Package Box Hard for Different Products with Different Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Package Box

Package Box are made of hard paper coated with acrylic adhesive on both sides.

Application of Package Box

1. Industrial box parking

2. general purpose repair

3. gift wrapping &decoration

4. outside electronics product packing with safety material

5. bundling &strapping

6. stationery purpose

Advantage of Package Box

1.superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Package Box

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100pcs/carton(according to different specifications)

carton size : any carton size as your request

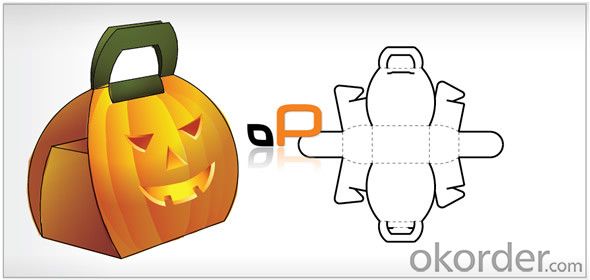

Pictures of Package Box

Specification of Package Box

| Material | PVC, PET, APET, PETG, PP,paper |

| Size/Shape | Customized |

| Thickness | 0.25mm-0.8mm |

| Variety of Products | Folding boxes, Tubes, Thermoformed, Die-cut products |

| Printing Options | UV offset printing, silkscreen printing, foil stamping, special effects printing |

| Full color comps of receipt of artwork time | Within a week |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks of Package Box:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your package box have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: What enterprises need wooden packing box?

- We need wooden packing boxes for the production of various instruments, glass products, machinery factories and so on;The packing box is a national standard drafting unit of GB/T 7284-1998 frame wooden box, which is protected by national standard according to the characteristics of the goods transported or loaded. The box made of plates, and other components of the gear box.

- Q: What's the square of the packing box?

- The packing box is a national standard drafting unit of GB/T 7284-1998 frame wooden box, which is protected by national standard according to the characteristics of the goods transported or loaded. The box made of plates, and other components of the gear box.

- Q: What are the requirements for wooden packing boxes for exported goods?

- Any of various wooden materials, such as plywood or fiberboard, that are artificially processed or subjected to deep processing such as heating and pressurization. Except the plate rotary cutting core, sawdust, wood shavings, and the thickness is equal to or less than 6mm of wood materials.

- Q: How to prevent harmful substances in wooden packing box

- Wood preservation, quarantine and disposal are based on this principle. The use of dry kiln heat treatment of wood, from the temperature, moisture content damage fungal survival conditions, is an ideal and useful disposal methods. About the most natural fungi, when the wood moisture content below 20% or reaching saturation, the growth is limited; in 12 DEG, 46 DEG C, almost completely stopped the growth of fungi. As a result, we can heat the wood in a dry kiln and reduce the final moisture content to less than 20%, so as to achieve the purpose of insect killing and sterilization.

- Q: How can I remove the words from the wooden packing box?

- Rub it slowly with a corner grinder and wipe it out

- Q: Where do you use wood containers?

- First of all, the packing box is to protect the objects in the box for the ultimate purpose.

- Q: What's the maximum size of the export packing box? What's the maximum size?

- It depends on the product and the packing method.Generally speaking, if it is a general small product, it is suggested that the cartons should not be too large and too heavy to be packed. It is best to be suitable for a person to carry (for example, within 20 kg of gross weight, not more than 40*30*30 in size).

- Q: What are the L and R stands for steel cord packages?

- L is the left line (left), and the R is the right right. The left line refers to the line on the spool when face towards the left, when face down. The direction of the take-up is mainly related to the direction of the spindle's discharge in the tire factory, because the discharge system is in a direction, clockwise or counterclockwise. If the direction of the take-up is not correct, the spindle room worker will need to turn a single body to push the spool into the spool to increase the workload of the spindle room worker.

- Q: What are the requirements for export packing?

- To moderate packaging, in ensuring the premise of solid packaging to save packaging costs. The transportation cost is often directly related to the weight and volume of transportation package. Packaging costs directly affect the economic efficiency of enterprises, therefore, the choice of packaging materials should be light, strong, moderate.

- Q: What are the requirements and procedures for exporting wooden packing boxes?!

- The export packing box (export wooden packing box and export wooden case) has the advantages of good waterproof performance, simple production process, low cost, free fumigation and the like, and is also the best choice for replacing the ordinary wooden cases, and has strong adaptability. Complete compliance with export standards for packing cases.

Send your message to us

Package Box Hard for Different Products with Different Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords