ASTM Standard Checker Five Bar Painted Aluminum Sheets in Shreveport

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

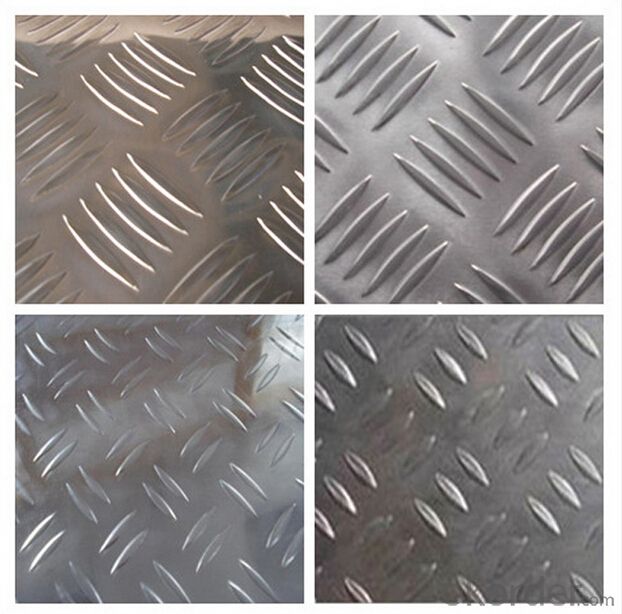

1.Structure of ASTM Standard Checker Five Bar Aluminum Tread Plate Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of ASTM Standard Checker Five Bar Aluminum Tread Plate :

1). Aircraft, automobile, train

2). Building wall, ceilings, roofing, furniture cabinet, lighting plate

3). Shipping plate, solar reflective plate,Corner protector, insulation material

4). Beverage bottle, cap, ring-pull, cosmetics shell and cover

5). Aluminum tread/embossed plate, quenched and pre-stretched plate

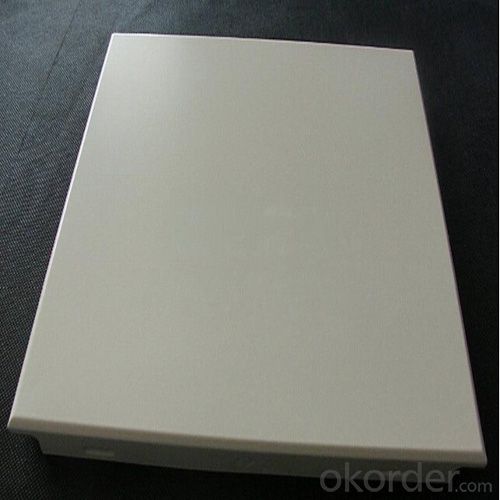

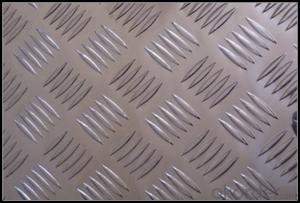

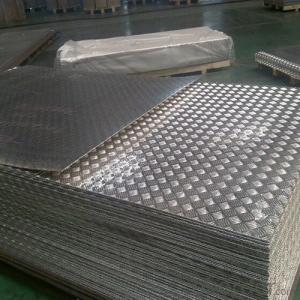

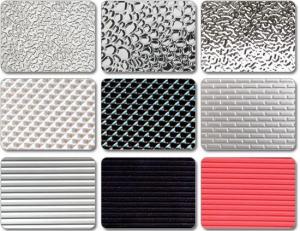

3. ASTM Standard Checker Five Bar Aluminum Tread Plate Images:

4. ASTM Standard Checker Five Bar Aluminum Tread Plate Specification:

embossing Aluminum Tread Sheet | |

Alloy | 1100,1060, 3003, 5005 5052 |

Temper | H14,H18,H24,H32 |

Thickness (mm) | 1.5mm to 6mm |

Width (mm) | Up to 1500mm |

Length (mm) | Up to 6000mm |

Standard | EN standard ASTM standard |

MOQ | 5ton |

Application | 1)Decorated inside and outside the car /building frame, windows, doors, ceiling, decorating panel and curtain wall 2)Household appliances: refrigerators, microwave ovens, audio equipment, etc. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is aluminium oxide sheet?

- The aluminum oxide plate is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is carried out under certain conditions and applied current. Anodized aluminum plate on the surface of the formation of alumina thin layer, its thickness is 5~20 microns, hard anodized film up to 60~200 microns.

- Q: What are the different methods of surface printing aluminum sheets?

- Some of the different methods of surface printing aluminum sheets include screen printing, offset printing, digital printing, and engraving.

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- Types Of Aluminum

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Yes, aluminum sheets are suitable for manufacturing architectural ceiling panels. Aluminum is known for its durability, lightweight nature, and resistance to corrosion, making it an ideal material for architectural applications. It can be easily shaped and formed into various panel designs and sizes, offering flexibility in creating unique ceiling designs. Additionally, aluminum sheets are available in different finishes and colors, allowing for customization to meet specific design requirements. Overall, aluminum sheets provide a cost-effective and aesthetically pleasing solution for manufacturing architectural ceiling panels.

- Q: Are aluminum sheets resistant to vibration?

- Aluminum sheets, in general, demonstrate resistance towards vibration. Being a lightweight and flexible material, aluminum possesses excellent damping characteristics, enabling it to effectively absorb and dissipate vibrations. Moreover, aluminum exhibits a high strength-to-weight ratio, ensuring its structural integrity remains intact under vibrating conditions. Consequently, aluminum sheets are highly favored in sectors like aerospace, automotive, and construction, where protection against vibrations is crucial. Nevertheless, it is important to acknowledge that the degree of vibration resistance may differ depending on various factors such as the thickness and alloy composition of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: Are aluminum sheets suitable for insulation purposes?

- Yes, aluminum sheets are suitable for insulation purposes. Aluminum is a highly reflective material that can effectively block the transfer of heat, making it an excellent choice for insulation. It has a low emissivity value, meaning that it reflects heat radiation rather than absorbing it. This property helps to maintain a consistent temperature within a space, reducing the need for heating or cooling. Additionally, aluminum sheets are lightweight, easy to install, and resistant to moisture, making them a practical option for insulation in various applications such as attics, walls, floors, and HVAC systems.

- Q: Are aluminum sheets suitable for automotive heat shields?

- Certainly! Automotive heat shields can indeed utilize aluminum sheets. Aluminum is an exceptional option for heat management in automotive applications due to its lightweight nature and impressive conductivity. Its high melting point and excellent thermal conductivity properties allow it to efficiently absorb and disperse heat produced by the vehicle's engine, exhaust system, and other heat sources. Furthermore, aluminum sheets are easily moldable and can be crafted into diverse sizes and designs, making them adaptable for various automotive heat shield purposes. In summary, aluminum sheets offer an economical and effective means of safeguarding vulnerable components from heat-related harm within automotive systems.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

ASTM Standard Checker Five Bar Painted Aluminum Sheets in Shreveport

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords