Aluminum Sheets for Sale - Aluminium Profile Building Expansion Joints

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile Building Expansion Joints Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Building Expansion Joints:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

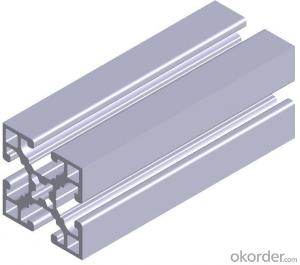

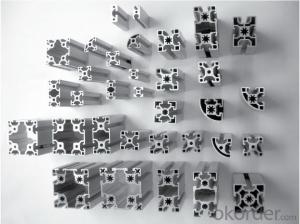

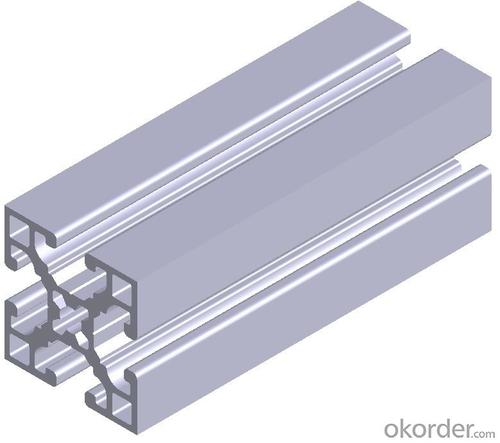

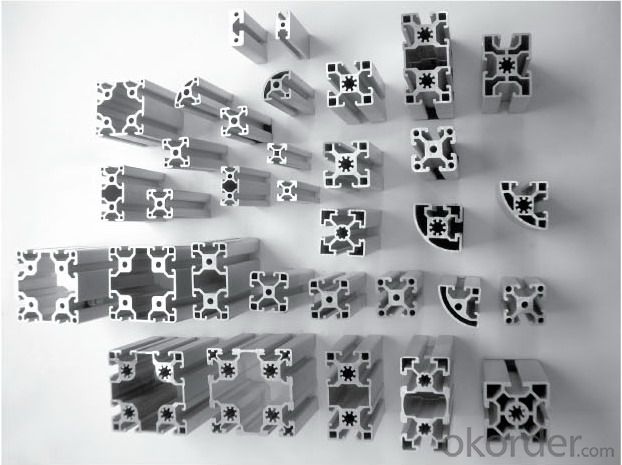

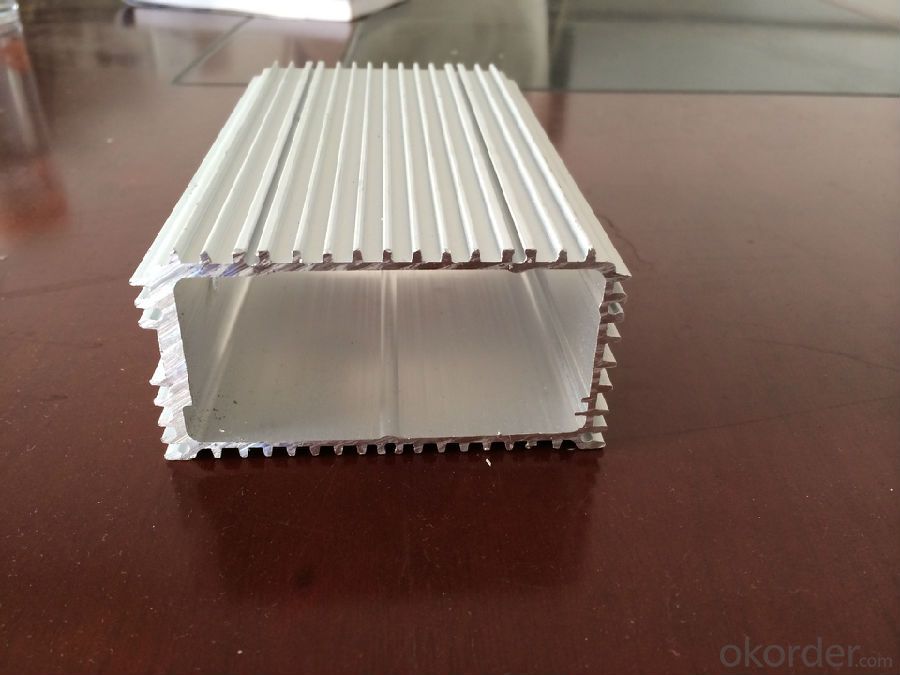

3.Aluminium Profile Building Expansion Joints Images:

4.Aluminium Profile Building Expansion JointsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used for electrical connectors?

- Yes, aluminum sheets can be used for electrical connectors.

- Q: What is the modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets, also known as Young's modulus, is typically around 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This value represents the measure of the stiffness or rigidity of the material. However, it is important to note that the modulus of elasticity can vary slightly depending on the specific alloy composition and tempering of the aluminum sheet.

- Q: What are the applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties and versatility. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are used in the construction industry for various purposes such as roofing, siding, gutters, and facades. They offer excellent durability, corrosion resistance, and the ability to withstand extreme weather conditions. 2. Transportation: Aluminum sheets are extensively used in the transportation industry, particularly in the manufacturing of automobiles, airplanes, trains, and ships. Their lightweight nature helps reduce fuel consumption and enhance vehicle performance while maintaining strength and durability. 3. Packaging: Aluminum sheets are widely used for packaging purposes, especially in the food and beverage industry. They are used for making cans, foils, and containers due to their ability to protect the contents from light, moisture, air, and bacteria. 4. Electronics: Aluminum sheets are used in the production of electronic devices, such as laptops, smartphones, and tablets. They are often used for heat dissipation due to their excellent thermal conductivity properties, ensuring the longevity and performance of electronic components. 5. Industrial applications: Aluminum sheets find applications in various industrial sectors, including aerospace, marine, chemical, and energy. They are used for manufacturing heat exchangers, tanks, pipes, and other equipment, thanks to their corrosion resistance and high strength-to-weight ratio. 6. Decorative purposes: Aluminum sheets are also utilized for decorative purposes in architecture and interior design. They can be easily shaped, colored, and textured to create attractive facades, wall panels, ceilings, and furniture. 7. Reflective surfaces: Aluminum sheets are commonly used for their reflective properties. They are used in mirrors, solar panels, light fixtures, and reflective signage to enhance brightness and improve energy efficiency. In summary, aluminum sheets are widely used in multiple industries due to their exceptional properties. Their lightweight, durability, corrosion resistance, and thermal conductivity make them a preferred choice for construction, transportation, packaging, electronics, industrial applications, decoration, and reflective surfaces.

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically consists of 99.5% pure aluminum with trace amounts of other elements such as iron and silicon.

- Q: Are 101 aluminum sheets suitable for outdoor signage?

- Outdoor signage can indeed be made from 101 aluminum sheets, which possess the necessary qualities for such purposes. Aluminum is renowned for its ability to endure and resist weathering, rendering it a perfect material for outdoor applications. The 101 aluminum alloy, in particular, has been crafted to possess exceptional strength and resistance against corrosion, making it even more suitable for outdoor signage. It can withstand harsh weather conditions, including rain, snow, UV exposure, and temperature fluctuations, without succumbing to corrosion or deterioration. Moreover, aluminum sheets are lightweight, facilitating their installation and transportation. All in all, 101 aluminum sheets offer a dependable and enduring solution for outdoor signage.

- Q: How do you remove stains or marks from aluminum sheets?

- To effectively eliminate stains or marks on aluminum sheets, the following steps can be followed: 1. Begin by preparing a mixture of warm water and mild dish soap in a bucket or basin. 2. Immerse a soft cloth or sponge into the soapy water and gently scrub the affected area. It is important to avoid the use of abrasive materials or harsh chemicals that may cause scratches or damage to the aluminum surface. 3. In case of more stubborn stains, a paste can be created by combining baking soda with water. Apply the paste onto the stained area and allow it to sit for a few minutes before softly scrubbing it with a cloth or sponge. 4. If the stains persist, consider utilizing a non-abrasive cleaner specifically designed for aluminum surfaces. Adhere to the instructions provided by the manufacturer on the packaging for optimal outcomes. 5. Thoroughly rinse the aluminum sheet with clean water to eliminate any remnants of soap. 6. For particularly stubborn stains or marks that prove to be difficult to remove, white vinegar or lemon juice can be employed. Apply a small amount of vinegar or lemon juice onto a cloth or sponge and gently rub the stained area. Rinse the aluminum sheet thoroughly after utilizing these acidic solutions. 7. After the cleaning process, it is crucial to completely dry the aluminum sheet to prevent the formation of water spots or streaks. This can be achieved by using a clean towel or allowing the sheet to air dry. Always remember to test any cleaning solution or method on a small, inconspicuous area of the aluminum sheet before applying it to the entire surface. This will help ensure that no damage or discoloration occurs.

- Q: What is the typical torsional strength of aluminum sheets?

- The torsional strength of aluminum sheets can vary depending on factors such as alloy composition, thickness, and manufacturing process. However, aluminum sheets generally have good torsional strength compared to other materials. Commonly used aluminum alloys in sheet form, like 6061-T6 and 5052-H32, have torsional strengths ranging from approximately 22,000 to 40,000 psi. These values indicate the maximum torque the aluminum sheet can withstand before permanent deformation or fracturing. Torsional strength is just one aspect of aluminum sheet's overall mechanical properties. Tensile strength, yield strength, and elongation are other important factors in determining the suitability of aluminum sheets for specific applications. When choosing aluminum sheets for a torsional application, it is crucial to consider specific requirements and consult with material suppliers or engineers to ensure the selected aluminum sheet meets the desired torsional strength criteria.

- Q: Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable. Aluminum is a highly recyclable material, and the recycling process for aluminum sheets is relatively simple and efficient. Recycling aluminum sheets involves melting the metal down and reforming it into new sheets or other aluminum products. The recycling process for aluminum requires considerably less energy compared to the production of new aluminum, making it an environmentally-friendly option. Additionally, recycling aluminum sheets helps conserve natural resources and reduces the amount of waste sent to landfills. Therefore, it is encouraged to recycle aluminum sheets whenever possible to contribute to a more sustainable and eco-friendly future.

- Q: Are aluminum sheets suitable for chemical storage tanks?

- Yes, aluminum sheets can be suitable for chemical storage tanks depending on the specific requirements of the chemical being stored. Aluminum is known for its excellent corrosion resistance, which makes it suitable for storing many chemicals. It forms a protective oxide layer that prevents further corrosion, even when exposed to harsh environments. However, it is important to consider the compatibility of the chemical with aluminum. Some chemicals, such as strong acids or bases, may react with aluminum and cause corrosion or other undesirable reactions. In such cases, alternative materials like stainless steel or fiberglass-reinforced plastic (FRP) may be more suitable. Additionally, the thickness and grade of the aluminum sheets should be chosen carefully based on the specific chemical being stored and the tank's intended use. Thicker sheets may be necessary for storing highly corrosive or hazardous chemicals, while thinner sheets may be sufficient for less aggressive substances. Overall, aluminum sheets can be a suitable choice for chemical storage tanks, but it is crucial to carefully evaluate the chemical compatibility and select the appropriate thickness and grade of aluminum to ensure safe and reliable storage.

Send your message to us

Aluminum Sheets for Sale - Aluminium Profile Building Expansion Joints

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords