Package Box with Very Thick and Hard paper Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

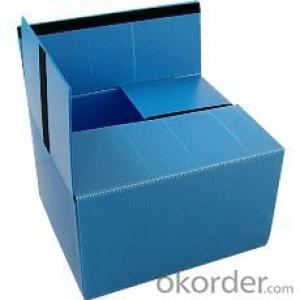

Introduction of Package Box

Package Box are made of hard paper coated with acrylic adhesive on both sides.

Application of Package Box

1. Industrial box parking

2. general purpose repair

3. gift wrapping &decoration

4. outside electronics product packing with safety material

5. bundling &strapping

6. stationery purpose

Advantage of Package Box

1.superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Package Box

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100pcs/carton(according to different specifications)

carton size : any carton size as your request

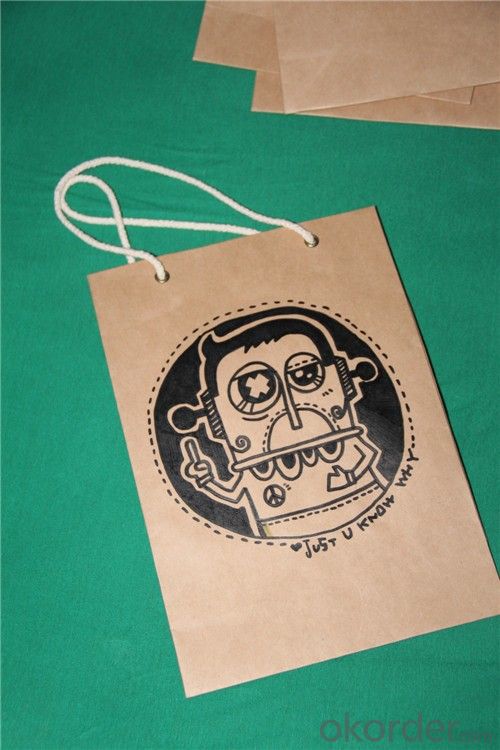

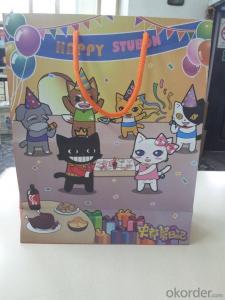

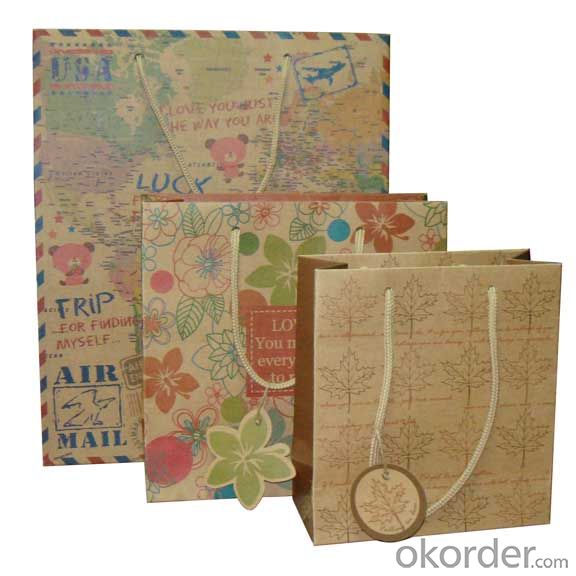

Pictures of Package Box

Specification of Package Box

| Material | PVC, PET, APET, PETG, PP,paper |

| Size/Shape | Customized |

| Thickness | 0.25mm-0.8mm |

| Variety of Products | Folding boxes, Tubes, Thermoformed, Die-cut products |

| Printing Options | UV offset printing, silkscreen printing, foil stamping, special effects printing |

| Full color comps of receipt of artwork time | Within a week |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks of Package Box:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your package box have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: What kind of material does the packing case have?

- Material classification standardThey are divided into two broad categories: facial tissue and pit paper. Usually the box paper commonly used are: ash, copper, copper and copper nickel alloy single gorgeous card, gold card, platinum, silver, laser card etc.."White board" means that the single copper and copper nickel alloy. The common point is the single copper and copper on both sides is white. The difference is "copper": a smooth side is not smooth. Popular point is that the front can be printed, and the reverse can not be printed. "Single copper": both sides are coated with cloth, both positive and negative can be printed.The grey base board has this kind of paper, but it is not used on the packing box. It is called "gray copper paper". It is white and can be printed, and the reverse is gray. It can not be printed. General white is white board paper, but the general price of (except special white card, for example: white gold, silver card etc.). Packing box material: powder board paper, one side is white, one side is gray, the price is lower, double powder paper both sides are white, the price is on the high side

- Q: Is it necessary to leave the packing cases for large household appliances?

- Need to, under normal circumstances, when you purchase, sales will tell how long to keep. However, according to my personal experience, in the 7 day return, 15 days replacement during the three package, you must keep. If the return, the attachment is not complete, as businesses and factories, to charge a certain amount of discount fee, a paper box, how much money you do not sell, but for businesses and factories, which belongs to the machine accessories, in the non professional customer service outlets, is impossible to buy. When you get out, but also to return, is very troublesome.

- Q: What enterprises need wooden packing box?

- Material classification1. Wooden packing box: packing container made of wood and bamboo.2. No fumigation packing box: packing container made of composite material.3, strong safety: plastic packaging container for patent engineering plastics made by special technology.4, corrugated packaging box: it is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q: What's the difference between wooden case packing and plywood packing?

- Plywood is a kind of synthetic packing material, which is generally used as an export package. Wooden boxes are usually made of logs and wooden boards. Most of the customs and quarantine departments in the country require that they be treated by fumigation. The wooden boxes after fumigation should be labeled with fumigation heat treatment. Fumigation is the use of chemicals in the logs of insects killed, heat treatment is high temperature, high humidity, killing insects. Heat treatment can also reduce the moisture content of wood, fumigation can not.

- Q: What are the requirements for wooden packing boxes for exported goods?

- Any of various wooden materials, such as plywood or fiberboard, that are artificially processed or subjected to deep processing such as heating and pressurization. Except the plate rotary cutting core, sawdust, wood shavings, and the thickness is equal to or less than 6mm of wood materials.

- Q: Is the outer packing case and the turnover case a concept?

- The former is made of paper, and the latter is made of plastic. Of course, it is different

- Q: How do I distinguish between package types?

- Packaging materials classification: can be divided into wooden products packaging, paper products packaging, metal products packaging, glass packaging, ceramic packaging and plastic products packaging.

- Q: What are the general requirements for packing the goods by air?

- Packing materials (such as sawdust, wastepaper) can not be leaked.

- Q: What are the requirements for product packaging?

- Non packaged products should be stored in rainproof, ventilated and dry places. And the product pad, in order to prevent moisture damage.The product must be inspected by the quality inspection department and accompanied by a product qualification certificate. The products must be inspected by the packing inspector before packing.Before packing, the dust and other dirt on the product must be removed. The whole packing process must be cleaned so as to ensure the quality of packing. Explosion proof electric products and power transmission control device should be covered with plastic bags and then put into the packing box. The outer packing is made of simple packing and should be packed in plastic bags first.

- Q: What are the requirements and procedures for exporting wooden packing boxes?!

- Export packing box, also known as: export wooden packing boxes, export wooden cases, plywood boxes, fumigation boxes, etc., refers to the export of goods in transit during the use of packaging containers.

Send your message to us

Package Box with Very Thick and Hard paper Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords