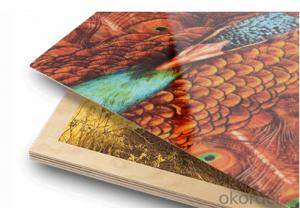

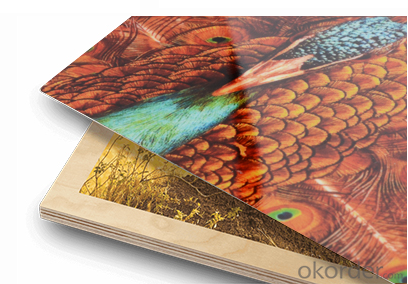

Aluminum Sheets Maine - 2016 Manufacturer Four Colors and Spot Color HD Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on factors such as alloy composition, tempering, and thickness. However, generally, aluminum sheets have a moderate impact strength, making them suitable for many applications that require resistance to impact and denting.

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets varies depending on the specific alloy used. However, on average, aluminum has a coefficient of thermal expansion of approximately 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). This means that for every degree increase in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It is important to note that this value may slightly differ for different grades and alloys of aluminum.

- Q: What is the dielectric strength of aluminum sheets?

- The dielectric strength of aluminum sheets is typically around 20-30 kilovolts per millimeter (kV/mm).

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: Can aluminum sheets be used for honeycomb panels?

- Yes, aluminum sheets can be used for honeycomb panels. The lightweight yet sturdy nature of aluminum makes it a popular choice for constructing honeycomb panels, which are commonly used in aerospace, automotive, and construction industries for their strength-to-weight ratio and structural integrity.

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess several physical properties, including being lightweight, corrosion-resistant, and having a high strength-to-weight ratio. They are also ductile, meaning they can be easily shaped or formed without breaking. Additionally, aluminum sheets have excellent thermal and electrical conductivity, making them suitable for various applications in industries such as construction, aerospace, and automotive.

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed. Aluminum is a highly malleable and ductile metal, which means it can easily be shaped or bent without breaking. This characteristic makes it a popular choice for various applications, such as manufacturing automotive parts, aircraft structures, and household items. Aluminum sheets can be bent or formed using various techniques, such as press braking, roll bending, and stretch forming. These methods allow the aluminum sheets to be shaped into different angles or curves to meet specific design requirements.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a popular choice for food display cases due to its exceptional strength, durability, and resistance to corrosion. Additionally, aluminum is lightweight, making it easier to handle and transport the display cases. Its clean, sleek appearance also enhances the presentation of the food items, making it an ideal material for showcasing various food products. Moreover, aluminum is non-toxic and does not react with food, ensuring the safety and hygiene of the displayed items. Overall, aluminum sheets are a suitable and practical choice for constructing food display cases.

- Q: What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. Aluminum is a versatile and lightweight material that possesses several beneficial properties for construction purposes. It is corrosion-resistant, making it suitable for both indoor and outdoor applications. Aluminum sheets also have high strength-to-weight ratio, meaning they offer strength and durability while remaining relatively lightweight, which can be advantageous in construction projects where weight is a concern. Additionally, aluminum is non-toxic and highly recyclable, making it an environmentally friendly choice. These factors, combined with its aesthetic appeal and ease of fabrication, make aluminum sheets a popular choice for various construction applications such as roofing, cladding, wall panels, window frames, and more.

Send your message to us

Aluminum Sheets Maine - 2016 Manufacturer Four Colors and Spot Color HD Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords