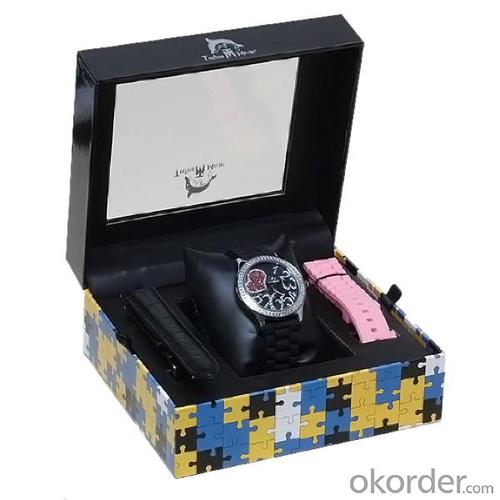

Watch Box

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100pcs m.t.

- Supply Capability:

- 500000pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications Of Watch Box :

1)Excellent self-standing for maximum display and presentation 2)Can be opened repeatedly if zipper is added, convenient to use, easy to store and good air tightness. 3)Highly versatile, suitable for multiple applications. 4)Good resistance to pressure and drop, non-breakage and non-leakage. 5)Low storage and transportation cost. 6)Easy tear with V-cut or laser scoring. 7)Wide range of punch hole can be incorporated. 2.Usage Of Watch Box : Laminated Zipper Bags are used for packing all kind of things like cometics, clothes, industry products etc. 3.Packaging & Delivery Of Watch Box : One 20GP container can be loaded about 10-15tons. By sea or by air all available. 4. Production Flow Of Watch Box : 1) the customer offers the artwork and we help design 2) confirmation for plates ordered 3) printing 4) laminating 5) separating and cutting 6) bag making 7) final inspection 8) shipping out Welcome to inquiry us anytime ,thank you and looking forward to service you soon !

- Q: What enterprises need wooden packing box?

- Material classification1. Wooden packing box: packing container made of wood and bamboo.2. No fumigation packing box: packing container made of composite material.3, strong safety: plastic packaging container for patent engineering plastics made by special technology.4, corrugated packaging box: it is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q: What are the requirements for wooden packing boxes for exported goods?

- Any of various wooden materials, such as plywood or fiberboard, that are artificially processed or subjected to deep processing such as heating and pressurization. Except the plate rotary cutting core, sawdust, wood shavings, and the thickness is equal to or less than 6mm of wood materials.

- Q: How about a carpenter's packing case?

- The vertical direction of the core plate (the difference between the core and the material) is poor, but the lateral flexural strength is higher. Both nail grip and water repellency are availableBetter than MDF and chipboard. The surface is generally rough and needs finishing (paint or decorative panels etc.). Simply speaking,A large piece of carpentry that must be nailed at home usually requires a large core board.But the large board itself uses a lot of glue, and a lot of glue or paint will be used in the finish, and the core boardPollutants are in open volatile state, so, home improvement must strictly control the use of large core board.

- Q: How to calculate the cost of producing the packing box?

- Direct labor is the production workers the wages of workers, according to the actual amount of time each number is allocated if the time statistic is not accurate, can according to the actual price of the price is the variety of merchandise value as the standard for distribution, distribution of the selected standard, since the code in an accounting period do not change;

- Q: Is the outer packing case and the turnover case a concept?

- In some cases, the two refers to a traditional logistics and some of the goods are often carried out directly with the outer packing box turnover, with the construction of modern logistics system, this situation is less and less

- Q: What are the L and R stands for steel cord packages?

- If the direction of the take-up is not correct, the spindle room worker will need to turn a single body to push the spool into the spool to increase the workload of the spindle room worker.

- Q: What's the name of the material used in paper packing boxes?

- Corrugated cardboard featuresCorrugated board is a widely used paper instead of wood, especially for commodity packaging. According to the shape of corrugated can be divided into u, V, UV corrugated.

- Q: What are the general requirements for packing the goods by air?

- C. transportation conditions have limited goods, such as animal, perishable goods, dangerous goods, the packing should meet the requirements and provisions of this manual.

- Q: What are the requirements for export packing?

- To facilitate the operation of all aspects of the relevant personnel. This requires reasonable packaging design, packaging specifications, weight, size, packaging technology, packaging clearly marked in order to adapt to the standardization of transport packaging requirements.

- Q: What are the requirements for product packaging?

- Non packaged products should be stored in rainproof, ventilated and dry places. And the product pad, in order to prevent moisture damage.The product must be inspected by the quality inspection department and accompanied by a product qualification certificate. The products must be inspected by the packing inspector before packing.Before packing, the dust and other dirt on the product must be removed. The whole packing process must be cleaned so as to ensure the quality of packing. Explosion proof electric products and power transmission control device should be covered with plastic bags and then put into the packing box. The outer packing is made of simple packing and should be packed in plastic bags first.

1. Manufacturer Overview

| Location | Shenzhen,China |

| Year Established | 2011 |

| Annual Output Value | Above US$16 Million |

| Main Markets | Mid East;Western Europe;North America |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | English;Chinese;Japanese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Watch Box

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100pcs m.t.

- Supply Capability:

- 500000pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords