Bearings single row tapered roller 32048

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

- Single row Tapered roller bearings

Single row roller bearings can only bear the shaft or shell of a direction of the axial

displacement and a direction of the axial load. So we need the two bearing face to face or

back to back to use.

★Product features

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the

raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing. The rollers are guided by a

flange on the inner ring. This stops the rollers from sliding out at high speed due to their momentum. The larger the half angles of these

cones the larger the axial force that the bearing can sustain.

★Product application

In many applications tapered roller bearings are used in back-to-back pairs so that axial

forces can be supported equally in either direction.

Pairs of tapered roller bearings are used in:

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

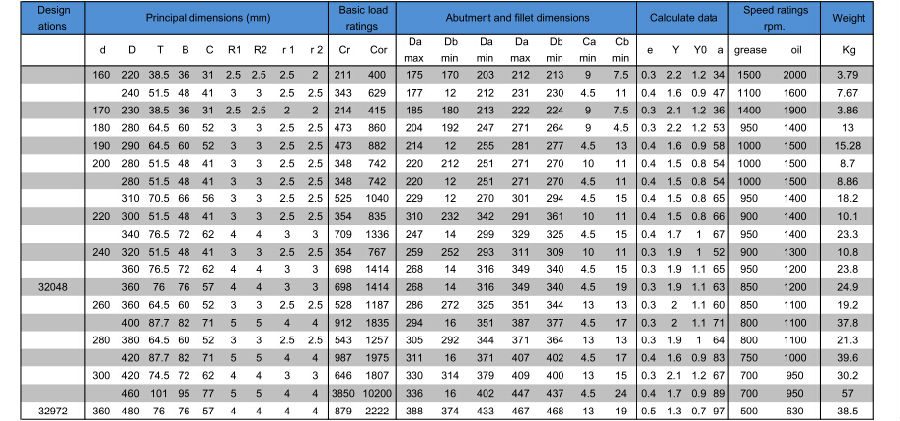

★Horton tapered roller bearings Basic size

- Single row tapered roller bearings:

Inner ring size: 20mm ~ 1270mm Outer ring size: 40mm ~ 1460mm Width size: 15mm ~ 240mm

- Double row tapered roller bearings:

Inner ring size: 38mm ~ 1560mm Outer ring size: 70mm ~ 1800mm Width size: 50mm ~ 460mm

- Four row tapered roller bearings:

Inner ring size: 130mm ~ 1600mm Outer ring size: 200mm ~ 2000mm Width size: 510mm ~ 1150mm

★Tolerance:

Horton tapered roller bearing with common

tolerance, and also provides P6X, P6, P5, P4,

★Radial clearance

Horton single row tapered roller bearings only

in after installation have clearance, and in

★Cage

Tapered roller bearing general ues the steel plate stamping, basket shape cage, but when the size is bigger, we

also adopts entity cage.

1. Outside diameter D ≤ 650mm, use the steel plate stamping cage, cage postposition without code mark.

2. Outside diameter D > 650 mm, use the steel entity prop cage, cage postposition without code mark.

★Dynamic equivalent load

P = Fr [KN], Fa / Fr ≤ e;

P = 0.4Fr + YFa [KN], Fa / Fr > e.

The single row tapered roller bearings used in pairs (basic physical size can be different), when calculation the

equivalent dynamic load of the bearing, must be included in the radial load cause additional axial force. The single

row tapered roller bearing additional axial force S, can approximate formula: S = Fr / 2y

★Static equivalent load

Single row tapered roller bearings

P0 = 0.5Fr + Y0Fa [KN] P0 < Fr, then P0 = Fr

Double row tapered roller bearings

P = 0Fr + Y1Fa [KN],Fa/Fre ≤e P = 0.67Fr + Y2Fa [KN], Fa/Fre > e

- Q: Taper roller bearings are used on my motor. Serious damage occurred during use. Please help me analyze the possible causes of damage! Thank you

- To LZ: 1 it is recommended that the radial force and the rated load of the bearing be compared to determine whether the radial force is too large (if there is axial force, it needs to be synthesized as equivalent load, and then compare.) In 2 section, you basically is the middle of the two row tapered bearing ring and then as a double row tapered to use (not in general, so natural clearance installed back to back) without gasket or nut to adjust, this is a very good idea.

- Q: What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

- Q: Is the tapered roller bearing so correct?

- For example, the middle roller you draw is cylindrical, and the roller of the tapered roller bearing is a frustum of a cone

- Q: How does the roller of tapered roller bearings fit in?

- Tapered roller bearings are made up of outer rings, inner rings, rollers, and cages. The outer ring is a single body, and the inner ring, roller and cage are assembled together. They are called inner components. Tapered roller bearings belong to separable bearings, and when installed, the two components (inner and outer rings) can be fitted together.

- Q: There is a slot in the inner ring of tapered roller bearings, right? Is the roller in the slot?

- Yes.AskIs there a gap between the roller and the slot when the roller is placed in the slot?Chasing the answerNo

- Q: What items should be inspected for tapered bearings?

- 2, tapered roller bearings are not allowed to have an electric drill pattern, vibration patterns, yin and Yang face and polished traces, did not promise to emerge supporting construction and obvious measurement traces, did not agree to knock bumps and obvious color difference.3, the name of the whole machine did not promise to have oxide skin.

- Q: Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.So, we use bearing technology or design personnel, only need to control your speed in the following catalog bearing manufacturers can.In addition, oil lubrication is better than grease lubrication at the same speed.

- Q: Online cylinder cones are GB/T4663, what do you mean?

- Which size do you want, eldest brother? How do I make so much?GB/T: recommended national standards; GB: mandatory national standards4663: taper roller national standard codeThere is a missing release year later!It should be: GB/T 4663-1994

- Q: that is to say, the taper head is the face and the back is the back

- The installation of tapered roller bearings is not only to pay attention to the direction of installation, there are many other places to pay attention to, is a very professional technical activities

- Q: What are the general uses of tapered roller bearings?

- Micro car owners differential speedMain reducing wheel hub of light truckMain reducing wheel hub for heavy truck

Send your message to us

Bearings single row tapered roller 32048

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords