Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

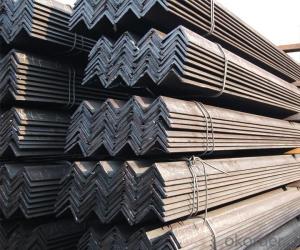

OKorder is offering high quality Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel angles be used in the construction of agricultural buildings?

- Yes, steel angles can be used in the construction of agricultural buildings. Steel angles are commonly used as structural components for framing, bracing, and supporting various elements in agricultural buildings such as walls, roofs, and machinery. They provide strength, stability, and durability, making them suitable for withstanding the load and environmental conditions typically encountered in agricultural settings.

- Q: Can steel angles be used in storage rack systems?

- Yes, steel angles can be used in storage rack systems. Steel angles are commonly used in the construction industry and have a variety of applications, including storage racks. They provide structural support and stability to the rack system, making them suitable for storing heavy items. Steel angles are strong, durable, and resistant to bending or warping under heavy loads, making them ideal for supporting shelves and organizing materials in storage racks. Additionally, steel angles can be easily welded or bolted together, allowing for easy customization and flexibility in designing storage rack systems. Overall, steel angles are a reliable and cost-effective option for building storage rack systems.

- Q: How do you protect steel angles from moisture?

- Steel angles can be protected from moisture by applying a suitable coating or paint that acts as a barrier against moisture. Additionally, regular inspection and maintenance, including the removal of any rust or corrosion, can help prevent moisture damage.

- Q: How to determine the neutral axis of the angle bar?

- The neutral axis of angle iron or channel steel needs to be calculated, but it can be checked directly.

- Q: Can steel angles be used for pipe support systems?

- Yes, steel angles can be used for pipe support systems. Steel angles are commonly used in construction and engineering projects for their strength, stability, and versatility. When used as pipe supports, steel angles provide a sturdy and reliable structure to hold and secure pipes in place. They can be easily welded or bolted to other structural components, making them suitable for various pipe support applications. Additionally, steel angles can be fabricated and customized to meet specific requirements, such as different pipe sizes and load-bearing capacities. Overall, steel angles are a popular choice for pipe support systems due to their durability and ability to withstand heavy loads.

- Q: How do you calculate the axial load capacity of a steel angle?

- To calculate the axial load capacity of a steel angle, you need to consider several factors including the material properties of the angle, its dimensions, the type of loading, and the safety factor. First, you should determine the yield strength of the steel angle. This value represents the maximum stress the angle can withstand without permanent deformation. The yield strength can be obtained from the steel angle's specifications or by conducting material testing. Next, you need to measure the dimensions of the angle, including its length, thickness, and width. These values are crucial in determining the area of the cross-section of the angle. Once you have the yield strength and the cross-sectional area, you can calculate the axial load capacity using the formula: Axial load capacity = Yield strength × Cross-sectional area It is important to note that this formula assumes that the angle is subjected to direct axial loading. If the angle is subjected to combined loading or other complex loading conditions, additional calculations or structural analysis may be required. Moreover, it is customary to apply a safety factor to the calculated axial load capacity to account for uncertainties and ensure structural integrity. The safety factor is typically determined based on the specific application and industry standards. For example, a safety factor of 1.5 is commonly used in structural design. In summary, to calculate the axial load capacity of a steel angle, you need to know its yield strength, measure its dimensions, and apply the appropriate safety factor. This calculation provides an estimate of the maximum load the angle can bear without failure under axial loading conditions.

- Q: How do you store and transport steel angles?

- In order to ensure the safety and prevent damage of steel angles during storage and transportation, it is crucial to adhere to specific guidelines. Consider the following steps: 1. Find an appropriate storage location: Locate a well-ventilated, dry, and clean area that is free from moisture or chemicals that may cause corrosion. Ideally, choose an indoor storage area to shield the steel angles from the elements. 2. Properly organize and stack: Prioritize organizing the steel angles according to their size, shape, and weight. Stack them horizontally, one on top of another, with heavier angles at the bottom to prevent deformation or damage to lighter ones. Insert wooden or rubber spacers between layers to minimize direct contact and reduce the risk of scratches or other surface flaws. 3. Secure the stack: Use strong metal bands, straps, or chains to tightly bind the stack of steel angles. This will prevent movement during transportation and decrease the chances of accidents or damage. 4. Utilize appropriate lifting equipment: When handling steel angles, it is crucial to employ suitable lifting equipment such as cranes, forklifts, or hoists. Ensure that the equipment has the necessary capacity to safely lift the angles and distribute the lifting points evenly to avoid bending or distortion. 5. Guard against corrosion: Prior to storage and transportation, apply a corrosion-resistant coating or protective oil film to the steel angles. This will help prevent rusting and other forms of corrosion caused by exposure to moisture or environmental factors. 6. Secure packaging during transportation: If the steel angles need to be transported over long distances, consider using appropriate packaging materials like wooden crates or steel pallets to provide additional protection. Fasten the angles securely to the packaging to prevent any movement or shifting during transit. 7. Regularly inspect: Conduct regular inspections of the stored and transported steel angles to identify any signs of corrosion, damage, or deformation. Take immediate action to prevent further deterioration if any issues are detected. By adhering to these guidelines, you can ensure the safe storage and transportation of steel angles, thereby minimizing the risk of damage and preserving their quality.

- Q: What are the common methods of surface preparation for steel angles?

- The common methods of surface preparation for steel angles include grinding, sandblasting, and chemical cleaning. Grinding is a mechanical method where the surface of the steel angle is smoothed and leveled using an abrasive wheel or disc. This method is effective in removing rust, scale, and other surface imperfections. It is commonly used for small-scale projects or when a smooth surface finish is not critical. Sandblasting, also known as abrasive blasting, involves propelling small particles at high speeds onto the surface of the steel angle. This method is highly effective in removing mill scale, rust, paint, and other contaminants. Sandblasting provides a roughened surface that promotes better adhesion of coatings or paints. It is commonly used in large-scale industrial projects where a high-quality surface finish is required. Chemical cleaning involves using chemical solutions to remove contaminants from the surface of the steel angle. This method is effective in removing rust, oil, grease, and other organic materials. Chemical cleaning can be done through various techniques such as immersion or brush application. It is commonly used when sandblasting or grinding may not be feasible or practical. In addition to these methods, other surface preparation techniques may include power tool cleaning, flame cleaning, or a combination of methods depending on the specific requirements of the project. It is important to choose the appropriate method based on the condition of the steel angle, the desired surface finish, and the intended application of the steel angle.

- Q: What are the different methods of reinforcing steel angles?

- There are several methods of reinforcing steel angles, each with its own advantages and applications. One common method is the use of additional steel plates or brackets. These plates or brackets are typically welded or bolted to the existing steel angle to provide additional support and strength. This method is often used in applications where the steel angle is subject to high loads or stresses. Another method is the use of stiffeners, which are typically smaller steel angles or plates welded perpendicular to the existing angle. These stiffeners help to distribute the load more evenly and prevent the steel angle from buckling or bending under stress. This method is often used in applications where the steel angle is used as a structural member, such as in building frames or bridge supports. Additionally, reinforcing steel angles can be achieved through the use of concrete encasement or composite materials. In this method, the steel angle is embedded within a concrete matrix or combined with other materials such as fiberglass or carbon fiber. This combination provides enhanced strength, durability, and resistance to corrosion. This method is commonly used in construction projects where the steel angle is exposed to harsh environments or requires high performance. Overall, the different methods of reinforcing steel angles provide options for increasing the strength, stability, and durability of these structural components. The choice of method will depend on the specific application, load requirements, and environmental factors.

- Q: What are the common welding techniques used for steel angles?

- The common welding techniques used for steel angles include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding (Shielded Metal Arc Welding - SMAW). MIG welding, also known as GMAW (Gas Metal Arc Welding), is a widely used technique that involves feeding a continuous wire electrode into the weld pool while an inert gas, such as argon or a mixture of argon and carbon dioxide, is used to shield the weld zone from atmospheric contamination. MIG welding is known for its ease of use, high welding speeds, and ability to handle thicker materials. TIG welding, also known as GTAW (Gas Tungsten Arc Welding), is a more precise welding technique that uses a non-consumable tungsten electrode to create the arc and a separate filler material if necessary. TIG welding provides excellent control over the weld pool and produces high-quality welds with minimal spatter. It is commonly used for thinner materials and applications that require a higher level of precision. Stick welding, also known as SMAW (Shielded Metal Arc Welding), is a versatile and widely used welding process. It involves striking an arc between a flux-coated electrode and the workpiece, creating a weld pool that is protected by the flux coating. Stick welding is known for its portability and ability to handle various materials and thicknesses. It is commonly used in construction, maintenance, and repair work. These welding techniques can be used for steel angles, which are often found in structural applications, such as frames, braces, and supports. The selection of the welding technique depends on factors such as the thickness of the steel angle, the required weld quality, and the specific application. It is important to consider the welding process, proper joint preparation, and welding parameters to ensure a strong and durable weld joint.

Send your message to us

Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords