Isolation Non-woven Geotextile Fabric For Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Isolation:

Use geotextile to isolate the mate rials(soil and sand,sand and gravel,soil and concrete.etc.)

with different physical properties (particle size,distribution,denseness and density.etc.);

To maintain the structure and function of them so that the load bearing capacity is strengthened.

2.Filtration:

To make advantage of the good air and water permeability of the needle-punched geotextiles to let

water flow through;

To cut off the soil grains,fine sands,small stones.etc.effectively to maintain the stability of the

water-soil engineering.

3.Drainage:

Geotextile is a great material for water diversion that it can form a drainage channel inside the soil

so that the extra liquid and gas inside the soil structure is discharged.

4.Reinforcement:

Making use of the geotextile’s strong pull resistance and deform resistance to the stability of the

buildings’ structure in order to increase the soil’s quality.

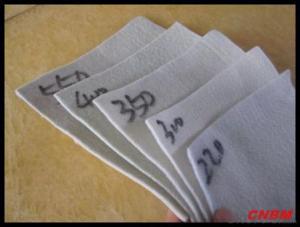

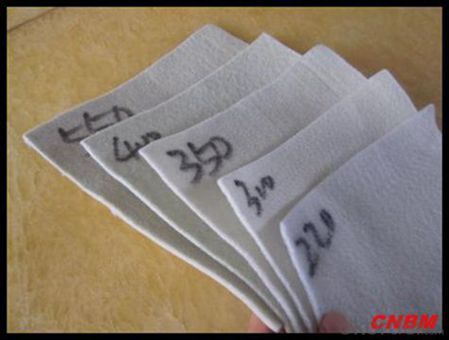

5. Non Woven Geotextile Product Show:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q:Are geotextiles commonly used in canal lining applications?

- Yes, geotextiles are commonly used in canal lining applications. Geotextiles provide excellent erosion control and filtration properties, making them an effective solution for preventing soil erosion and maintaining the integrity of canal linings.

- Q:How do geotextiles help in preventing soil erosion in agricultural fields?

- Geotextiles help in preventing soil erosion in agricultural fields by acting as a barrier between the soil and external forces such as wind and water. They stabilize the soil by reducing surface runoff, preventing sedimentation, and promoting the growth of vegetation. Geotextiles also enhance filtration and drainage, allowing water to flow through while retaining soil particles, thus minimizing the risk of erosion.

- Q:How do geotextiles help in preventing lateral spreading of soil?

- Geotextiles help in preventing lateral spreading of soil by acting as a barrier that stabilizes the soil and restricts its movement. These synthetic materials are placed between layers of soil to provide reinforcement and prevent the lateral displacement of soil particles. The geotextiles act as a separator, allowing water to pass through while retaining soil particles, thus reducing the potential for soil erosion and lateral spreading.

- Q:How do geotextiles contribute to the cost-effectiveness of construction projects?

- Geotextiles contribute to the cost-effectiveness of construction projects by providing several benefits. Firstly, they act as a barrier against soil erosion, reducing the need for costly erosion control measures. Secondly, geotextiles can improve soil stability and increase the load-bearing capacity of weak soils, eliminating the need for expensive soil stabilization techniques. Additionally, by acting as a separation layer, geotextiles prevent the mixing of different types of soils, reducing the amount of expensive fill material required. Lastly, geotextiles can prolong the lifespan of infrastructure by preventing the intrusion of fine particles and reducing the likelihood of soil settlement, saving on future maintenance and repair costs.

- Q:What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific material and application. In general, higher temperatures can lead to increased softening and deformation of geotextiles, reducing their overall strength and stability. Extreme heat can also cause geotextiles to lose their mechanical properties and become more susceptible to degradation. On the other hand, lower temperatures may cause geotextiles to become stiff and less flexible, potentially affecting their ability to conform to the underlying soil or rock. It is important to consider the temperature range in which geotextiles will be exposed when selecting and designing their use to ensure optimal performance and longevity.

- Q:What are the different geotextile weight classes and their applications?

- Geotextiles are categorized into different weight classes based on their mass per unit area. These weight classes range from lightweight to heavyweight. Lightweight geotextiles, usually less than 200 grams per square meter (gsm), are commonly used in erosion control applications, such as slope stabilization and vegetation support. They provide filtration and separation functions while allowing water to pass through. Medium-weight geotextiles, typically ranging from 200 to 400 gsm, are often employed in applications like road stabilization, embankment reinforcement, and subgrade separation. They offer a balance between strength and permeability, ensuring proper drainage and preventing soil movement. Heavyweight geotextiles, exceeding 400 gsm, are primarily used in applications requiring high strength and durability. These include shoreline protection, coastal engineering, and land reclamation projects. They provide robust reinforcement and act as a barrier against erosion and wave action. The choice of geotextile weight class depends on the specific engineering requirements of the project, such as soil conditions, anticipated loads, and desired drainage characteristics.

- Q:Can geotextiles be used in erosion control on riverbanks?

- Yes, geotextiles can be used in erosion control on riverbanks. Geotextiles are often used as a stabilization measure to prevent soil erosion by providing a barrier against water flow and supporting vegetation growth. They help to retain soil while allowing water to pass through, reducing the impact of flowing water on riverbanks and preventing further erosion.

- Q:Geotextile special staple fiber where needed

- Geotextile special staple fiber where needed

- Q:What are the key considerations for geotextile installation in seismic zones?

- Some key considerations for geotextile installation in seismic zones include the selection of a high-quality and durable geotextile material, ensuring proper anchoring and securing of the geotextile to prevent displacement during seismic events, and considering the potential for liquefaction or soil settlement in the design and installation process. Additionally, it is important to assess the potential for ground shaking and ground displacement in the seismic zone to determine the appropriate geotextile specifications and installation techniques.

- Q:Can geotextiles be used in shoreline erosion control projects?

- Yes, geotextiles can be effectively used in shoreline erosion control projects. Geotextiles are permeable fabrics that can be installed along shorelines to stabilize the soil and prevent erosion caused by waves and currents. They can be used as a layer to separate the soil from the water, allowing for water filtration while reducing soil erosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Isolation Non-woven Geotextile Fabric For Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords