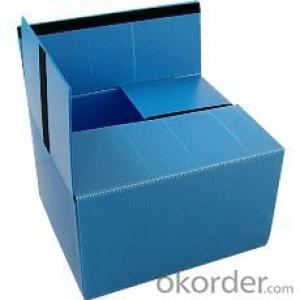

Anti-static PP Hollow Sheet with diffferent thickness and colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Anti-static PP Hollow Sheet with diffferent thickness and colors

Description | PP hollow sheet/PP corrugated sheet is a kind of environmental material, which is pollution-free and recyclable, made of polypropylene (PP) and polyethylene (PE) | |||||||||

Width | ≤2100mm | |||||||||

Length | As required. | |||||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 9mm | 10mm | 11mm | 12mm |

GSM | 250-500 | 300-600 | 600-900 | 800-1200 | 900-1600 | 1400-2000 | 1600-2000 | 1600-2200 | 2200-2400 | 2400-2600 |

Application | Packing | Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. | ||||||||

Advertising | Sign board,exhibition board,billboard,caution board,picture frame backing,digital printing and screen printing. | |||||||||

Decoration | Partitions,wall cladding,indoor and outdoor decoration,windows and false ceilings,floor cover,greenhouse roof. | |||||||||

Stationery and art design | It has multi-color,suitable for art design & various pattern box or delicate gift pack. | |||||||||

Feature | Light weight,rigid,strong and long time durable. | Waterproof,moisture resistance,excellent weather ability. | ||||||||

Chemical resistance,anti-impact,fade resistance. | Environmental friendly,recyclable,washable,non-toxic. | |||||||||

Easy to fabricate,custom-made cut shape. | Excellent surface for paints and inks easily,anti-corrosion. | |||||||||

Grade | Common,Corona Treated,Anti-Static,Conductive,UV Stabilized,etc. | |||||||||

Color | Clear,Black,White,Blue,Red,Yellow,Green,Pink,Or as required. | |||||||||

Advantage | Capacity:600MT per month; Prompt delivery; Factory Direct Selling; ISO-9001 | |||||||||

- Q: How can the packing box be mounted onto the board?

- It can be used for packing of many kinds of goods, suitable for long distance transportation packaging with bad transportation conditions. Plywood thickness is 6mm, 9mm, 12mm and other specifications.

- Q: Can the express company provide the computer's packing box?

- Some can, and some will not provide, specifically ask the courier company. It costs a lot of money to add a box... You'd better get the box to tell the truth, I suggest you host your own bag Kazakhstan is not too heavy that the flat display handled well, home for an LCD flat screen, or not good? Not expensive (second-hand) you ha go logistics account money, you have enough to buy a flat screen display.

- Q: Is it necessary to leave the packing cases for large household appliances?

- Best to stay for more than 7 days, because there is a problem is seven days replacement, replacement to the original box! Otherwise, do not change! Prescribed by the state! After the warranty is the manufacturer's problem! The manufacturer will engage in the houses!

- Q: What are the requirements for wooden packing boxes for exported goods?

- Any of various wooden materials, such as plywood or fiberboard, that are artificially processed or subjected to deep processing such as heating and pressurization. Except the plate rotary cutting core, sawdust, wood shavings, and the thickness is equal to or less than 6mm of wood materials.

- Q: How to prevent harmful substances in wooden packing box

- Generally speaking, these substances are divided into three kinds of fatigue: fungi, boring worms and marine boring animals. The most serious damage to wood is micro-organisms, which are mainly wood hiring bacteria and a small number of bacteria harm, so we are doing wood preservation, mainly to study the prevention of these fungi hazards. The growth of fungi must have four essential conditions: suitable temperature, adequate oxygen supply, adequate moisture, and nutrients suitable for the growth of fungi. If the four conditions are missing, they will prevent or prevent the erosion of fungi.

- Q: How about a carpenter's packing case?

- The vertical direction of the core plate (the difference between the core and the material) is poor, but the lateral flexural strength is higher. Both nail grip and water repellency are availableBetter than MDF and chipboard. The surface is generally rough and needs finishing (paint or decorative panels etc.). Simply speaking,A large piece of carpentry that must be nailed at home usually requires a large core board.But the large board itself uses a lot of glue, and a lot of glue or paint will be used in the finish, and the core boardPollutants are in open volatile state, so, home improvement must strictly control the use of large core board.

- Q: How can I remove the words from the wooden packing box?

- Only use the day to take water and other things, with a towel to get wet, and soak the place where the seal will be diluted. Because the materials of atomic and so forth are compounds, it is only the solvent of the compound that dissolves it.

- Q: Is the outer packing case and the turnover case a concept?

- The former is made of paper, and the latter is made of plastic. Of course, it is different

- Q: What are the L and R stands for steel cord packages?

- L is the left line (left), and the R is the right right. The left line refers to the line on the spool when face towards the left, when face down. The direction of the take-up is mainly related to the direction of the spindle's discharge in the tire factory, because the discharge system is in a direction, clockwise or counterclockwise. If the direction of the take-up is not correct, the spindle room worker will need to turn a single body to push the spool into the spool to increase the workload of the spindle room worker.

- Q: What are the general requirements for packing the goods by air?

- C. transportation conditions have limited goods, such as animal, perishable goods, dangerous goods, the packing should meet the requirements and provisions of this manual.

Send your message to us

Anti-static PP Hollow Sheet with diffferent thickness and colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords