |||

Cr2O3 | 1.8 | |||

Bulk density(Kg/m3) | 64,96,128,160 | |||

Available size(mm/roll) | 7200*600*6,12.5,20,25,38;3600*600*50 | |||

- Q:Is aluminum silicate fiber poisonous?

- Ceramic fiber loose cotton is a kind of fluid which can melt high purity clay clinker, alumina powder, silica powder, chrome sand and so on in the industrial electric furnace.

- Q:Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q:The difference between the ceramic fiber blanket and rock cotton blanket

- Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining.

- Q:Is the ceramic fiber cloth poisonous?

- Ceramic fiber clothProduct introduction.Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q:What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q:What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q:Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

- Q:Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q:Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q:What is the diameter of the ceramic fiber? How to mix?

- The diameter of the general ceramic mineral fiber is 2---5 microns, and the length is in the range of 0---8 mm long.Ordinary mixing machine can be easily mixed, and the mixture of other good affinity, evenly dispersed and mixed resin or rubber and liquid glue, thus make the fiber products look pretty smooth, bright color, anti impact friction resistance, small abrasion, tensile Xinghao, can effectively reduce the noise without damage dual, can reduce the amount of metal fiber.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat Resistant Insulation Ceramic Fiber Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords