Black Crescent Pattern PVC/PVK Logistics Industry Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black Crescent Pattern PVC/PVK Logistics Industry Conveyor Belt

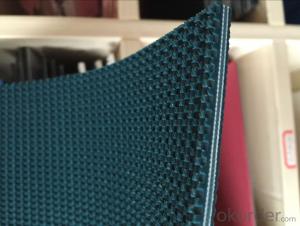

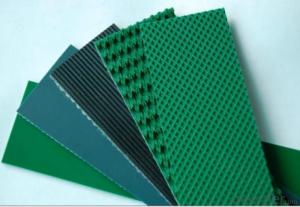

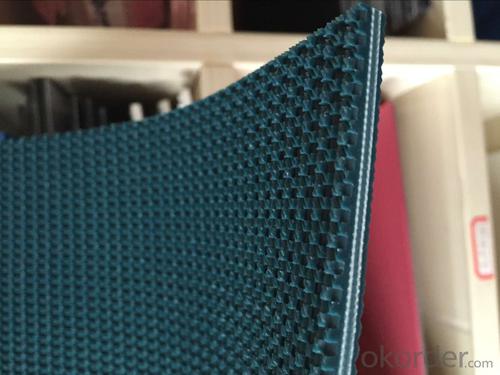

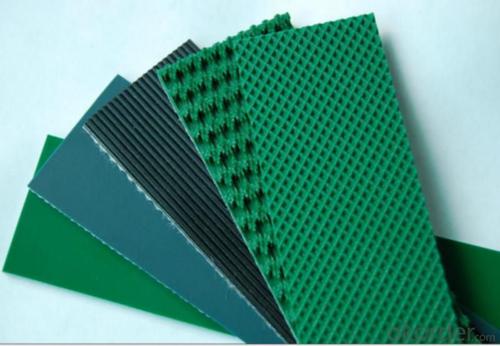

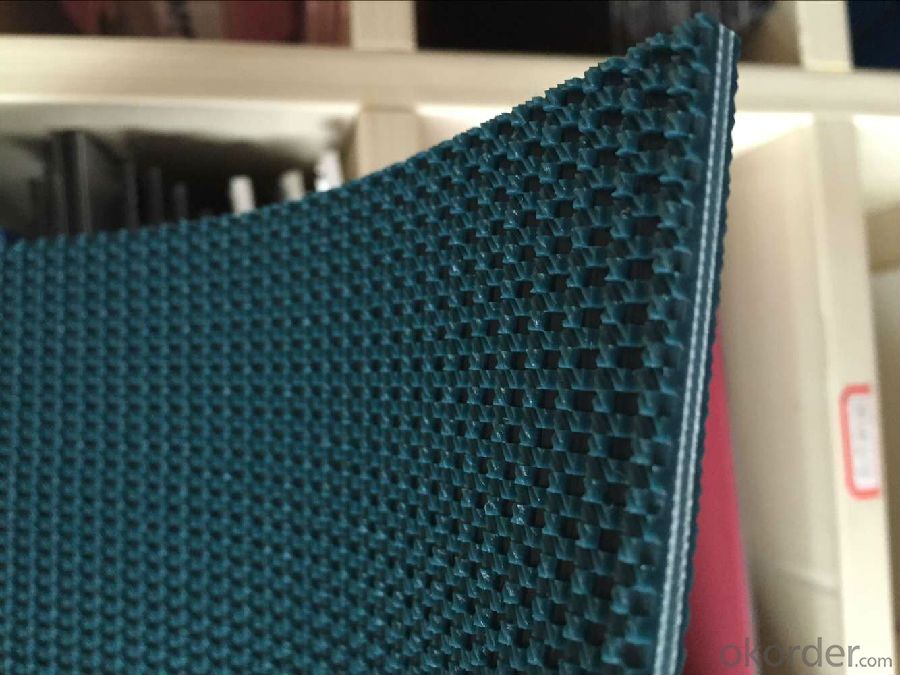

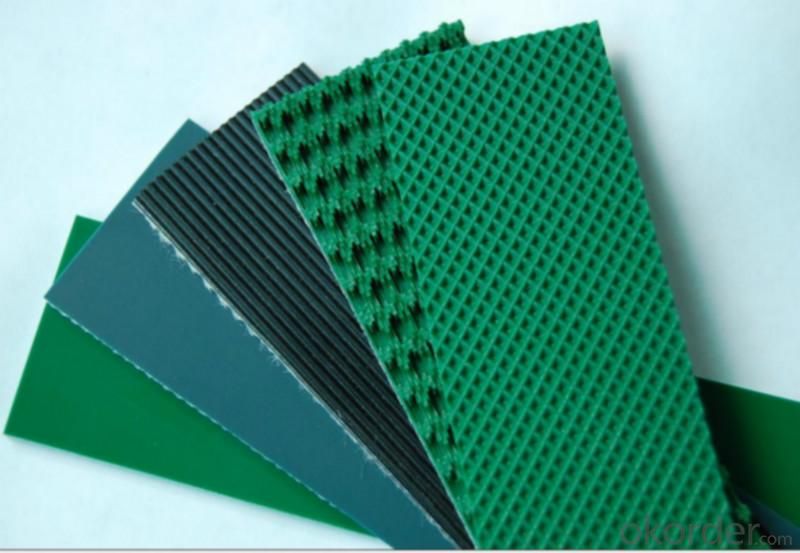

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

The main products include flat surface series, anti-slid series which diversified in a lot of textures for meeting different conveying conditions and environment, featuring anti-static, anti-corrosion, flame retardant etc.

There are wide range of patterns of rough top belt available including Diamond, Chevron, Herringbone, Rib, Grid, Wave, Round and Oval nubs, Convex-tooth etc.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Product Photos

For more informations,please contact us freely,thank you.

- Q: What are the advantages and disadvantages of plastic packaging materials?

- Secondly, the plastic material has a very suitable barrier and permeability, you know, in plastic packaging, there is gas barrier packaging. Moisture proof packaging, waterproof packaging, and all kinds of fresh fruit packaging. These are plastic packaging to meet the respiratory effects of fresh ingredients. Again, the optical properties of plastic packaging is very good, because the plastic packaging materials can be made transparent, so when it is made of packaging containers, for which we see the contents of the indirect effect of crystal clear, very good promotion way.

- Q: Electric kettle is plastic, okay?

- In addition, plastic electric kettle, only the outer shell is made of plastic, the liner is used in stainless steel, but the electric kettle in the heating process, the stainless steel liner temperature will become very high, the external plastic shell may appear a little taste in the heat, but this kind of the taste is very slight, generally do not produce what harm to the human body.

- Q: How do you prevent olive nets from damaging the branches or leaves of the olive trees?

- To prevent olive nets from damaging the branches or leaves of the olive trees, it is essential to ensure proper installation and maintenance. Firstly, the nets should be securely attached to the tree trunks or stakes, ensuring they are tightly stretched over the tree canopy. This prevents any excessive movement or rubbing against the branches. Additionally, regular inspection and adjustment of the nets are crucial to address any potential damage caused by wind or other factors. By taking these precautionary measures, olive nets can effectively protect the fruit while minimizing harm to the branches and leaves of the olive trees.

- Q: What are the processing methods of black masterbatch and what is more prominent than other plastic raw materials?

- In addition, carbon black has a special contribution to the strength of products and the enhancement of conductivity. There are three types of information plates available in the Fu plastics website: single screw, double screw, and dense. Single screw method, using mixing machine materials after mixing by single screw extruder brace granulation, the carbon concentration in the general 18-20%, production process backward, poor environmental conditions, is eliminated by process, do not rule out some fledgling small factories still use the method of processing.

- Q: Can olive nets be used in olive groves with limited space for storage?

- Yes, olive nets can be used in olive groves with limited space for storage. Olive nets are lightweight and flexible, making them easy to install and remove as needed. They can be folded or rolled up for compact storage, allowing olive grove owners with limited space to store them conveniently.

- Q: How do olive nets prevent damage from hailstorms?

- Olive nets prevent damage from hailstorms by acting as a physical barrier that shields the olive trees from the impact of hailstones. The nets are designed to absorb the force of the hailstones, preventing them from directly hitting the trees and causing damage to the branches, leaves, or fruits. Additionally, the nets also help in reducing the velocity of the hailstones, further minimizing the chances of damage.

- Q: Are olive nets resistant to mold and mildew?

- Yes, olive nets are generally resistant to mold and mildew due to the materials they are made of, such as high-density polyethylene (HDPE), which is known for its resistance to moisture and fungal growth.

- Q: Are olive nets easy to transport?

- Yes, olive nets are easy to transport due to their lightweight and foldable design.

- Q: Can olive nets be used on trees with a small trunk?

- Yes, olive nets can be used on trees with a small trunk. Olive nets are designed to protect the olives from birds and other pests, regardless of the size of the tree trunk. They can be easily draped over small trees and secured to prevent any damage to the olives.

- Q: Plastic products in the injection process should pay attention to what?

- When the material is formed, the molten material contacts the cavity surface and the outer layer is cooled immediately to form a low density solid shell. Because of the poor thermal conductivity of plastic, the inner part of the plastic part is cooled slowly to form a large solid layer with high density. Therefore, the wall thickness, cooling slow, high-density layer thickness is large contraction. In addition, the layout and number of inserts have direct influence on the direction of material flow, the density distribution and the shrinkage resistance. Therefore, the characteristics of plastic parts have great influence on the shrinkage size and direction.

Send your message to us

Black Crescent Pattern PVC/PVK Logistics Industry Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords