Aluminum Zinc Rolled Coil for Steel Roof Build

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

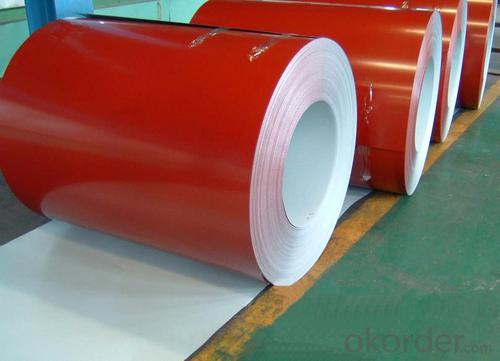

Aluminum Zinc Rolled Coil for Steel Roof Building

Aluminum Zinc Rolled Coil for Steel Roof Building

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Aluminum Zinc Rolled Coil for Steel Roof Building

1) Aluminum zinc coils is formable, weldable and paintable.

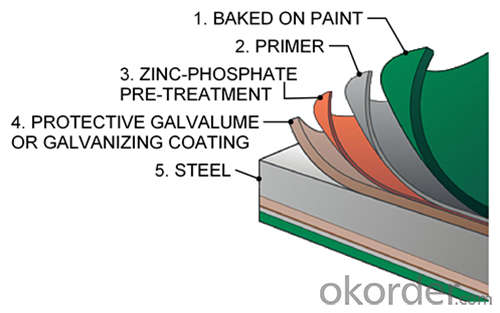

2) Aluminum zinc coils has superior long term corrosion resistance in the most atmospheric conditions. This is achieved through the combination of the sacrificial protection of the zinc and the barrier protection of the aluminum.

3) Aluminum zinc coils coating out-perform galvanized coating from 2-6 times than hot dip galvanized steel.

Aluminum Zinc Rolled Coil for Steel Roof Building

1) Construction: Roofing, cladding, structural sections, composite panels, etc.

2) Electric appliance: Washing machine, refrigerators, toaster, microwave, etc.

3) Miscellaneous: Air duct, lighting, computer casing, etc.

Aluminum Zinc Rolled Coil for Steel Roof Building

Aluminum Zinc Rolled Coil for Steel Roof Building

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- steel is a mixture of two or more metal or a metal with non metal to obtain both properties of the indivudual components. carbon steel for example.

- Q: How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery as they serve as the raw material for manufacturing various components of the machinery, such as frames, supports, and structural elements. The steel coils are processed through cutting, bending, and welding to create the necessary parts, ensuring durability and stability in the packaging machinery's construction.

- Q: How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through various methods such as applying protective coatings, using edge protectors, securely packaging them with appropriate materials, and ensuring careful handling during transportation and storage.

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks by being shaped and cut into the desired hook shape. The coils are uncoiled and fed into a machine where they undergo various processes such as bending, shaping, and welding to form the hooks. The strength and durability of the steel coils contribute to the quality and reliability of the final steel hooks.

- Q: How are steel coils used in the production of roofing and siding?

- Roofing and siding materials heavily rely on steel coils as a vital element. These coils, crafted from high-quality steel, undergo several processes to convert them into the final products used in roofing and siding. To start with, the steel coils are unwound and flattened to obtain a smooth steel sheet. Subsequently, this sheet is thoroughly cleansed to eliminate any impurities or contaminants. The cleansing procedure involves treating the steel's surface with chemicals and rinsing it meticulously to ensure a spotless and sleek surface. Following this, the steel sheet receives a protective layer to enhance its durability and resistance against corrosion. This coating can be executed through various techniques such as hot-dip galvanizing, electro-galvanizing, or applying a metallic or organic layer. The preferred method of coating depends on the desired properties and aesthetic requirements of the roofing or siding material. After the coating process, the steel sheet is shaped and formed into the desired structure and profile. For roofing purposes, the steel sheet is commonly corrugated or shaped into interlocking panels. This facilitates easy installation and guarantees a secure and weather-resistant roofing system. Similarly, for siding applications, the steel sheet can adopt various profiles like horizontal or vertical panels, shingles, or shakes. Once the steel sheet is formed, it may undergo additional treatments to improve its performance. This can involve applying a protective coat of paint or other finishes to enhance its appearance and resistance against fading, chipping, or scratching. The steel coils can also be embossed or stamped with patterns or textures to provide aesthetic appeal. In conclusion, steel coils play a vital role in the production of roofing and siding materials. They offer strength, durability, and weather resistance, making them an ideal choice for safeguarding structures from the elements. Furthermore, steel coils provide versatility in terms of shape, profile, and finish, allowing for a wide range of design options for roofing and siding applications.

- Q: Are steel or graphite clubs better?

- I use steel shaft golf clubs (mens so called clubs) I find the garphite shaft that is typically used for womens clubs is too light and I have a messy swing Callaway Big Bertha is GREAT .... very forgiving club and the oversized clubhead is great for beginners up to advanced. *****FOR MEN - STEEL******* no graphite (just the woods have graphite shafts but the irons are steel

- Q: What are the different grades of steel coils?

- There are various grades of steel coils available, including but not limited to, low carbon steel, high carbon steel, stainless steel, and alloy steel. These different grades offer varying levels of strength, corrosion resistance, and other mechanical properties, allowing them to be used for various applications in industries such as automotive, construction, and manufacturing.

- Q: How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems as they are shaped and formed into various components such as brake discs, brake pads, and brake calipers. These coils are made of high-quality steel that provides strength and durability, ensuring efficient and reliable braking performance for vehicles.

- Q: What is the maximum temperature steel coils can withstand?

- The specific grade and type of steel being used determine the maximum temperature that steel coils can tolerate. Steel possesses strong heat resistance and can generally endure temperatures ranging from 550°C to 1,100°C (1,022°F to 2,012°F), depending on the grade. Nevertheless, it is essential to acknowledge that extended exposure to high temperatures may compromise the structural integrity of the steel, leading to permanent deformation or failure. Hence, it is crucial to adhere to the manufacturer's guidelines and specifications when establishing the maximum temperature that steel coils can withstand for particular applications.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- Reinforced Steel is found in concrete, and if the towers were built with reinforced concrete (concrete beams with rebar) then they would likely still be standing. The twin towers were made of steel. When steel is heated up, it deforms and collapses, which is why it didnt stand up. One of the top 2 things against steel is that it is not fire resistant.

Send your message to us

Aluminum Zinc Rolled Coil for Steel Roof Build

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords