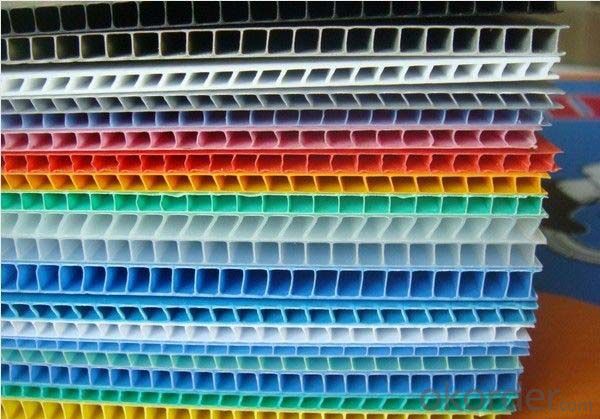

Extruded Polypropylene Hollow Sheet made of 100% virgin PP material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruded Polypropylene Hollow Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling,washable,durable and reuseable etc.CMAX PP corrugated sheet, Plastic HollowSheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

PP corrugated sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

- Q: How can the packing box be mounted onto the board?

- Usually, the flanging machine is refitted with a die, and the steel strip and the insert can be pressed onto the board. The steel side box, also called the steel box, the nail free box, or the fast packing case, is a popular packing box in recent years.

- Q: What kind of material does the packing case have?

- Material classification standardThey are divided into two broad categories: facial tissue and pit paper. Usually the box paper commonly used are: ash, copper, copper and copper nickel alloy single gorgeous card, gold card, platinum, silver, laser card etc.."White board" means that the single copper and copper nickel alloy. The common point is the single copper and copper on both sides is white. The difference is "copper": a smooth side is not smooth. Popular point is that the front can be printed, and the reverse can not be printed. "Single copper": both sides are coated with cloth, both positive and negative can be printed.The grey base board has this kind of paper, but it is not used on the packing box. It is called "gray copper paper". It is white and can be printed, and the reverse is gray. It can not be printed. General white is white board paper, but the general price of (except special white card, for example: white gold, silver card etc.). Packing box material: powder board paper, one side is white, one side is gray, the price is lower, double powder paper both sides are white, the price is on the high side

- Q: What enterprises need wooden packing box?

- We need wooden packing boxes for the production of various instruments, glass products, machinery factories and so on;The packing box is a national standard drafting unit of GB/T 7284-1998 frame wooden box, which is protected by national standard according to the characteristics of the goods transported or loaded. The box made of plates, and other components of the gear box.

- Q: Can the wooden packing box be transported by air directly? Or do you want to ship it in an air only container?

- Before the wood is packed, the wood needs to be fumigated before it can be transported by air. The same is true of shipping. The products packed in wood must be fumigated, and some countries are very sensitive to the transportation of wood. But the plywood doesn't need to be fumigated.

- Q: What's the packing box, gross weight?

- Gross weight is the total weight and net weight of the package after you pack your goods. The net weight is simply the weight of your goods. The gross weight is usually the weight of the goods + the weight of the filling + the weight of the outer packing

- Q: How do you calculate the weight of the packing box?

- According to your carton requirements, combined with GB6543-2008, 15kg bearing, carton size is 95cm less than 100cm (integrated carton length width and carton, choose corresponding board code BD1.1, code named D1.1 is good, but according to GB6544-2008, D1.1 side pressure is far not up to your requirements, need to choose D1.3 or D2.4 to to meet the requirements, the minimum amount of 560g corrugated board and 640g, one is the poor circulation environment, for good quality, then you can choose K250/M110*3/K200 (corrugated cardboard box board includes only the minimum comprehensive quantitative sandwich and paper, not including paper weight, the excellent products should be used in kraft paper), if the circulation environment is good good choose 250/M140*3/250 (said the glossy paper in the paper by 250g Hanging noodles or ordinary kraft paper, paper and paper core sandwich are made of 140g corrugated paper).

- Q: How do I distinguish between package types?

- Packaging container shape classification: can be divided into packaging boxes, packaging barrels, packaging bags, packaging bags, packaging baskets, packaging bundles, packaging jars, packaging cans, packaging tanks, bottles and so on.

- Q: What are the L and R stands for steel cord packages?

- The direction of the take-up is mainly related to the direction of the spindle's discharge in the tire factory, because the discharge system is in a direction, clockwise or counterclockwise.

- Q: What's the name of the material used in paper packing boxes?

- According to the structure of the corrugated section, can be divided into A, B, C, D, E five corrugated cardboard. In accordance with the number of layers of corrugated can also be divided into one layer, double, three, five, seven layers of cardboard (ie three corrugated cardboard). Corrugated cardboard is the main feature of:(1) corrugated cardboard boxes made of corrugated cardboard are usually transported in the form of folding or tiling, which is easy to handle, improves transportation efficiency and saves storage space.(2) the cost of making corrugated cardboard packing boxes is low, and the materials are saved.(3) the utility model has the advantages of high strength and good buffering performance, and can avoid the collision and impact of the packaged goods, and is especially suitable for the transportation and packing of heavy products such as machinery, electromechanical, etc..(4) the production of corrugated boxes can be carried out on highly mechanized and automated equipment with high efficiency.

- Q: What are the requirements and procedures for exporting wooden packing boxes?!

- The export packing box (export wooden packing box and export wooden case) has the advantages of good waterproof performance, simple production process, low cost, free fumigation and the like, and is also the best choice for replacing the ordinary wooden cases, and has strong adaptability. Complete compliance with export standards for packing cases.

Send your message to us

Extruded Polypropylene Hollow Sheet made of 100% virgin PP material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords