ASTM 904l Stainless Steel Sheet factory direct sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

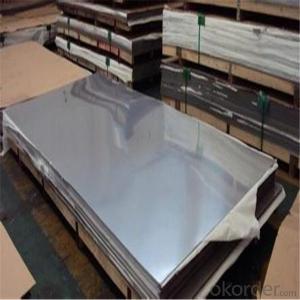

904l stainless steel sheet

| Commodity | 904L stainless steel sheet/plate | ||||||||

| Width | 1000mm/1219mm/1240mm/1500mm/2000mm or as customer’s requirements. | ||||||||

| Thickness | Cold rolled:0.3-3.0mm Hot rolled:3mm-150mm | ||||||||

| Length | 1000mm to 6000mm or as customer's request | ||||||||

| Surface | No.1,2b,8k,2d,Ba,No.4,No.6,No.8, etc. | ||||||||

| Material | 904L and we also have other grade,such as 201, 202, 301, 301, 302, 303, 304, 304L, 304N1, 309S, 310S, 316, 316L, 316Ti,316N, 317, 317L,321, 409L,410, 420, 430, etc. | ||||||||

| Grade | 900series | ||||||||

| Standards | AISI ASTM JIS SUS and GB | ||||||||

| Certifications | ISO 9001and SGS | ||||||||

| Applications | Kitchenware, utensils, tableware, household appliances, construction decoration and daily products | ||||||||

| Packing | Seaworthy wooden pallet or according to client's requirement | ||||||||

| Place of origin | Jiangsu China (mainland) | ||||||||

| Payment terms | T/T or L/C,30% by T/T in advance and the rest by T/T,L/C or as request. | ||||||||

| Delivery time | Up to order quantity | ||||||||

4.Hot rolled stainless steel plate

Thickness : 3.0mm-120mm

Width : 1219mm/1500mm/1800mm/2000mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 3.0mm-120mm(TK)*1219mm(W)*2438mm(L)

3.0mm-120mm(TK )*1500mm(W)*6000mm(L)

3.0mm-120mm(TK) *1800mm(W)*6000mm(L)

3.0mm-120mm(TK) *2000mm(W)*6000mm(L)

Surface : No.1

5.Characteristics and application

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

5.Payment : Usually 30% of the amount by T/T as deposit , and the balance money shall be paid by T/T after got the faxed B/L.Or L/C at sight .

6. Package: Kraft paper+Hard board+metal/wooden pallet+metal strip; or based on the customer requirement.

7. USE: construction.machinebuilding,container manufacturing,shipbuilding,bridges and so on.

The operating philosophy of our company : high quality and best service and competitive price and prompt delivery .We sincerely welcome the old and new customers to inquiry the price . any questions and needs you have , pls don't hesitate to contact us anytime .

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, making it an excellent choice for environments with high moisture and chemical exposure, such as wastewater treatment plants. It can withstand the harsh conditions and provide long-lasting durability. Additionally, stainless steel is easy to clean and maintain, which is essential in a wastewater treatment facility where cleanliness and hygiene are critical. The material also has a high strength-to-weight ratio, making it suitable for various applications within the plant, such as tanks, piping, and equipment. Overall, stainless steel sheets are a reliable and practical choice for wastewater treatment plants.

- Q: What are the different types of stainless steel sheet perforations available?

- There are several different types of stainless steel sheet perforations available, each with its own unique characteristics and applications. Some of the most common types include: 1. Round hole perforations: These are the most basic and widely used type of perforations. They are simple round holes evenly spaced across the sheet, providing good airflow and visibility. 2. Square hole perforations: Similar to round hole perforations, square holes offer a different aesthetic and can also be used for ventilation or decorative purposes. 3. Slotted perforations: Slotted holes are elongated and provide a larger open area compared to round or square holes. They are often used for drainage or filtering applications. 4. Hexagonal hole perforations: Hexagonal holes offer a unique pattern and are commonly used for architectural or decorative applications. They can also provide good airflow and visibility. 5. Decorative perforations: These types of perforations come in various shapes and designs, including floral, geometric, or abstract patterns. They are typically used for decorative purposes in applications such as building facades or interior design. 6. Micro-perforations: These are very small holes, typically less than 1mm in diameter. Micro-perforated sheets are used in applications where high precision and fine filtration are required, such as speaker grills or air diffusers. It's important to consider the specific requirements of your application when choosing the type of perforation. Factors such as open area, strength, visibility, and aesthetics should all be taken into account to ensure the best perforation choice for your specific needs.

- Q: Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment due to their excellent corrosion resistance, hygienic properties, and durability. Stainless steel is resistant to rust and corrosion caused by exposure to water, steam, and various chemicals commonly used in breweries. It can withstand high temperatures during brewing processes without degrading or affecting the taste of the final product. Additionally, stainless steel is easy to clean and maintain, ensuring the equipment remains sanitary and meets the strict hygiene standards required in the brewing industry.

- Q: What are the different sizes available for stainless steel sheets?

- Stainless steel sheets are available in various sizes, ranging from small sheets measuring a few inches in width and length, to larger sheets that can be several feet wide and long. The specific sizes available depend on the manufacturer and the intended use of the stainless steel sheets.

- Q: How do I remove stains or marks from stainless steel sheets?

- To remove stains or marks from stainless steel sheets, you can start by using a soft cloth or sponge with a mild soapy solution or dish detergent mixed with warm water. Gently scrub the affected area in the direction of the grain, rinsing with clean water afterward. For tougher stains, you can try using a non-abrasive cleaner specifically designed for stainless steel. Avoid using harsh chemicals or abrasive materials that can scratch the surface.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Can stainless steel sheets be used for brewery equipment?

- Indeed, brewery equipment can be constructed using stainless steel sheets. The reason behind stainless steel's popularity in brewery equipment lies in its ability to resist corrosion, its durability, and its hygienic properties. It can withstand the chemicals and acids typically employed in brewing processes without reacting with the beer, thus preserving the flavor and quality of the end product. Stainless steel sheets can be utilized to manufacture a variety of brewery equipment, including fermentation tanks, bright tanks, mash tuns, hot liquor tanks, and piping systems. Moreover, stainless steel is easy to clean and maintain, making it an ideal material for brewery equipment, where sanitation is of utmost importance.

- Q: Can stainless steel sheets be used for chemical reactors?

- Yes, stainless steel sheets can be used for chemical reactors. Stainless steel is a popular choice for chemical reactors due to its excellent corrosion resistance properties. It is highly resistant to chemical reactions with various substances, making it suitable for handling corrosive chemicals or environments. Stainless steel sheets are also known for their durability, high strength, and ability to withstand high temperatures, making them suitable for use in chemical reactors that may operate under extreme conditions. Additionally, stainless steel is easy to clean and maintain, which is crucial for ensuring the purity and integrity of the reaction process. Overall, stainless steel sheets are widely used in the construction of chemical reactors and are considered a reliable and effective material choice for this application.

- Q: Can stainless steel sheets be used for pharmaceutical storage cabinets?

- Yes, stainless steel sheets can be used for pharmaceutical storage cabinets. Stainless steel is highly resistant to corrosion, making it an ideal material for storing pharmaceuticals, which often require sterile and hygienic conditions. Stainless steel is also easy to clean and maintain, ensuring that the storage cabinets remain contamination-free. Additionally, stainless steel is durable and long-lasting, providing a reliable and secure storage solution for pharmaceuticals.

- Q: What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- You want to use argon arc welding. Stainless steel has good weldability, so you only need to weld it. Stainless steel welding is simple, the process is not high, plate deformation is very large, but after welding needs pickling and polishing.Argon arc welding is completely different from electrode welding. It has less welding defects because of its bright arc welding. No splash surface forming well.

Send your message to us

ASTM 904l Stainless Steel Sheet factory direct sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords