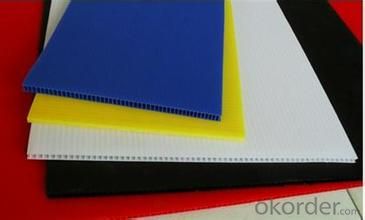

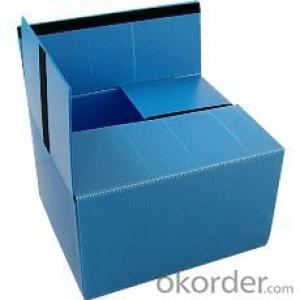

Extruded Polypropylene Package Sheet with different colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruded Polypropylene Package Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling,washable,durable and reuseable etc.CMAX PP corrugated sheet, Plastic HollowSheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

PP corrugated sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

- Q: What kind of wood is commonly used in wooden packing boxes?

- The main packing materials are light, light colored wood, such as pine and fir, and many are made of poplar plywood or medium and low density fiberboard.

- Q: What kind of material does the packing case have?

- Generally used as a mid-range packaging method, between the inner packing and the outer packing. Color package boxIt is usually made up of several colors, giving a strong visual sense, so that buyers and users can understand the details of the overall appearance and color of the goods. Especially suitable for the purchase of goods before we can take. It has been widely used in electronics, food, beverage, wine, tea, tobacco, medicine, health care products, cosmetics, small appliances, clothing, toys, sporting goods and other products packaging industry and supporting industries, is an indispensable industry.

- Q: Is it necessary to leave the packing cases for large household appliances?

- Just a week to go, and my family just bought a washing machine, and now the packing is gone.

- Q: Is the packing box for express delivered by ourselves or by courier company?

- Courier to the packagingAccording to kg and mileage, you say something so small not much money, give you a web site, there are many express phone, you can consult some express, can talk about the price, I cross provinces express a gauge to spend 12 yuan, courier packaging is done, good. The instrument is normal.

- Q: What's the square of the packing box?

- The packing box is a cube, so you have to work out the area of its 6 sides. Plus the overlap of the upper and lower openings of the packing carton and an overlap area around it. You can see the carton fully unfolded.

- Q: What are the requirements for wooden packing boxes for exported goods?

- Any of various wooden materials, such as plywood or fiberboard, that are artificially processed or subjected to deep processing such as heating and pressurization. Except the plate rotary cutting core, sawdust, wood shavings, and the thickness is equal to or less than 6mm of wood materials.

- Q: How do you calculate the weight of the packing box?

- It doesn't depend on your needs, because the materials used are different, the price is different, and the shape and structure of your goods are also considered. You like a cubic metre of wooden cases of a ton, if it is the entire piece of goods with foot can be fixed on the box and the bottom line as long as the strong side, can do some simple, it can save money, if it is required to do all parts of FCL stronger, but to increase the cost of.

- Q: What's the maximum size of the export packing box? What's the maximum size?

- 0262-93 described in this way: Carton support molding, the adjacent angle of 90 degrees, with an internal diameter of the tongue in the tongue, from the box mouth50mm don't take long and the amount of punishment box to box width, box bottom and top two in the distance between the roll cover box. But in the amount taken before a step must be made: one end of the swing cover together and support the carton forming, adjacent surface angle 90 degrees to gauge, the inner box with plate cover close to the box top outside shake cover open, the wooden ruler level

- Q: What's the name of the material used in paper packing boxes?

- According to the structure of the corrugated section, can be divided into A, B, C, D, E five corrugated cardboard. In accordance with the number of layers of corrugated can also be divided into one layer, double, three, five, seven layers of cardboard (ie three corrugated cardboard). Corrugated cardboard is the main feature of:(1) corrugated cardboard boxes made of corrugated cardboard are usually transported in the form of folding or tiling, which is easy to handle, improves transportation efficiency and saves storage space.(2) the cost of making corrugated cardboard packing boxes is low, and the materials are saved.(3) the utility model has the advantages of high strength and good buffering performance, and can avoid the collision and impact of the packaged goods, and is especially suitable for the transportation and packing of heavy products such as machinery, electromechanical, etc..(4) the production of corrugated boxes can be carried out on highly mechanized and automated equipment with high efficiency.

- Q: Does the air conditioner packing box contain the connecting copper pipe and the outer machine bracket?

- Some, anyway, tens of dollars to pay, installation fees on the right, do not pay to buy other materials

Send your message to us

Extruded Polypropylene Package Sheet with different colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords