Bearing Steel Rod 52100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Steel Grade: | Standard: | Dimensions: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Technique: | Application: | Alloy Or Not: | |||

| Special Use: | Type: | Grade: | |||

| Surface treatment: | Delivery condition: | Main products: | |||

| Trade term: |

Packaging & Delivery

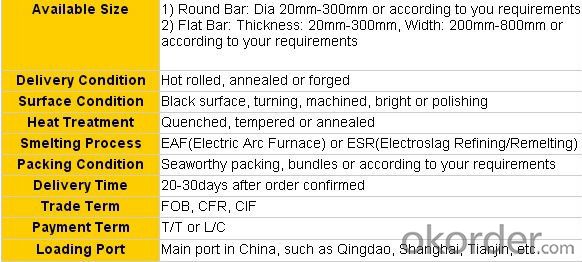

| Packaging Detail: | GCr15 bearing steel: Seaworthy package or according to buyers' requirement |

| Delivery Detail: | 30days |

Specifications

Bearing Steel Rod 52100

1)Competitive price

2)High chromium bearing steel

3)ISO 9001:2008 and SGS

Bearing Steel Rod 52100

Steel Material: ASTM 52100,JIS SUJ2,BS100Cr6, GB GCr15 high-carbon chromium bearing steel

Similar or Equivalent Grades

GB | AISI | ISO | JIS |

GCr15 | 52100 | 100Cr6 | SUJ2 |

Chemical composition

Mechanical Property

Delivery State | |

Brinell Hardness HBS | Impression Diameter /mm |

179-207 | 4.2-4.5 |

Characteristics

1) Good hardability and high toughness

2) Long fatigue life

3) Medium cold processing plasticity

4) Certain machinability

5) Poor weldability

Application

1) Steel ball, roller and collar of large machinery bearing

2) High-hardness and high contact fatigue strength machinery parts with heavy load, such as axis of rotation, blade, stator pump, profiling, sleeve, mandril, etc.

Description Details

- Q: What are the different methods of surface hardening for special steel?

- There are several methods of surface hardening for special steel, including carburizing, nitriding, induction hardening, flame hardening, and laser hardening.

- Q: How does special steel perform in forging applications?

- Special steel is highly regarded in forging applications due to its exceptional strength, durability, and resistance to wear and tear. The unique properties of special steel, such as high tensile strength, heat resistance, and corrosion resistance, make it an ideal choice for withstanding the extreme conditions involved in forging processes. When subjected to the intense heat and pressure of forging, special steel maintains its structural integrity and mechanical properties. It can withstand the extreme temperature fluctuations without losing its hardness or becoming brittle, ensuring that the final forged product is of high quality and reliability. Furthermore, special steel offers excellent machinability and formability, allowing it to be easily shaped and manipulated during the forging process. This ease of working with special steel enables manufacturers to create intricate and complex shapes, resulting in finely crafted forged components. Special steel also exhibits superior resistance to fatigue and impact, making it highly suitable for applications that require high strength and toughness. It can withstand repeated stress and load cycles without experiencing significant deformation or failure, ensuring the longevity and reliability of forged products. In addition, special steel is known for its resistance to corrosion and oxidation, which further enhances its suitability for forging applications. It can withstand exposure to harsh environments, chemicals, and moisture, making it ideal for manufacturing components that are subjected to demanding operating conditions. Overall, special steel's exceptional performance in forging applications can be attributed to its high strength, durability, resistance to wear and tear, excellent machinability, and corrosion resistance. These properties make it a preferred choice in various industries, including automotive, aerospace, construction, and oil and gas, where high-quality forged components are essential for reliable and efficient operations.

- Q: How does special steel contribute to improving product lifespan?

- Special steel contributes to improving product lifespan by offering enhanced strength, durability, and resistance to corrosion. Its unique composition and manufacturing processes result in a material that can withstand harsh conditions, heavy loads, and wear and tear over an extended period. This increased longevity and reliability of products made with special steel ultimately leads to reduced maintenance costs, less frequent replacements, and improved customer satisfaction.

- Q: Can special steel be used in the railway industry?

- Yes, special steel can be used in the railway industry. Special steel, such as high-strength steel or corrosion-resistant steel, can be utilized for various applications in the railway industry, including the construction of tracks, bridges, and locomotives. These types of steel offer enhanced durability, strength, and resistance to wear and tear, making them suitable for the demanding conditions and heavy loads encountered in the railway sector.

- Q: How does maraging steel achieve high strength through aging?

- Maraging steel achieves high strength through aging by undergoing a process called precipitation hardening. This involves heating the steel to a specific temperature and holding it there for a certain period of time, followed by rapid cooling. This process allows the formation of fine, intermetallic particles within the steel's microstructure, which greatly enhances its strength. Additionally, the aging process helps relieve residual stresses and improves the steel's toughness and corrosion resistance.

- Q: How is the tensile strength of special steel measured?

- The tensile strength of special steel is typically measured using a standardized test called a tensile test. In this test, a sample of the steel is subjected to controlled tensile forces until it reaches its breaking point. The amount of force required to break the sample is then recorded as the tensile strength of the steel.

- Q: How does special steel contribute to the defense and security industry?

- Enhanced strength, durability, and resistance to extreme conditions are crucial attributes of special steel, playing a vital role in the defense and security industry. This type of steel is specifically designed to meet the industry's unique demands, ensuring military equipment and infrastructure can withstand challenging environments and threats. One significant contribution of special steel to the defense and security sector lies in its use for manufacturing armored vehicles and tanks. These vehicles require high-strength steel to protect military personnel from ballistic and explosive threats. Special steel provides the necessary toughness and resilience to withstand impacts, ensuring soldiers' safety on the battlefield. Moreover, special steel is instrumental in the production of naval vessels and submarines. The maritime environment poses significant challenges due to its corrosive nature and harsh weather conditions. By utilizing special steel, naval ships can be constructed with superior corrosion resistance, extending their lifespan and reducing maintenance costs. Additionally, special steel is vital for the production of military-grade weaponry and ammunition. The steel's high strength and durability ensure that firearms, missiles, and other weapons can withstand extreme forces and function reliably in critical situations. This reliability is of utmost importance in the defense and security industry, where weapon failure could have severe consequences. Furthermore, special steel contributes to the construction of critical defense infrastructure, including military bases, bunkers, and communication towers. Its ability to withstand extreme temperatures, high pressures, and other challenging conditions ensures the reliability and longevity of these structures, enhancing national security. In summary, special steel's unique properties, including high strength, durability, and resistance to extreme conditions, are essential in the defense and security industry. By incorporating this material into military equipment, vehicles, weaponry, and infrastructure, defense organizations can ensure the safety, reliability, and effectiveness of their operations, ultimately contributing to national security.

- Q: Can special steel be used for making nuclear industry components?

- Yes, special steel can be used for making nuclear industry components. Special steel, also known as stainless steel, possesses excellent corrosion resistance, high strength, and heat resistance properties, making it suitable for various applications in the nuclear industry. It is commonly used for manufacturing reactor vessels, steam generators, fuel cladding, and other critical components that require durability and reliability in nuclear power plants.

- Q: What are the properties of high-strength alloy steel?

- High-strength alloy steel possesses several important properties, including exceptional strength, hardness, and wear resistance. It also exhibits excellent toughness, allowing it to withstand high-stress applications without fracturing or deforming. Additionally, this type of steel often maintains its mechanical properties even at elevated temperatures, making it suitable for use in extreme environments. Finally, high-strength alloy steel typically offers good corrosion resistance, which allows it to withstand exposure to various chemicals and harsh conditions.

- Q: What are the different surface protection methods for special steel?

- There are several surface protection methods for special steel, including galvanization, coating with protective paints or varnishes, electroplating, and applying corrosion-resistant alloys or metals. These methods help prevent rust, corrosion, and other forms of damage, ensuring the longevity and durability of the special steel.

Send your message to us

Bearing Steel Rod 52100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords