Black Diamond Treadmill PVC Conveyor Belt Fitness Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black Diamond Treadmill PVC Conveyor Belt Fitness Belt

1.Product Description:

Our Treadmill conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Easy setting and cleaning, Competitive price and high quality.Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant.

They have different thickness, different patterns, antistatic coating compounds, low noise, long life, high precision, which makes the belts on the treadmill work smoothly and a comfortable running.

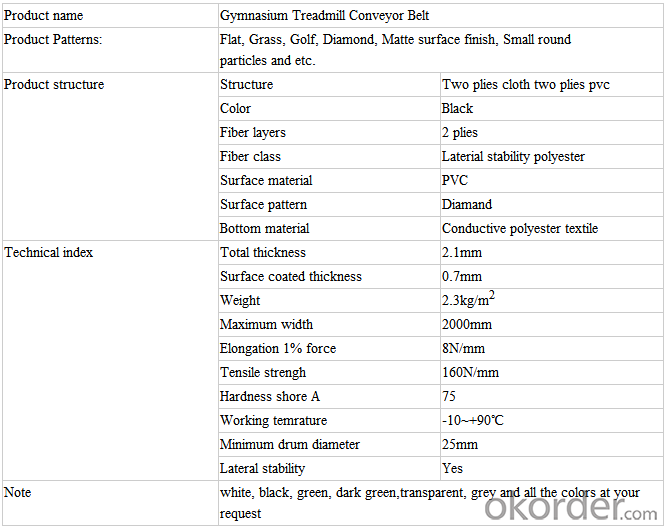

2.Product Specification:

3.Product Advantages:

1).Our treadmill conveyor belts need no lubrication and run quietly and smoothly – without noise or tracking problems.

2).Our treadmill conveyor belts combine low energy sonsuption with durability and an excellent appearance

4.Product Feature:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

5.Product Quality Control

We have very strict quality control system to test all the finished conveyor belts to ensure all the products you receivec are of high quality.

6.Packaging & Shipment

Conveyor belts are packed in rolls and covered by poly woven bags. Also, we can pack it according to your requirments.

7.Product Pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How can rubber products prevent fading?

- For example, footwear product quality inspection process found in the yellowing resistance of some poor performance materials, shallow white soles during the experiment; and meet many enterprises in the production of light, white shoe sole in the process of use and storage in color yellowing phenomenon; even found some enterprises in the production of light, white sole test HG/T3689-2001 "footwear yellowing resistance test method" to determine the material in the approximation of the sun light, ultraviolet radiation resistance to yellowing ability, the observed color change of sample surface degree of occurrence is not large, but the sole is made into shoes in the process of use and storage is prone to yellow phenomenon.

- Q:Excuse me, is PU one kind of silicone? Or what is the connection between the two?

- PU is the abbreviation of Polyurethane, Chinese name is polyurethane, referred to as polyurethane. Because of the simple modification of the formula, different density, elasticity, rigidity and other physical properties can be obtained. At present, a large number of glass fiber insulation materials, wood, traditional rubber products and so on.

- Q:How can the frictional properties of rubber improve?

- The free energy of rubber surface determines the size of the interaction force between rubber and duality, and then affects the adhesive friction of rubber. Generally speaking, the friction coefficient increases with the increase of surface free energy.

- Q:How can rubber and mould not be bonded when producing rubber products?

- When rubber products are made, rubber and mould can not be bonded:1, abrasives to be polished, coating treatment, to achieve the most smooth surface and high temperature corrosion resistance requirements!2, formula design, less use of sticky, easy to corrosive materials;3, curing process should meet the requirements of formula design!

- Q:What is the composition of the vulcanizing agent for silica gel?

- Any material that can undergo vulcanization or cross linking with rubber is collectively referred to as a vulcanizing agent, also known as a crosslinker.Many kinds of curing agents, and growing, curing agent has been used with sulfur, selenium, tellurium, sulfur compounds, metal oxides, peroxides, resin, quinone and amine etc..

- Q:What is the cause of the bursting of rubber products and how should they be improved?

- Improvement measures: 1.. Adjust the molding sulfuration temperature, adjust the temperature of the upper and lower plate. 2. adjust the exhaust distance and exhaust time. 3. in strict accordance with the mixing process standards or adjust the formula and mixing process, avoid the use of time is too long to place material (fast cooked). 4., in the explosive edge position plus running trough. 5. control the weight of a single adhesive.

- Q:Will the rubber ring of the thermos bottle be harmful to the human body?

- In order to ensure drinking water hygiene, thermos bottle rubber gasket should adopt silicon rubber chemical stability and good resistance to aging, agent should choose to comply with food hygiene requirements. If the material with other rubber as raw material, should pay attention to food hygiene requirements.

- Q:Rubber products labeled Huai gum can improve wear?

- In accordance with the requirements of the inquiry, the tire carbon black is a special production, usually oil to produce, mainly in the heavy oil products, coal, coal tar and other raw materials as a result of incomplete combustion

- Q:How to remove the rubber front?

- The other is the freeze trimming method. Is a use of ultra low temperature makes the rubber and plastics flash rapid embrittlement of liquid nitrogen, and in this state, the flash frozen particles of high-speed jet impact products (fash), which not only can flash with high quality and high efficiency removal of rubber products (fash) and keep the special trimming equipment of all plastic products itself does not change. D shell Ba Quan?? especially in Japan, in the basic use of frozen trimming.

- Q:What kind of material does the shockproof rubber cushion usually choose? What's the hardness?

- Recommend the use of EPDM, its good elasticity, although lower than natural rubber, isoprene rubber and butadiene rubber but its resistance to aging, corrosion resistance, chemical resistance, resistance to high pressure steam performance advantage, so compared to choose EPDM.Shock absorbing rubber used to be the only adhesive for NR in the past. In recent years, in order to meet the requirements of increasing heat resistance and oil resistance of automobiles, IIR, EPDM, NBR and CR have also begun to be used, and even microcellular PU elastomers and TPE thermoplastic elastomers have appeared. In addition, according to automotive requirements, in order to achieve lightweight targets, plastics have begun to replace metal, so-called rubber and plastic shock absorption rubber products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Diamond Treadmill PVC Conveyor Belt Fitness Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords