Black Anodized Aluminum Sheets 4x8 - Aluminum Sheet, Plates, 5 Bars, Stucco

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

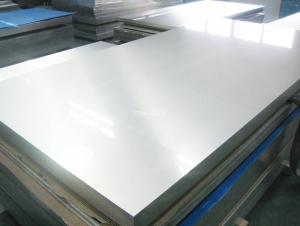

1.Structure of Aluminum Sheet,Plates, 5 bars,Stucco :

Aluminum Sheet,plates, 5 bars,stuccois widely used for decorative purposes in construction, packing and appliance. Aluminum Sheet,plates, 5 bars,stucco is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Aluminum Sheet,Plates, 5 bars,Stucco

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Sheet,Plates, 5 bars,Stucco

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminum Sheet,Plates, 5 bars,Stucco

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- answer is 0.47/107 so each atom weighs 0.004392523364485981308411214953271g that can be rounded to whatever decimal places you want.

- Q: Are aluminum sheets suitable for water storage applications?

- Yes, aluminum sheets are suitable for water storage applications. Aluminum is a lightweight and durable material that is highly resistant to corrosion and rust. It is also impermeable to light, air, and water, making it an excellent choice for storing water. Additionally, aluminum sheets can be easily formed into various shapes and sizes, allowing for customizable water storage solutions.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q: What is the width and length of the aluminum sheets?

- The width and length of the aluminum sheets may vary depending on the specific product or manufacturer. It is recommended to refer to the product specifications or contact the manufacturer for accurate measurements.

- Q: Can aluminum sheets be used in the automotive industry?

- Aluminum sheets indeed find application in the automotive sector. Being a lightweight and sturdy material, aluminum offers several advantages when it comes to manufacturing automobiles. Car bodies, hoods, doors, and other structural components are commonly produced using aluminum. This helps in reducing the weight of the vehicle, resulting in improved fuel efficiency and enhanced performance. Furthermore, aluminum exhibits remarkable resistance to corrosion, making it ideal for vehicles that face harsh weather conditions. Moreover, aluminum sheets are easily formed, welded, and joined, which adds to their versatility and suitability for various automotive purposes. Consequently, the automotive industry widely embraces the utilization of aluminum sheets due to their numerous benefits.

- Q: Can the aluminum sheets be used for manufacturing architectural sunshades?

- Yes, aluminum sheets can be used for manufacturing architectural sunshades. Aluminum is a lightweight and durable material that is commonly used in the construction industry for various purposes, including sunshades. It offers excellent resistance to corrosion and can withstand outdoor exposure, making it suitable for architectural applications. Additionally, aluminum sheets can be easily customized and fabricated into different shapes and sizes, allowing for flexibility in design.

- Q: What are the different methods of surface engraving aluminum sheets?

- There are several methods of surface engraving aluminum sheets, each offering unique advantages and suitable for different applications. 1. Mechanical Engraving: This traditional method involves using a rotating cutting tool, such as a milling machine or a router, to physically remove material from the surface of the aluminum sheet. It is a precise and versatile technique that can create intricate designs and deep engravings. Mechanical engraving is commonly used for signage, branding, and decorative purposes. 2. Laser Engraving: This modern and highly precise method uses a laser beam to vaporize or melt the surface of the aluminum sheet, creating a permanent mark. Laser engraving offers great control over the depth, speed, and intensity of the engraving, allowing for detailed and accurate results. It is widely used in industries like aerospace, automotive, and electronics for part identification, serial numbers, and barcodes. 3. Chemical Etching: Also known as chemical milling or photochemical machining, this process involves coating the aluminum sheet with a photosensitive mask and exposing it to UV light through a stencil or artwork. The exposed areas are then chemically etched, removing the material and creating the desired design. Chemical etching offers high precision, repeatability, and the ability to engrave very thin lines or complex patterns. It is often used in electronic components, nameplates, and decorative applications. 4. Diamond Drag Engraving: This method uses a diamond-tipped stylus that is dragged across the surface of the aluminum sheet, scratching or indenting it to create the engraving. Diamond drag engraving is commonly used for industrial applications, such as part identification and serial numbering, as well as for creating durable and long-lasting markings on aluminum sheets. 5. Rotary Engraving: In this technique, a rotating cutting tool is used to remove the material from the aluminum sheet, similar to mechanical engraving. However, rotary engraving is typically used for larger and thicker aluminum sheets and is often employed in industrial settings for marking, labeling, and identification purposes. Each of these methods has its own advantages and is suitable for different applications, so choosing the right engraving method for aluminum sheets depends on factors such as the desired design, level of detail, durability requirements, and the intended use of the engraved product.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. It is a commonly used material due to its high thermal conductivity, lightweight nature, and excellent heat resistance properties.

- Q: Are aluminum sheets suitable for chemical storage tanks?

- Depending on the specific requirements of the chemical being stored, aluminum sheets may be a suitable option for chemical storage tanks. Aluminum is renowned for its exceptional resistance to corrosion, making it well-suited for the storage of numerous chemicals. It develops a protective oxide layer that effectively prevents further corrosion, even in harsh environments. Nevertheless, it is vital to take into account the compatibility between the chemical and aluminum. Some chemicals, such as strong acids or bases, can react with aluminum, leading to corrosion or other undesirable reactions. In such instances, alternative materials like stainless steel or fiberglass-reinforced plastic (FRP) might be more appropriate. Furthermore, careful consideration should be given to the thickness and grade of the aluminum sheets, depending on the specific chemical being stored and the intended use of the tank. For highly corrosive or hazardous chemicals, thicker sheets may be necessary, while thinner sheets may suffice for less aggressive substances. In conclusion, aluminum sheets can be a viable choice for chemical storage tanks, provided that careful evaluation of chemical compatibility is conducted and the appropriate thickness and grade of aluminum are selected to ensure safe and reliable storage.

Send your message to us

Black Anodized Aluminum Sheets 4x8 - Aluminum Sheet, Plates, 5 Bars, Stucco

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords