Aluminum Sheets 5032 - Continuous Casting Aluminium Coil AA1050 HO 3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Continuous Casting Aluminium Coil is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

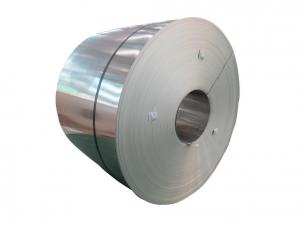

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1050 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a popular material for balcony railings due to its lightweight nature, durability, and resistance to corrosion. It is a versatile material that can be easily formed into different shapes and designs, making it suitable for various architectural styles. Additionally, aluminum railings require minimal maintenance and can withstand harsh weather conditions, making them a practical and long-lasting choice for balcony railings.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum is a lightweight material, making it ideal for use in vehicles as it helps reduce fuel consumption and increase overall efficiency. This is particularly important for industries such as aviation and automotive, where weight reduction is a key factor in improving performance. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in the transportation industry, where vehicles are exposed to various environmental conditions such as rain, snow, and road salt. Using aluminum sheets helps to extend the lifespan of vehicles and reduces maintenance costs associated with corrosion-related issues. Additionally, aluminum is highly recyclable, making it a more sustainable choice compared to other materials. The transportation industry is increasingly focusing on sustainability, and the use of aluminum sheets aligns with these goals. Recycling aluminum requires significantly less energy compared to producing it from raw materials, leading to reduced carbon emissions and energy consumption. Moreover, aluminum offers excellent formability and versatility. It can be easily molded into various shapes and sizes, allowing manufacturers to design lightweight yet strong structures. This flexibility in design enables the production of more aerodynamic vehicles, leading to improved fuel efficiency. Lastly, aluminum sheets have high strength-to-weight ratio, meaning they can provide the required strength while still being lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. Overall, the advantages of using aluminum sheets in the transportation industry include weight reduction, corrosion resistance, sustainability, formability, versatility, and high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: i know what aluminum is but oxide is not found on the periodic table, and the teacher also gave us a list of common oxidation numbers for polyatomic ions and it is not there also, can anyone help me?

- Mass Of Aluminum

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is a lightweight and durable material that offers a variety of benefits for automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, roofs, and other components. The use of aluminum sheets in automotive applications helps to reduce the overall weight of the vehicle, which improves fuel efficiency and performance. Additionally, aluminum has excellent corrosion resistance properties, making it ideal for withstanding harsh weather conditions and road salt exposure. Furthermore, aluminum can be easily formed and shaped, allowing for complex designs and intricate detailing on automotive parts. Overall, the use of aluminum sheets in automotive applications contributes to the production of lighter, more fuel-efficient, and aesthetically appealing vehicles.

- Q: Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Aluminum is a versatile material that can be easily shaped, cut, and formed into various designs, making it ideal for decorative applications. It can be used to create decorative panels, sculptures, signage, furniture, and many other decorative elements. Additionally, aluminum can be anodized or painted in a wide range of colors, allowing for further customization and enhancing its aesthetic appeal. Its lightweight nature and resistance to corrosion also make it a practical choice for both indoor and outdoor decorative purposes.

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is an excellent conductor of heat, and its high thermal conductivity makes it an ideal material for dissipating heat generated by LED lights. The use of aluminum sheets as heat sinks helps to transfer the heat away from the LED chips, preventing overheating and prolonging the lifespan of the LED lighting system. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular choice for heat sink applications in LED lighting.

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- One way to determine the thickness tolerance of an aluminum sheet is by referring to the industry standards or specifications for aluminum sheet thicknesses. These standards outline the acceptable range of thickness variations and provide tolerance values. Additionally, using precision measuring tools such as micrometers or calipers, you can directly measure the thickness at various points on the sheet and compare it to the specified tolerance range to determine if it meets the required thickness tolerance.

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- I believe your problem is that concrete acts as a fairly strong base (this is especially true of mortar mixes). It is well known that strong base will react with an active metal like aluminium and produce hydrogen gas as a byproduct. The representative reaction is: 2Al+6NaOH==2Na3AlO3+3H2, This reaction is fairly rapid and can even cause an explosive buildup of hydrogen gas in a non-ventillated area.

Send your message to us

Aluminum Sheets 5032 - Continuous Casting Aluminium Coil AA1050 HO 3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords