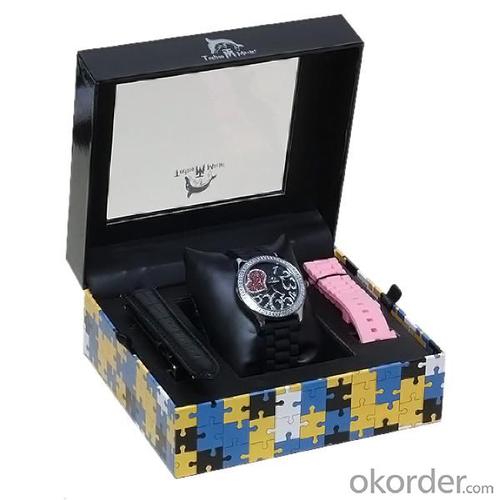

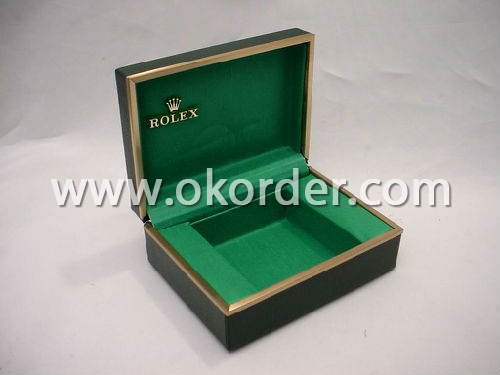

Specialized box

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100pcs pc

- Supply Capability:

- 50,000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications Of Specialized box :

1)Excellent self-standing for maximum display and presentation 2)Can be opened repeatedly if zipper is added, convenient to use, easy to store and good air tightness. 3)Highly versatile, suitable for multiple applications. 4)Good resistance to pressure and drop, non-breakage and non-leakage. 5)Low storage and transportation cost. 6)Easy tear with V-cut or laser scoring. 7)Wide range of punch hole can be incorporated. 2.Usage Of Specialized box : Laminated Zipper Bags are used for packing all kind of things like cometics, clothes, industry products etc. 3.Packaging & Delivery Of Specialized box : One 20GP container can be loaded about 10-15tons. By sea or by air all available. 4. Production Flow Of Specialized box : 1) the customer offers the artwork and we help design 2) confirmation for plates ordered 3) printing 4) laminating 5) separating and cutting 6) bag making 7) final inspection 8) shipping out Welcome to inquiry us anytime ,thank you and looking forward to service you soon !

- Q: What are the standards for carton boxes?

- Six angle drum turning testPut the carton into the six corners revolving drum with the impact plate, rotate according to the specified number of revolutions and times, and then check the damage of the goods and cartons.The above dynamic experiments are destructive and improve the resistance to damage of cartons and commodities by using cushion linings, partitions or other protective measures in the packaging of goods. In addition, some cartons need to be tested for spraying, weather resistance, etc., according to the contract agreement between the two parties.

- Q: Is it necessary to leave the packing cases for large household appliances?

- Need to, under normal circumstances, when you purchase, sales will tell how long to keep. However, according to my personal experience, in the 7 day return, 15 days replacement during the three package, you must keep. If the return, the attachment is not complete, as businesses and factories, to charge a certain amount of discount fee, a paper box, how much money you do not sell, but for businesses and factories, which belongs to the machine accessories, in the non professional customer service outlets, is impossible to buy. When you get out, but also to return, is very troublesome.

- Q: Can the wooden packing box be transported by air directly? Or do you want to ship it in an air only container?

- Before the wood is packed, the wood needs to be fumigated before it can be transported by air. The same is true of shipping. The products packed in wood must be fumigated, and some countries are very sensitive to the transportation of wood. But the plywood doesn't need to be fumigated.

- Q: What's the difference between wooden case packing and plywood packing?

- Wooden pallets to be sterilized, and now on the wooden pallets as long as the seal of IPCC can be, and do not have a certificate of disinfection.Plywood is the most convenient, and there is no need to consider the certificate of disinfection.

- Q: How to calculate the cost of producing the packing box?

- The production of corrugated cardboard cartons enterprises generally use varieties of costing, according to industry varieties open cost sheet.The direct materials need distribution, workshop production to issue requisitions, is the number into the number of the cost. Direct materials include a variety of paper and adhesives (corn flour or water glass), if they are flat nails and can be incorporated into supplementary material.

- Q: How can I remove the words from the wooden packing box?

- Only use the day to take water and other things, with a towel to get wet, and soak the place where the seal will be diluted. Because the materials of atomic and so forth are compounds, it is only the solvent of the compound that dissolves it.

- Q: What's the packing box, gross weight?

- That is, the weight after packing is not relative to the goods. The weight of the package is net weight

- Q: Where do you use wood containers?

- Can use wood packing box where we live from and be too numerous to enumerate, various related supplies and food to the processing plant products, machinery and equipment to, more far, expensive crafts packaging will also use wood packing box, wood box to loading watches, pen, large loading cars, large machinery and equipment that should be used in packaging box.In the final analysis, as long as the goods are to be transported, they need to be packed; to better protect the contents of the box, consider the use of load-bearing properties, compression, impact resistance of wood packaging box. Careful, you can also find that the bottom of the container is also wood.I hope my answer will help you. If you don't feel clear enough, you can add questions, and I will always pay attention to your problems.

- Q: What are the general requirements for packing the goods by air?

- A. packaging of goods should be strong and intact, can prevent the breakage of packing, loading, leakage loss during transportation; avoid stacking, friction, shock or pressure due to the temperature change and cause damage or deterioration of the goods; to prevent harm to the operator or pollution of aircraft, ground equipment and other items.

- Q: What are the requirements and procedures for exporting wooden packing boxes?!

- The export packing cases are made of wood as boxes and wooden boxes made of plywood. Plywood boxes are used in machinery, chemicals, electronics, hardware and other fields due to their flexibility in packing, adaptability to loading and reuse. Containing box plate and the fastening connector, and box board box adjacent box plate perpendicular to each other via the fastening connector, card stud connectors at the edge of each box plate are respectively fixed around the outer surface of a certain number of steel, the steel plate box adjacent card stud connectors respectively through angle at the adjacent board vertical junction connecting piece is provided with a long hole, and the end of the reverse bending fixed, the adjacent box plate is vertically fixed and connected, and a packing box.

1. Manufacturer Overview

| Location | Shenzhen,China |

| Year Established | 2011 |

| Annual Output Value | Above US$16 Million |

| Main Markets | Mid East;Western Europe;North America |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | English;Chinese;Japanese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Specialized box

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100pcs pc

- Supply Capability:

- 50,000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords