304 Stainless Steel Sheet Building metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Building metal 304 stainless steel sheet

Item | Building metal 304 stainless steel sheet |

Standard | ASTM,AISI,JIS,EN,DIN,GB |

Surface | 2b ba HL |

Thickness | Cold rolled:0.3mm-3mm Hot rolled:3mm-100mm |

Width | 1000mm/1219mm/1250mm/1500mm/1524mm/2000mm, or as customer’s requires. |

Length | As customer’s requirements. |

Edge | Slit/Mill Edge |

Origin | TISCO,LISCO,JISCO,BAOSTEEL, Eastern Special Steel etc. |

MOQ | 1 Ton |

Price Term | FOB/CFR/CIF |

Delivery | 7-10 days after the deposit |

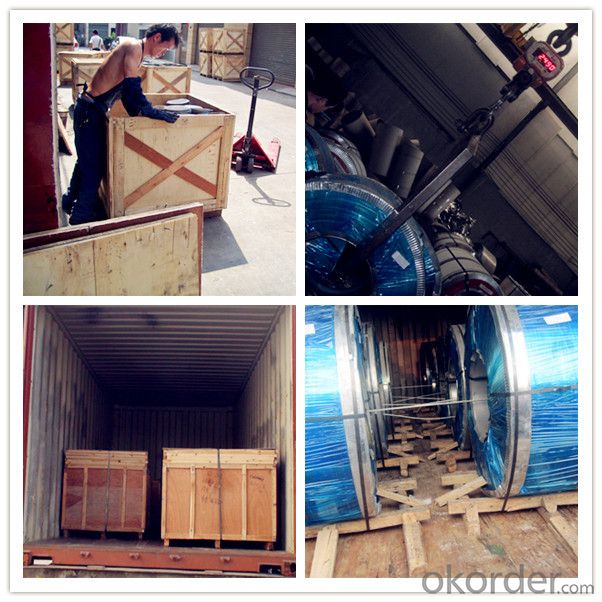

Packaging | Seaworthy Export Standard or as customer's requests. |

Application | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

2B | The surface brightness and flatness of 2B is better than 2D. Then through a special surface treatment to improve its mechanical properties, 2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100#200,have better brightness with discontinuous coarsestria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit#150#180,have better brightness with discontinuous coarsestria, but thinner than NO.3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc, |

HL | Polished with abrasive belt of grit#150#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc |

8K | The product have excellent brightness and prefect reflexivity can be the mirror |

More Products

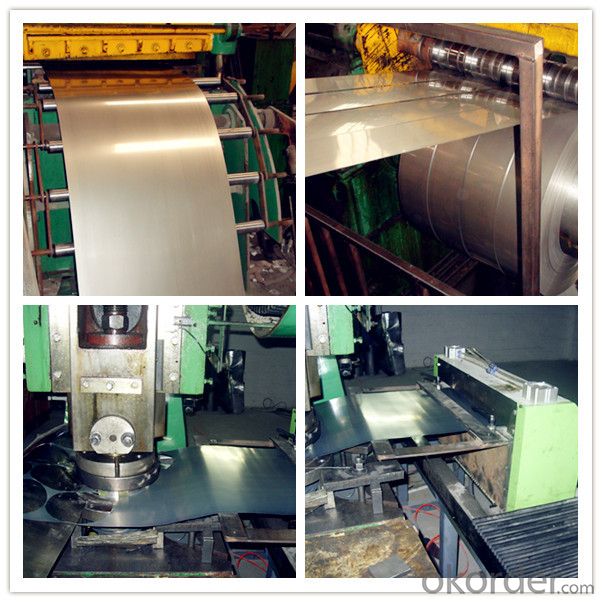

Manufacting

| Q&A corrugated steel sheet | |||||||

| 1 | Q: WHAT ARE YOUR MAIN PRODUCT? | ||||||

| A:We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip /Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube/ Stainless Steel Pipe Sheets. | |||||||

| 2 | Q: WHAT ARE YOUR ADVANTAGES? | ||||||

| 1. We have a strict quality control from production to delivery. 2. We use advanced system and tool to improve working efficiency and control every step. 3. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. | |||||||

| 3 | Q: CAN I GET FREE SAMPLE? | ||||||

| A: YES. We can provide free sample. But we are not responsible for the delivery fee . | |||||||

Packing & Loading

- Q:How do you prevent intergranular corrosion in stainless steel sheets?

- To prevent intergranular corrosion in stainless steel sheets, several methods can be employed. First, the selection of the appropriate stainless steel grade is essential. Grades with a low carbon content, such as 304L or 316L, are less susceptible to intergranular corrosion compared to higher carbon grades. This is due to their ability to minimize the formation of chromium carbide precipitates, which are the main cause of intergranular corrosion. Another method is heat treatment. Processes like solution annealing and quenching can help eliminate or reduce the formation of chromium carbide precipitates. By dissolving existing precipitates and promoting the formation of a protective chromium oxide layer on the surface, the corrosion resistance of the stainless steel is restored. Careful attention must also be given to welding techniques when working with stainless steel sheets. Processes like gas tungsten arc welding (GTAW) or laser welding, which provide precise control over heat input, are preferred. It is also advisable to use low carbon filler metals or consumables specifically designed for intergranular corrosion resistance to minimize the risk of corrosion. After welding, thorough cleaning of the welded area is crucial to remove any contaminants or oxide scales that could promote corrosion. Acid cleaning followed by passivation helps restore the protective oxide layer and enhances the stainless steel's resistance to intergranular corrosion. Lastly, it is important to avoid sensitization, which occurs when stainless steel is exposed to high temperatures for extended periods. Prolonged exposure to temperatures between 450-850°C (842-1562°F) during fabrication or service should be avoided to prevent sensitization and subsequent intergranular corrosion. By implementing these preventive measures, intergranular corrosion in stainless steel sheets can be effectively minimized, ensuring the longevity and performance of the material in various applications.

- Q:What's the thinnest stainless steel plate in China?

- Stainless steel hot rolled plates are rolled into relatively thin steel sheets at higher temperatures, and cold-rolled steel sheets are rolled at room temperature. Usually the first hot rolling, and then cold rolling. If the steel plate is thicker, it can only be rolled by hot rolling, then rolled into a thinner plate and then cold rolled. Hot-rolled steel sheet is divided into thick plate (thickness greater than 4mm) and sheet (thickness of 0.35~4mm) two kinds; cold-rolled steel sheet only (thickness of 0.2~4mm) one.

- Q:What is the specific heat capacity of stainless steel sheets?

- The specific heat capacity of stainless steel sheets may differ based on the specific grade and composition of the stainless steel. Nevertheless, the average specific heat capacity of stainless steel is approximately 500 J/kg°C. Hence, to increase the temperature of one kilogram of stainless steel by 1 degree Celsius, it would necessitate 500 joules of energy. It is crucial to acknowledge that this measurement may not be universally applicable to all varieties of stainless steel. Therefore, it is advisable to seek guidance from specific technical data or reference materials for precise and reliable values.

- Q:How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can start by cleaning the surface thoroughly to remove any dirt or grime. Then, use a stainless steel cleaner or a mixture of mild detergent and warm water to wipe the sheets in the direction of the grain. Next, rinse the sheets with clean water and dry them with a soft cloth. Finally, apply a stainless steel polish or a mixture of vinegar and olive oil to a clean cloth, and gently buff the sheets in circular motions to restore their shine and remove any remaining stains or smudges.

- Q:How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q:Are stainless steel sheets suitable for laser cutting?

- Indeed, laser cutting proves to be a suitable technique for cutting stainless steel sheets. By effortlessly penetrating the material, lasers facilitate the creation of precise and pristine cuts. The elevated heat resistance of stainless steel sheets further renders them ideal for laser cutting, as they endure the intense heat produced by the laser beam. Moreover, owing to their exceptional corrosion resistance, stainless steel sheets enjoy significant popularity across diverse industries. The utilization of laser cutting guarantees minimal distortion and eliminates any physical contact with the material, thereby yielding a finished product of superior quality.

- Q:Are stainless steel sheets resistant to corrosion?

- Yes, stainless steel sheets are generally highly resistant to corrosion due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing the metal from being exposed to corrosive elements and ensuring its durability in various environments.

- Q:Welding defects analysis of 1.5mm stainless steel plate

- Shape defects - the appearance quality is rough; the wave height and width of the fish scales change abruptly; the welding seam and the parent material are not smooth transition.The main reason is improper operation, repair caused.The damage is stress concentration, weakening the carrying capacity.Weld size defectThe size does not conform to the construction drawings or technical requirements.The main reason is the improper operation of the builderHazard: small size, small load cross section;The large size weakens the fatigue strength of some structures subjected to dynamic loads.

- Q:What's the difference between stainless steel hot rolling and cold rolling?

- The difference between hot rolling and cold rolling of stainless steel is that cold rolling is rolled on the basis of hot rolling.

- Q:What's the price of 06cr19ni10 and 304 stainless steel?

- The term "304 stainless steel" comes from the United states. Many people think that "304 stainless steel" is a type of Japanese name, but in strict sense, Japan's 304 stainless steel formal name is "SUS304"". The common marking methods in the market are 06Cr19Ni10304, SUS304, three kinds, in which 06Cr19Ni10 generally means GB standard production, and 304 generally means ASTM standard production, SUS304 mark day standard production.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Sheet Building metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords