Aluminum Bronze Coil for Aluminum Ceiling 1 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Color Coated Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

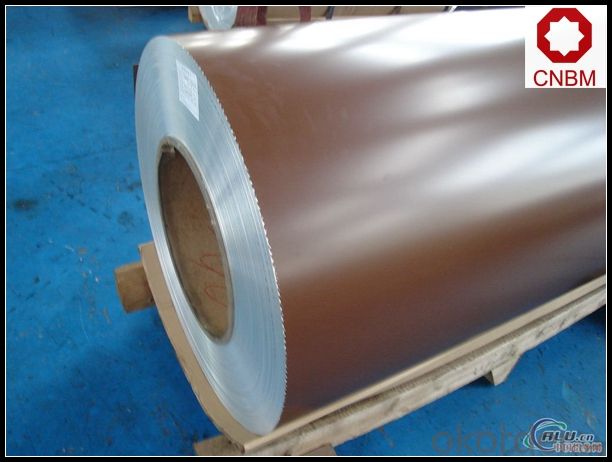

5. Image of Color Coated Aluminum Coil

6. Package and shipping of Color Coated Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Difference between aluminium roll gate and iron roll gate

- Structurally, there is no difference, but the aluminum roll gate weight is light, the motor needs little effect, save power; and the iron roll gate weight, motor power, electricity, but the door of high strength, better safety performance.

- Q: How do I deal with too much aluminum powder when the aluminum strips are divided?

- At present, dust removal system distribution bag filter and water dust collector two kinds.

- Q: This question asks for methods to determine the age of an aluminum coil, distinguishing between new and old.

- <p>To determine if an aluminum coil is new or old, you can look for several indicators: the surface condition, such as scratches or signs of wear; the quality of the protective coating, if any, which may degrade over time; the manufacturing date or batch number, if available; and the overall appearance and shine. New coils typically have a smooth, shiny surface with no significant scratches or dents, and a consistent protective coating. Old coils may show signs of oxidation, discoloration, or other forms of degradation. Additionally, testing the coil's physical properties, such as tensile strength, can provide clues about its age, as these properties can degrade over time.</p>

- Q: Can aluminum coils be used in the manufacturing of cans?

- Yes, aluminum coils can be used in the manufacturing of cans. Aluminum coils are commonly used in the canning industry as they are lightweight, durable, and provide excellent sealability, ensuring the freshness and preservation of the contents.

- Q: What are the benefits of using aluminum coils?

- There are several benefits of using aluminum coils. Firstly, aluminum is a lightweight material, making it easier to handle and install. Secondly, aluminum is highly resistant to corrosion, ensuring the durability and longevity of the coils. Additionally, aluminum coils have excellent heat transfer properties, allowing for efficient cooling or heating. Lastly, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice.

- Q: What is the lifespan of aluminum coils?

- The lifespan of aluminum coils can vary depending on various factors such as the quality of the coil, installation method, maintenance practices, and environmental conditions. However, on average, aluminum coils can last anywhere from 10 to 20 years or even longer with proper care and maintenance.

- Q: What’s the difference between natural cooling and slice cooling?

- Cooling with furnace means after thermal insulation, stop heating furnace and make the parts in the furnace cool slowly to the room temperature with the furnace. Natural cooling is a kind of cooling method utilizing fluid circulation based on the fact that density varies with temperature to remove hea

- Q: What are the rules and guidelines that govern the transport of aluminum coils?

- <p>Yes, there are specific regulations for the transportation of aluminum coils. These include adhering to weight limits, ensuring proper packaging to prevent damage, and following guidelines for secure loading and unloading. Compliance with hazardous materials regulations is also crucial if the coils are being transported internationally. It's important to check with the specific transportation authority or consult the International Air Transport Association (IATA) and International Maritime Dangerous Goods (IMDG) codes for detailed guidelines.</p>

- Q: Which is more unhealthy the bleached parchment paper or the aluminum from the pan?

- it would depend on what you're making i'd assume

- Q: The user is asking if it's possible to purchase recycled aluminum coil through online platforms.

- <p>Yes, you can buy recycled aluminum coil online. Many online marketplaces and specialized metal supply websites offer a variety of aluminum coils, including recycled ones. You can search for suppliers on platforms like Alibaba, Amazon, or industry-specific B2B websites. Be sure to check the supplier's reputation, the quality of the recycled aluminum, and the specifications to ensure it meets your requirements.</p>

Send your message to us

Aluminum Bronze Coil for Aluminum Ceiling 1 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords