Big Diameter PVC Pipe Extrusion / Prodcution Line With 10 Years Experience Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

This PVC pipe production line is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The PVC pipe production line has conical twin-screw extruder, vacuum sizing box, traction machine, cutting machine, stacker frame and so on, Extruder, vacuum shaped tank, and haul-off machine motor produce high-quality products, haul-off machine have two-claw, three claw, and four claw, six claw, the cutter use knife-raised cutter or planetary cutter. And the stacker take into account length.

Characteristic

Pipe range | 20-63mm single | 20-63mm dual | 75-160mm | 110-315mm | 315-630mm |

Extruder | CMAX51/105 | CMAX65/132 | CMAX80/156 | CMAX80/156 | CMAX92/188 |

Extruder power | 18.5kw | 37kw | 37kw | 55kw | 110kw |

Extrusion capacity | 120kg/h | 250kg/h | 250kg/h | 360kg/h | 800kg/h |

Max. Production speed | 12m/min | 10m/min | 6 m/min | 3 m/min | 1.2m/min |

Process flow

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator →

vacuum forming machine → haul off machine → cutting machine → discharging rack

Capacity: Conical twin-screw extruder, suitable for process PVC powder with high capacity, max 1000kg/h

Diameter: from 16mm to 800mm

Auxiliary machine closely meet customer specifications. Nice out-look, automatic control and stable running performance

Application

PVC pipe is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The lines have conical twin-screw extruder, vacuum calibration tank, haul-off machine, cutting machine, stacker or belling machine and so on. Haul-off machine have two caterpillar, three caterpillar, and four caterpillar, six caterpillar, the cutter use knife-raised cutter or planetary cutter which support chamferring function. And the stacker take into account length, production line is reliable performance, and high quality, we have exported to Egypt, Brazil, Syria, Uzbekistan etc.

Features

1) Main machine uses PVC twin screw, and notch feeder with powerful water

cover cooler, which has greatly improved transmitting capability and ensured

extruding.

2) Adopting double pipe extrusion method, it can greatly increase productivity.

3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paint

cooler gullet, which improve the finished product passing rate, and meet

the requirements of high speed manufacturing. Vacuum calibrating platform and cooler

gullet are all made of stainless steel

4) Adopting multi-caterpillar haul-off, through the central motor to run all the caterpillar

to reach same height, and ensure roundness of pipes

5) Adopting fully automatic control system with high precision, reliable operation,

easy and convenient handling

6) Suitable pipe diameter: 20 - 630mm

System configuration:

(a) Feeding machine

(b) Conical twin-screw extruder

(c) Mould

(d) Vacuum calibrating tank

(e) Hauling off machine

(f) Printing machine

(g) Pipe cutting machine

(h) Pipe pile-up frame

(i) Auxiliary machine such as mixer, water chiller, belling machine and crushing machine.

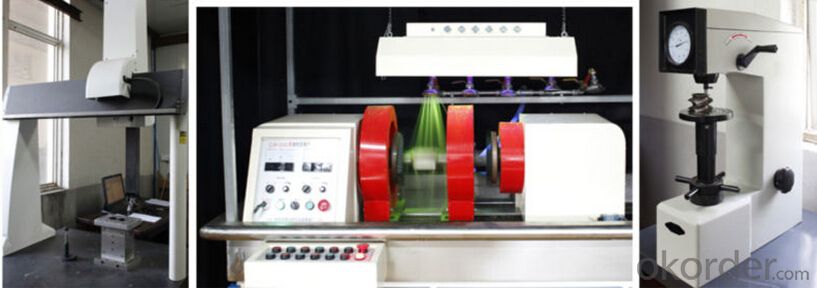

Product show

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting. Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q: Why single screw extruder is controlled by high school and low?

- What is controlled by high school? I can't answer the question without saying it

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q: Extrusion machine operating procedures, specific points, thank you!

- 1, operators must be familiar with the procedures, the safety test qualified, wear good protective equipment, shall operate the equipment.2 when the power is on, check whether the thermal control of the electric appliance is sensitive and reliable, whether the thermocouple indicates the temperature is correct or not, and if there is a problem, please repair the personnel to exclude them.3 when driving, should check the main reducer, traction non polar transmission, the line is stepless gear box lubrication is normal, fan ventilation is good.4 before driving, pay attention to the heating temperature of each section, whether the actual temperature required by the process, the heat preservation time should be enough, and the initial heating time can not be less than 3 hours heat preservation.5, not in the plastic bad, scorched, aging, extrusion production, in case of accidents, and found the above problems, immediately try to rule out.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat, because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: Is the extruder the same as the extruder?

- The extruder is also called in the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

Big Diameter PVC Pipe Extrusion / Prodcution Line With 10 Years Experience Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches