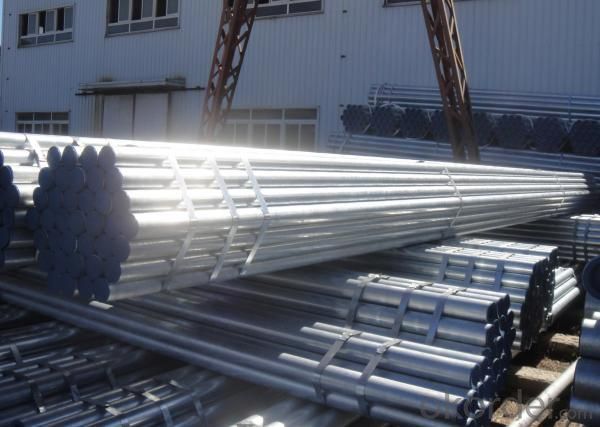

ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe:

All the products supplied by us should be produced strictly according to the standards, such as ASTM A53, GB/T9711, API 5L, GB/3091, ASTM A500 and some other domestic and international standards to satisfy your various requirements, which is widely applied to the industries of construction, steel structure, natural gas, shipbuilding, chemical, boiler and other relative fields.

It is widely used in building, machine, chemical equipment, automobile industrial, container, it is also applied to agriculture and mine machine.

Standard:ASTM A53,BS1387,GB3091

Steel grade: ASTM A53: A, B, C GB3091, BS1387:Q195,Q215,Q235

Thickness of zinc coating: 100g/m2, 120g/m2, 150g/m2, 200g/m2, 250g/m2, 300g/m2, 350g/m2. 400g/m2

Size of ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe:

OD(MM)

WT(MM) |

21.3 |

26.7 |

33.4 |

42.2 |

48.3 |

60.3 |

73 |

88.9 |

114.3 |

141.3 |

168.3 |

219.1 |

1.70 |

|

|

|

|

|

|

|

|

|

|

|

|

1.80 |

|

|

|

|

|

|

|

|

|

|

|

|

1.90 |

|

|

|

|

|

|

|

|

|

|

|

|

2.00 |

|

|

|

|

|

|

|

|

|

|

|

|

2.10 |

|

|

|

|

|

|

|

|

|

|

|

|

2.20 |

|

|

|

|

|

|

|

|

|

|

|

|

2.30 |

|

|

|

|

|

|

|

|

|

|

|

|

2.40 |

|

|

|

|

|

|

|

|

|

|

|

|

2.50 |

|

|

|

|

|

|

|

|

|

|

|

|

2.75 |

|

|

|

|

|

|

|

|

|

|

|

|

3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

3.25 |

|

|

|

|

|

|

|

|

|

|

|

|

3.50 |

|

|

|

|

|

|

|

|

|

|

|

|

3.75 |

|

|

|

|

|

|

|

|

|

|

|

|

4.00 |

|

|

|

|

|

|

|

|

|

|

|

|

4.25 |

|

|

|

|

|

|

|

|

|

|

|

|

4.50 |

|

|

|

|

|

|

|

|

|

|

|

|

4.75 |

|

|

|

|

|

|

|

|

|

|

|

|

5.00 |

|

|

|

|

|

|

|

|

|

|

|

|

5.25 |

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A53

ASTM A53 LIGHT ( HOT DIPPED GALVANIZED PIPES) | ||||||||||||||||

SIZE |

Max |

Min |

Wall Thickness |

Bare Pipes Weight |

Screwed &

Socketed Pipes

Weight | |||||||||||

INCH |

NB(MM) |

mm |

mm |

mm |

kg/m |

kg/m | ||||||||||

1/2" |

15 |

21.4 |

21 |

2 |

0.947 |

0.956 | ||||||||||

3/4" |

20 |

26.9 |

26.4 |

2.3 |

1.38 |

1.39 | ||||||||||

1" |

25 |

33.8 |

33.2 |

2.6 |

1.98 |

2 | ||||||||||

1-1/4" |

32 |

42.5 |

41.9 |

2.6 |

2.54 |

2.57 | ||||||||||

1-1/2" |

40 |

48.4 |

47.8 |

2.9 |

3.23 |

3.27 | ||||||||||

2" |

50 |

60.2 |

59.6 |

2.9 |

4.08 |

4.15 | ||||||||||

2-1/2" |

65 |

76 |

75.2 |

3.2 |

5.71 |

5.83 | ||||||||||

3" |

80 |

88.7 |

87.9 |

3.2 |

6.72 |

6.39 | ||||||||||

3-1/2" |

90 |

113.9 |

113 |

3.6 |

9.75 |

10 | ||||||||||

ASTM A53 MEDIUME ( HOT DIPPED GALVANIZED PIPES) | ||||||||||||||||

SIZE |

Max |

Min |

Wall Thickness |

Bare Pipes Weight |

Screwed &

Socketed

Pipes Weight | |||||||||||

INCH |

NB(MM) |

mm |

mm |

mm |

kg/m |

kg/m | ||||||||||

1/2" |

15 |

21.7 |

21.1 |

2.6 |

1.21 |

1.22 | ||||||||||

3/4" |

20 |

27.2 |

26.6 |

2.6 |

1.54 |

1.57 | ||||||||||

1" |

25 |

34.2 |

33.4 |

3.2 |

2.41 |

2.43 | ||||||||||

1-1/4" |

32 |

42.9 |

42.1 |

3.2 |

3.1 |

3.13 | ||||||||||

1-1/2" |

40 |

48.9 |

48.3 |

3.2 |

3.57 |

3.61 | ||||||||||

2" |

50 |

60.8 |

59.9 |

3.6 |

5.03 |

5.1 | ||||||||||

2-1/2" |

65 |

76.6 |

75.4 |

3.6 |

5.43 |

6.55 | ||||||||||

3" |

80 |

89.5 |

88.1 |

4.5 |

8.37 |

8.54 | ||||||||||

4" |

100 |

114.9 |

113.3 |

4.5 |

12.2 |

12.5 | ||||||||||

5" |

125 |

140.6 |

138.7 |

5 |

15.6 |

17.1 | ||||||||||

6" |

150 |

166.1 |

164.1 |

5 |

19.7 |

20.3 | ||||||||||

ASTM A53 HEAVY ( HOT DIPPED GALVANIZED PIPES) | ||||||||||||||||

SIZE |

Max |

Min |

Wall Thickness |

Bare Pipes Weight |

Screwed &

Socketed

Pipes Weight | |||||||||||

INCH |

NB(MM) |

mm |

mm |

mm |

kg/m |

kg/m | ||||||||||

1/2" |

15 |

21.7 |

21.1 |

3.2 |

1.44 |

1.45 | ||||||||||

3/4" |

20 |

27.2 |

26.6 |

3.2 |

1.87 |

1.88 | ||||||||||

1" |

25 |

34.2 |

33.4 |

4 |

2.94 |

2.96 | ||||||||||

1-1/4" |

32 |

42.9 |

42.1 |

4 |

3.8 |

3.83 | ||||||||||

1-1/2" |

40 |

48.9 |

48.3 |

4 |

4.38 |

4.42 | ||||||||||

2" |

50 |

60.8 |

59.9 |

4.5 |

5.19 |

5.26 | ||||||||||

2-1/2" |

65 |

76.6 |

75.4 |

4.5 |

7.93 |

8.05 | ||||||||||

3" |

80 |

89.5 |

88.1 |

5 |

10.3 |

10.5 | ||||||||||

4" |

100 |

114.9 |

113.3 |

5.4 |

14.5 |

14.9 | ||||||||||

5" |

125 |

140.6 |

138.7 |

5.4 |

17.9 |

18.4 | ||||||||||

6" |

150 |

166.1 |

164.1 |

5.4 |

21.3 |

22.9 | ||||||||||

- Q: How do you repair damaged steel pipes?

- To fix steel pipes that have been damaged, there are several steps you can take: First, you need to determine the extent of the damage. Assess how severe it is to decide if you can repair it or if you need to replace the entire pipe. Next, isolate and drain the section that is damaged. Shut off the water supply to that part of the pipe and drain any remaining water to prevent further leaks or damage. After that, clean the damaged area by removing any dirt, rust, or debris. You can use a wire brush or sandpaper for this job. Then, prepare the damaged area by roughening the surface with coarse sandpaper. This will help the repair material adhere better to the pipe. Next, choose a repair method based on the size and location of the damage. There are different options available such as using epoxy putty, pipe wraps, or clamps. Once you've chosen a repair method, follow the instructions provided to apply the repair material to the damaged area. Make sure it covers the entire damaged section and extends slightly beyond it for added protection. After applying the repair material, allow it to cure according to the manufacturer's instructions. This will ensure a strong bond and effective sealing of the damaged area. Once the repair has cured, turn the water supply back on and check for any leaks. If there are no signs of leakage, then the repair has been successful. If there are still leaks, you may need to reconsider the repair or seek professional help. Keep in mind that these steps are a general guideline for repairing damaged steel pipes. The specific repair method may vary depending on the size and severity of the damage. In more complex cases or if you're unsure, it's best to consult a professional plumber or pipe repair specialist.

- Q: What is the difference between steel pipes and PVC-O pipes?

- Steel pipes and PVC-O pipes differ in their material composition, strength, durability, and installation process. Steel pipes are made of steel, which makes them strong and suitable for high-pressure applications. However, they are prone to corrosion and require additional coating for protection. On the other hand, PVC-O pipes are made of a specially formulated, high-strength PVC material, which provides excellent resistance to corrosion, chemicals, and abrasion. PVC-O pipes are also lighter, easier to handle, and have a longer lifespan compared to steel pipes. Additionally, PVC-O pipes are installed using a jointing system, eliminating the need for welding or threading like steel pipes.

- Q: Can steel pipes be used for gas distribution?

- Yes, steel pipes can be used for gas distribution. Steel pipes are commonly used for transporting natural gas and other gases due to their high strength, durability, and resistance to corrosion. They can withstand high pressure and are suitable for long-distance gas distribution networks. However, it is important to ensure proper materials and installation techniques are used to prevent any potential safety hazards.

- Q: How are steel pipes resistant to corrosion?

- Steel pipes are resistant to corrosion due to the protective layer formed on their surface. This layer, also known as a passive film, is created through the presence of chromium in the steel. It acts as a barrier, preventing oxygen and moisture from reaching the underlying metal, thus inhibiting the corrosion process. Additionally, steel pipes can also be coated with anti-corrosive materials like zinc or epoxy, providing an extra layer of protection against rust and other corrosive elements.

- Q: What is the average lead time for manufacturing steel pipes?

- The average lead time for manufacturing steel pipes can vary depending on various factors such as size, complexity, and quantity. However, a typical range for lead time is generally around 4 to 8 weeks.

- Q: What are the different methods of pipe insulation for steel pipes?

- There are several methods of pipe insulation for steel pipes, including foam insulation, fiberglass insulation, mineral wool insulation, and reflective insulation. Foam insulation is a popular choice as it provides excellent thermal insulation and is easy to install. Fiberglass insulation is another common option that offers good thermal and acoustic insulation properties. Mineral wool insulation is known for its fire resistance and is often used in high-temperature applications. Reflective insulation, on the other hand, utilizes a reflective surface to reduce heat transfer and is commonly used in hot climates.

- Q: What are the different manufacturing standards for steel pipes?

- There are several manufacturing standards for steel pipes that are widely recognized and implemented in the industry. These standards ensure that the steel pipes are produced to meet specific requirements and quality standards. Some of the most common manufacturing standards for steel pipes include: 1. American Society for Testing and Materials (ASTM): ASTM standards are widely used in the United States and cover a wide range of steel pipe specifications. These standards include specifications for seamless and welded steel pipes, as well as various grades and dimensions. 2. International Organization for Standardization (ISO): ISO standards are globally recognized and provide guidelines for the production of steel pipes. ISO standards cover areas such as dimensions, materials, testing, and quality control. 3. European Norm (EN): EN standards are applicable in Europe and provide specifications for various types of steel pipes. These standards cover aspects such as dimensions, materials, manufacturing processes, and testing. 4. Japanese Industrial Standards (JIS): JIS standards are widely used in Japan and have gained international recognition. These standards cover dimensions, materials, and testing methods for steel pipes. 5. British Standards (BS): BS standards are commonly used in the United Kingdom and cover a range of steel pipe specifications. These standards include requirements for dimensions, materials, and testing procedures. 6. American Petroleum Institute (API): API standards are specifically developed for the oil and gas industry and cover various aspects of steel pipe manufacturing. These standards include specifications for seamless and welded pipes used in oil and gas exploration, production, and transportation. It is important for manufacturers, buyers, and users of steel pipes to be aware of these standards to ensure the quality, compatibility, and reliability of the pipes. Compliance with these standards helps to ensure that the steel pipes meet the necessary requirements and are suitable for their intended applications.

- Q: What is the role of steel pipes in the renewable energy sector?

- Steel pipes play a crucial role in the renewable energy sector by facilitating the transportation and distribution of various energy sources. One significant application of steel pipes is in the construction of pipelines for transporting natural gas, which is increasingly being used as a cleaner alternative to traditional fossil fuels. These pipelines are often made of steel due to its strength, durability, and resistance to corrosion, ensuring the safe and efficient delivery of natural gas to power plants and other energy consumers. Moreover, steel pipes are utilized in the installation of geothermal energy systems. Geothermal energy harnesses the heat from the earth's core to generate electricity or provide heating and cooling. Steel pipes are used to create geothermal wells, allowing for the extraction of hot water or steam from underground reservoirs. These pipes must withstand high temperatures and pressures, making steel an ideal material for this application. Additionally, steel pipes are employed in the construction of hydraulic systems for hydroelectric power plants. These plants rely on the force of flowing water to generate electricity, and steel pipes are used to convey water from the reservoir to the turbines. The durability and reliability of steel ensure the efficient transmission of water, enabling hydroelectric power plants to produce clean and renewable energy. In the renewable energy sector, steel pipes also play a role in the construction of solar power plants. Solar thermal systems use mirrors or lenses to concentrate sunlight and generate heat, which is then transferred to a fluid to produce steam and drive turbines. Steel pipes are essential for circulating and transferring this fluid, ensuring the effective operation of the solar power plant. In summary, steel pipes are indispensable in the renewable energy sector for their strength, durability, and resistance to corrosion. They enable the transportation of natural gas, the extraction of geothermal energy, the transmission of water in hydroelectric power plants, and the circulation of fluids in solar power plants. By facilitating the efficient distribution of various energy sources, steel pipes significantly contribute to the growth and sustainability of the renewable energy sector.

- Q: What are the different types of steel pipe supports for overhead piping?

- There are several types of steel pipe supports for overhead piping, including beam clamps, pipe hangers, clevis hangers, and riser clamps.

- Q: Where is a steel pipe casing usually used?

- A straight tube of carbon steel sheathed on pipes and tubes and threading tubes to protect the joints from damage by electric welding. The purpose is to protect the wires and cables.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2011;CE:2010 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Hui Ke Steel Pipe Co,.Ltd |

| Product Price Range | Average |

Send your message to us

ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords