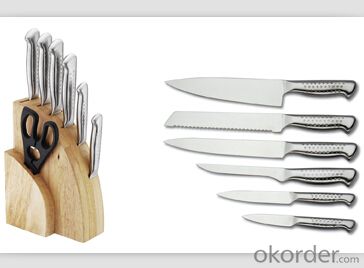

Art no. BLB1 Stainless steel knife set for kitchen

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Set includes:

1 × chef knife

1 × bread knife

1 × carving knife

1 × utility knife

1 × paring knife

High-carbon stainless steel blade holds a superior sharp edge

High quality stainless steel,tool vertical tough strong corrosion resistance

Comfortable grip handle for balance and control

Many other designs are available

Customized orders are accepted

Features:

Stainless steel knife blade with logo printed

Hard enough and sharp for cutting food

Easy to clean and save space

Fashion designnable design

Customized designs are welcome

OEM orders are welcome

Product advantages:

Wear resistant & extremely durable

Deathly sharp & stay sharp for years

Easy to clean to prevent bacteria growth

Blade high in density, chemically inert will not rust and do not react with acidic, food keep its original taste. No metal taste and smell

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Electronic Link

Experienced Staff Form A

Green Product Guarantee/Warranty

International Approvals Packaging

Price Product Features

Product Performance Quality Approvals

Reputation Service

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: What cutting properties should be provided for the cutting parts

- 1 high hardness tool material hardness is higher than the hardness of the workpiece material; wear resistance of 2 high wear resistance, is a comprehensive reflection of the tool material mechanical properties, microstructure and chemical properties; 3 sufficient strength and toughness; 4 high heat resistance; thermal physical properties of 5 and good thermal shock resistance 6; good technology and economic performance.

- Q: What are the commonly used tool materials

- High speed steel, cemented carbide, diamond, CBN., ceramic

- Q: Cutting tool materials

- Commonly used tool materials are divided into: tool steel (including carbon tool steel, alloy tool steel, high-speed steel), hard alloy, superhard cutting tool materials (including ceramics, diamond and cubic boron nitride, etc.)

- Q: What is the classification of the hardness level?

- Hard alloy tool hardness is generally between HRA89.5~92.8, the hardness of HSS is generally between HRC62~65, super hard high speed steel hardness is between HRC69~70, the hardness of carbon tool steel in general about HRC62, the hardness of diamond in the HV10000, the hardness of silicon carbide in HV4500, titanium carbide coating hardness HV3800, corundum hardness in the HV2400, tungsten carbide hard alloy hardness in 1300.

- Q: Want to buy a knife, you can select the steel carbon steel and high carbon steel, do not know the knife performance between big two kinds of steel making, see carbon steel knife can also be cut iron said selling knives on the site, do not know is not a bit exaggerated, but the price is a lot cheaper in carbon steel. Please master pointing

- Carbon steel finished steel, carbon containing higher hardness increases relatively more brittle, in the production of long knife, the hardness is not the only indicator, so we should consider various factors. The pattern is composed of steel with different carbon content of carbon steel (or different steel grades, but rare, is not easy to play) and co forging, but the shape of pattern steel on the market is far greater than the significance of practical significance, good-looking, but the performance is not necessarily improve.

- Q: How to maintain cutting tools?

- How to maintain the scene:1, to prevent contact between the blade tool placed collision caused by non cutting tool with xun.2, the tool to clear classification, avoid cutting tools and cutting materials caused by inconsistent tool with xun.3, to be familiar with the cutting performance and cutting tool materials. What materials are processed by a tool4, according to the cutting tool material and workpiece material selection reasonable tool geometry and cutting three elements.5, to be familiar with the machine tool and the relationship. For example: milling machine: what is the milling, what is the reverse milling, milling, reverse milling and cutting tool6, the tool should be consistent with the account.7, to meet the requirements of 5S management.

- Q: In machining, the relationship between the speed and the feed rate is very important

- Vc= PI nD/1000, Vc- line speed, n- speedVf=n*f Vf- feed speed n- f- feed per tooth

- Q: What are the factors that affect the tool life

- Cutting parameters.The cutting speed, feed rate and cutting depth have great influence on the tool life, and the cutting speed is the most important.

- Q: What do PCD cutters and PCBN cutters mean?

- PCD is diamond tool. Diamond cutter. PCBN is cubic boron nitride.

- Q: Woodworking engraving machine commonly used tools which?

- Taper ball end cutter, referred to as spherical cone. Is a mixture of spherical cone cone knife and knife, knife cone has the characteristics of it on the one hand, has a very small nose, on the other hand a knife features, can fine carving surface. The cone knife is often used to relief surface carving, engraving, carving and other relief image projection.Taper nose knife, knife cone taper is a mixture of bovine and bovine knife knife, knife cone has the characteristics of it on the one hand, has a small nose, fine carving and milling surface, on the other hand, has the characteristics of cownose knife, so the knife is often used in the nose taper relief surface engraving.Big head knife, in fact, the head of the cone angle larger cone knife. Mainly used for three-dimensional clearance.Drilling tool, mainly used for drilling. When the hole is relatively shallow, you can use a flat knife.

Send your message to us

Art no. BLB1 Stainless steel knife set for kitchen

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords